Polysulfone/polyvinyl alcohol composite anion exchange membrane and preparation method thereof

A technology of compound anion and polyvinyl alcohol, which is applied in the preparation of the polysulfone/polyvinyl alcohol compound anion exchange membrane, and the field of polysulfone/polyvinyl alcohol compound anion exchange membrane, can solve the problems of dimensional stability and poor alkali resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A kind of preparation method of polysulfone / polyvinyl alcohol composite anion exchange membrane of the present invention, concrete steps are as follows:

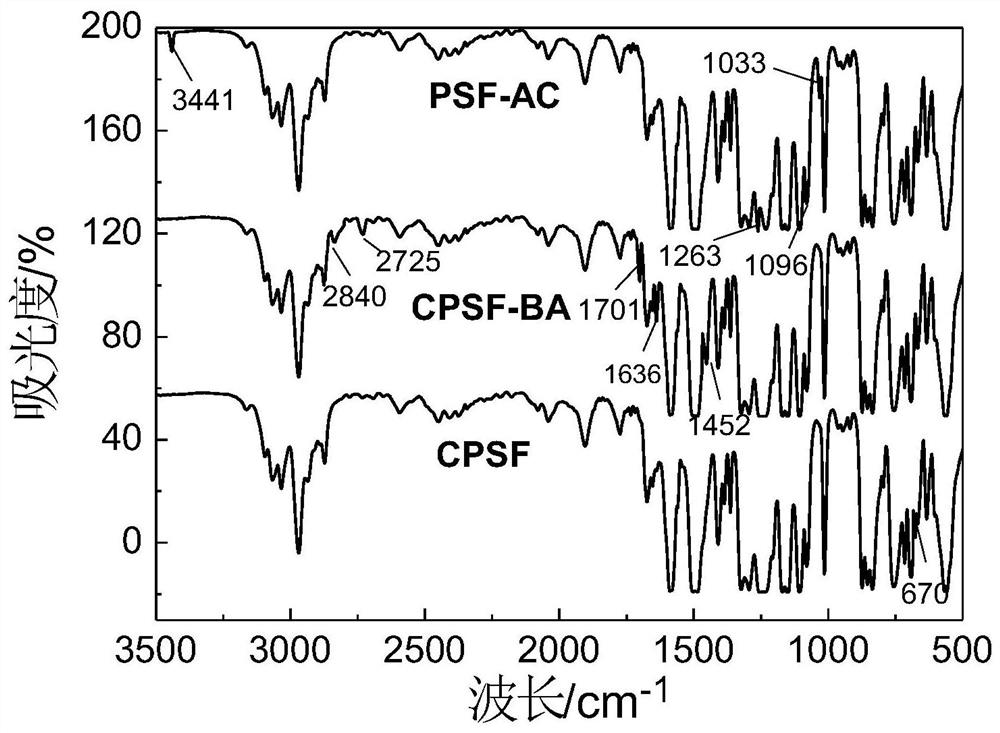

[0036] Step 1: Prepare chloromethylated polysulfone (CPSF), the specific steps are as follows:

[0037] Dissolve PSF in dichloromethane, add catalyst SnCl after it dissolves 4 At the same time, drop the chloromethylation reagent 1,4-dichloromethoxybutane with a dropping funnel, react at 40-60°C for 24-40h, and then add 2-4mol / L of dilute hydrochloric acid, and then add a precipitant to precipitate the product, leave it to stand, separate, wash, and dry to obtain chloromethylated polysulfone (CPSF);

[0038] Among them, the mass ratio of polysulfone, methylene chloride, 1,4-dichloromethoxybutane and tin tetrachloride is: 1:47:1.9:0.58;

[0039] The precipitant is any one or more of absolute ethanol, methanol, and isopropanol;

[0040] Among them, the preparation method of 1,4-dichloromethoxybutane is as follows: mix...

