Sealing assembly for an industrial gate valve and valve comprising such sealing assembly

A sealing component and sealing element technology, applied in the direction of engine sealing, sliding valve, valve device, etc., can solve the problems of complex manufacturing, reduce wear and fatigue deterioration, increase sealing effect, and reduce valve opening force value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

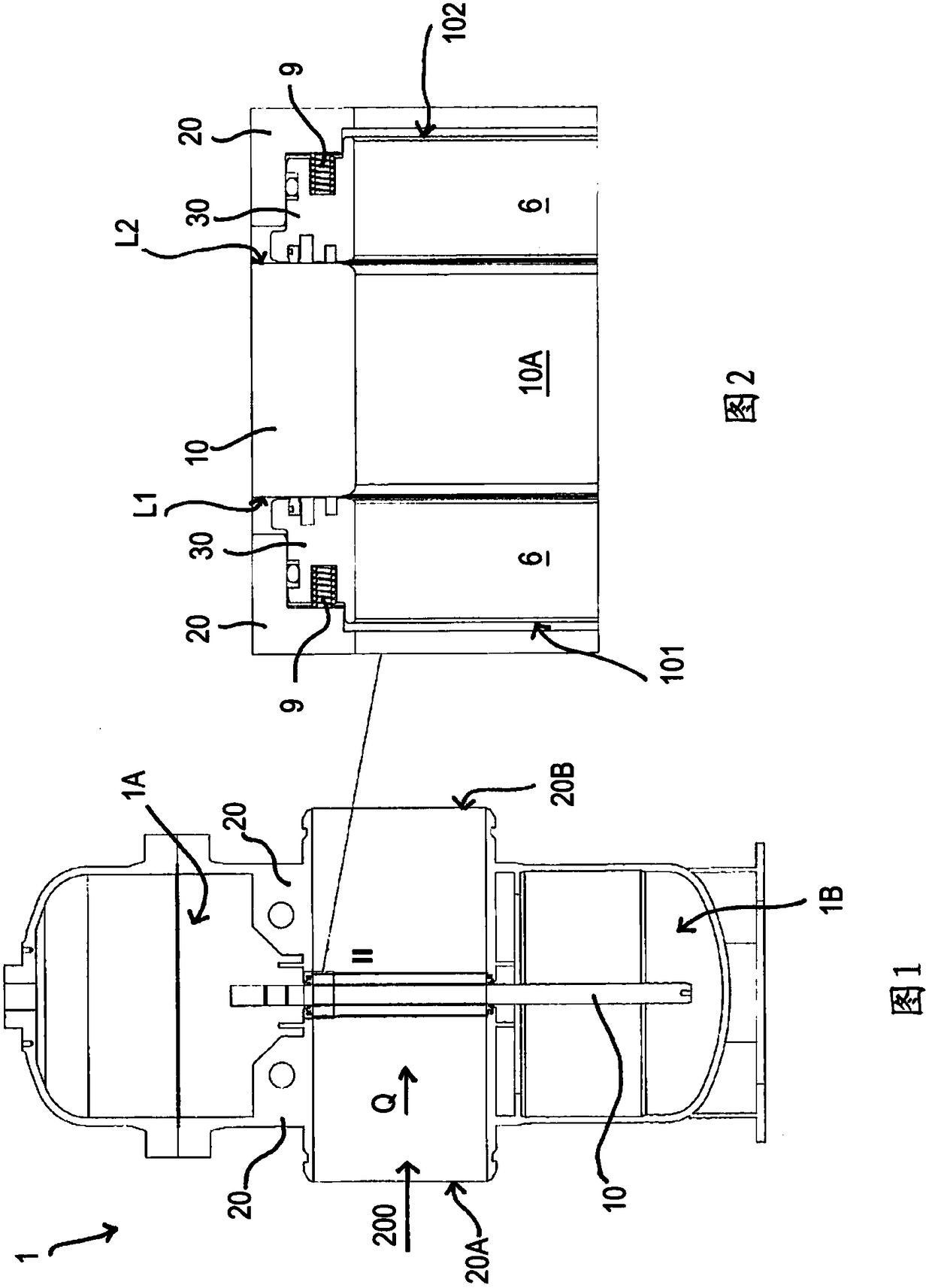

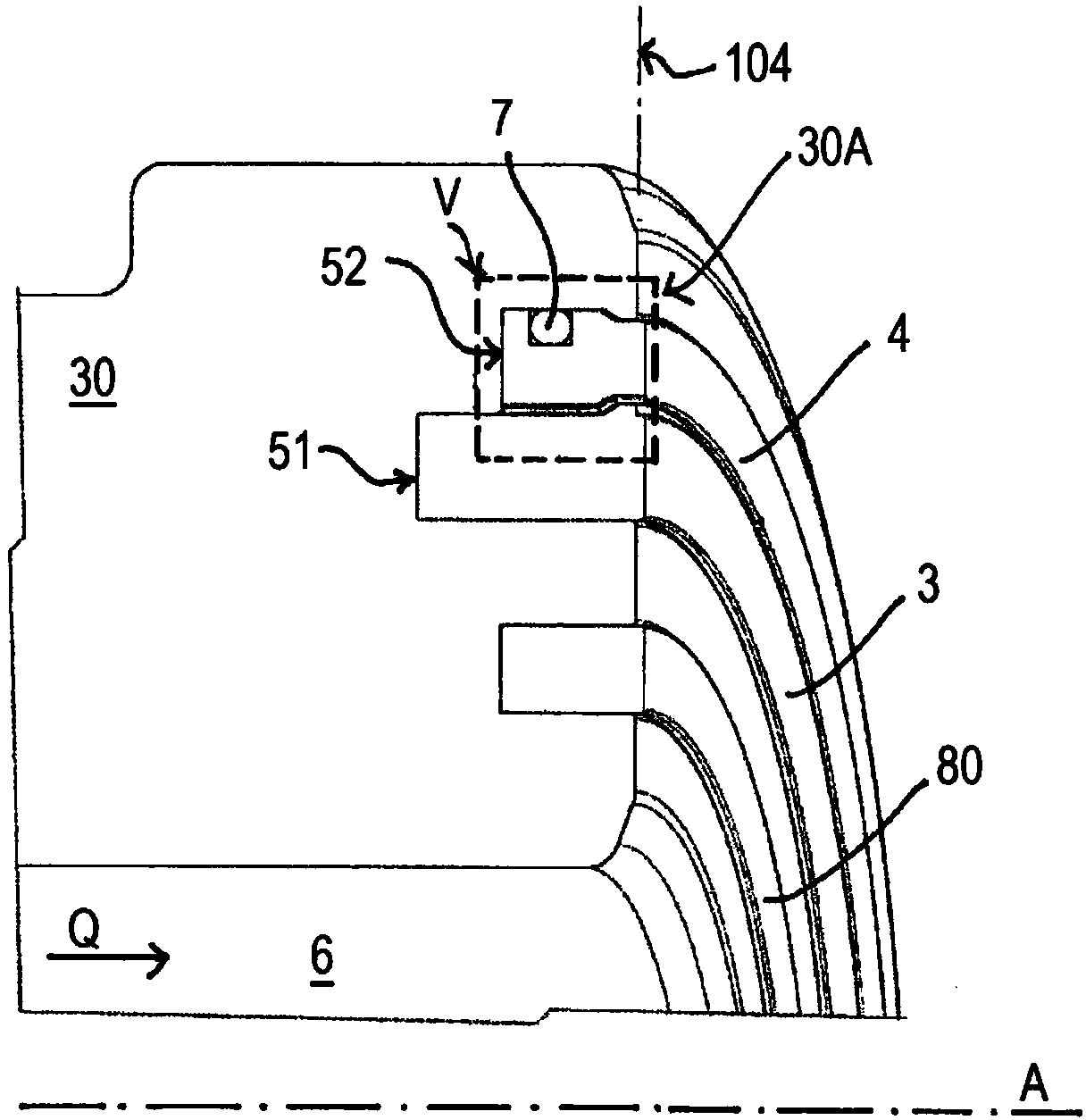

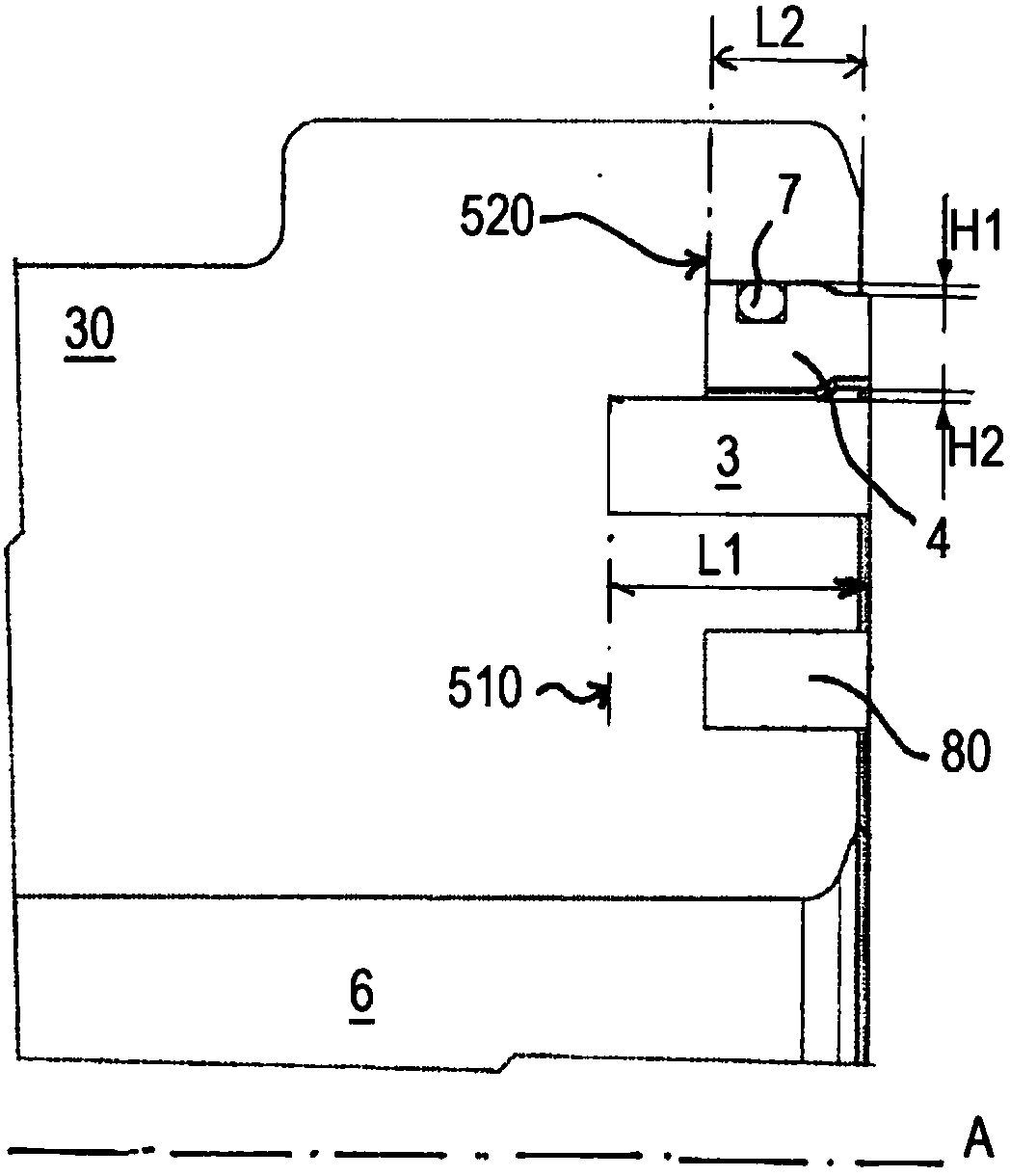

[0029] figure 1 Shown is a gate valve 1 comprising a sealing assembly according to the invention. The valve 1 is intended to be mounted on a fluid conduit and comprises a body 20 delimiting a housing housing the shutter 10 . According to principles known per se, the shutter 10 is correspondingly movable between an open position and a closed position to allow flow Q to pass between the inlet section 20A and the outlet section 20B delimited by the body 20 or Fail.

[0030] According to the present invention, figure 1 The valve 1 shown in includes a first sealing assembly 101 and a second sealing assembly 102 operable to achieve a fluid seal on opposite sides L1 , L2 of the shutter 10 . To this end, a first sealing assembly 101 and a second sealing assembly 102 are operatively mounted respectively upstream and downstream of the shutter 10 with respect to a flow direction 200 defined by the body 20 of the valve 1 .

[0031] shown as an example only figure 1 In the preferred e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com