Embodiment 1

[0062] A kind of preparation method of polysulfone / polyvinyl alcohol composite anion exchange membrane of the present invention, concrete steps are as follows:

[0063] Step 1: Prepare chloromethylated polysulfone (CPSF), the specific steps are as follows:

[0064] Dissolve PSF in dichloromethane, add catalyst SnCl after it dissolves 4 At the same time, use a dropping funnel to drop the chloromethylation reagent 1,4-dichloromethoxybutane, react at 40-60°C for 24h, then add 2mol / L dilute hydrochloric acid to the reaction mixture, and then Adding a precipitant to precipitate the product, standing, separating, washing, and drying to obtain chloromethylated polysulfone (CPSF);

[0065] Among them, the mass ratio of polysulfone, methylene chloride, 1,4-dichloromethoxybutane and tin tetrachloride is: 1:47:1.9:0.58;

[0066] Precipitating agent is absolute ethanol;

[0067] Step 2: Prepare modified polysulfone (CPSF-BA) with aldehyde groups at the end of the side chain; specifical...

Embodiment 2

[0077] A kind of preparation method of polysulfone / polyvinyl alcohol composite anion exchange membrane of the present invention, concrete steps are as follows:

[0078] Step 1: Prepare chloromethylated polysulfone (CPSF), the specific steps are as follows:

[0079] Dissolve PSF in dichloromethane, add catalyst SnCl after it dissolves 4 At the same time, use a dropping funnel to drop the chloromethylation reagent 1,4-dichloromethoxybutane, react at 50°C for 32h, then add 3mol / L dilute hydrochloric acid to the reaction mixture, and then add the precipitate The product is precipitated by the agent, left standing, separated, washed and dried to obtain chloromethylated polysulfone (CPSF);

[0080] Among them, the mass ratio of polysulfone, methylene chloride, 1,4-dichloromethoxybutane and tin tetrachloride is: 1:47:1.9:0.58; the precipitation agent is methanol;

[0081] Step 2: Prepare modified polysulfone (CPSF-BA) with aldehyde groups at the end of the side chain; specifically:...

PUM

| Property | Measurement | Unit |

|---|---|---|

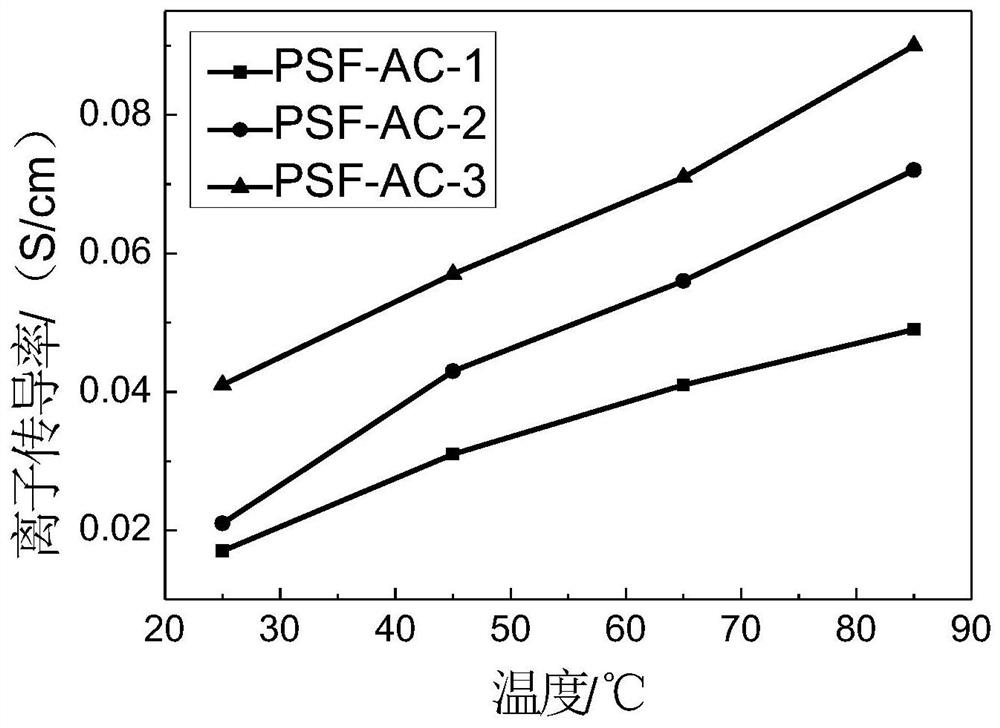

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com