Filter sealing performance automatic detection device

An automatic detection device, a technology of tightness detection, which can be used in the use of liquid/vacuum for liquid tightness measurement, by detecting the appearance of fluid at the leak point, etc., which can solve the problems of low detection efficiency, poor detection stability and reliability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

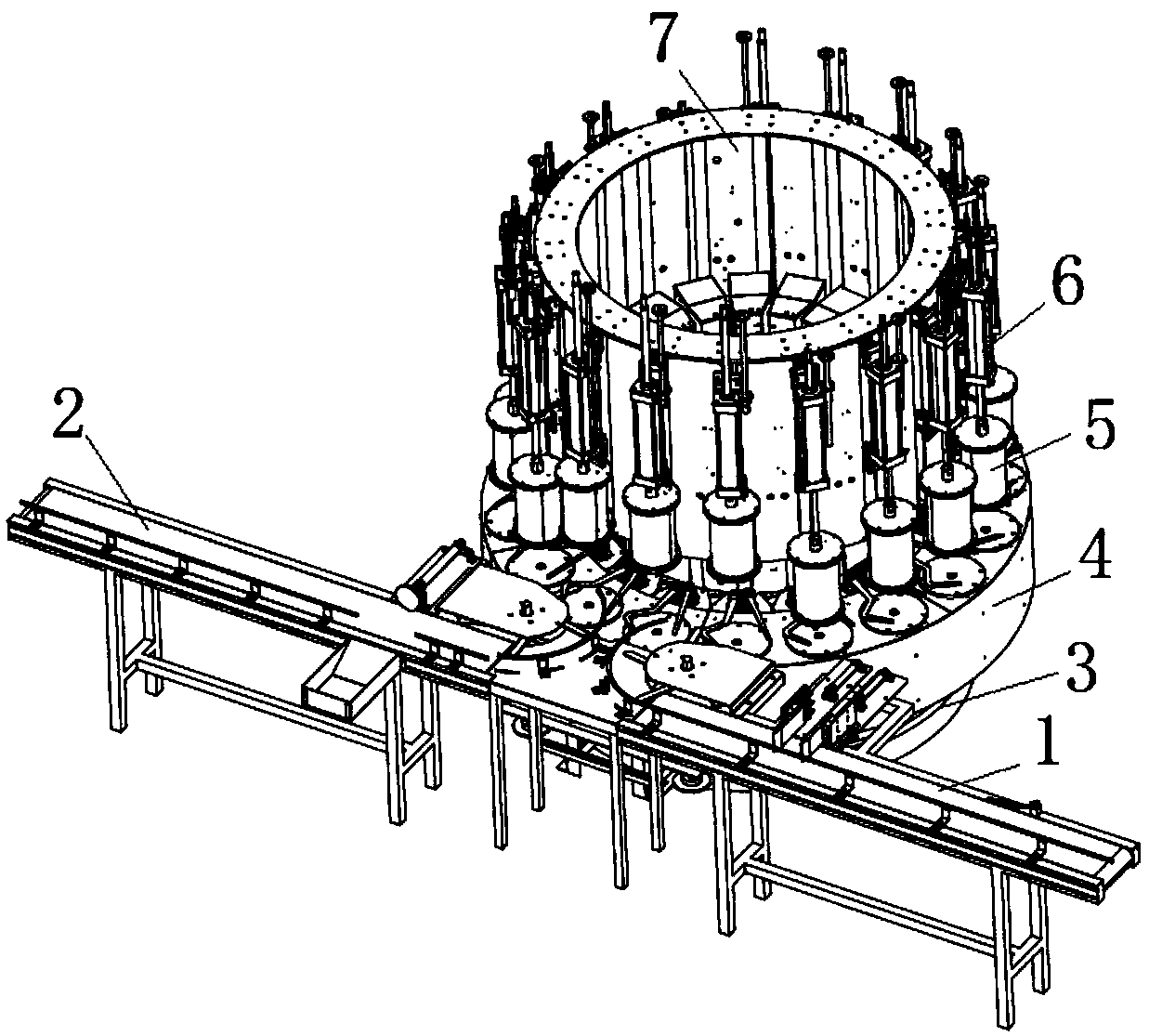

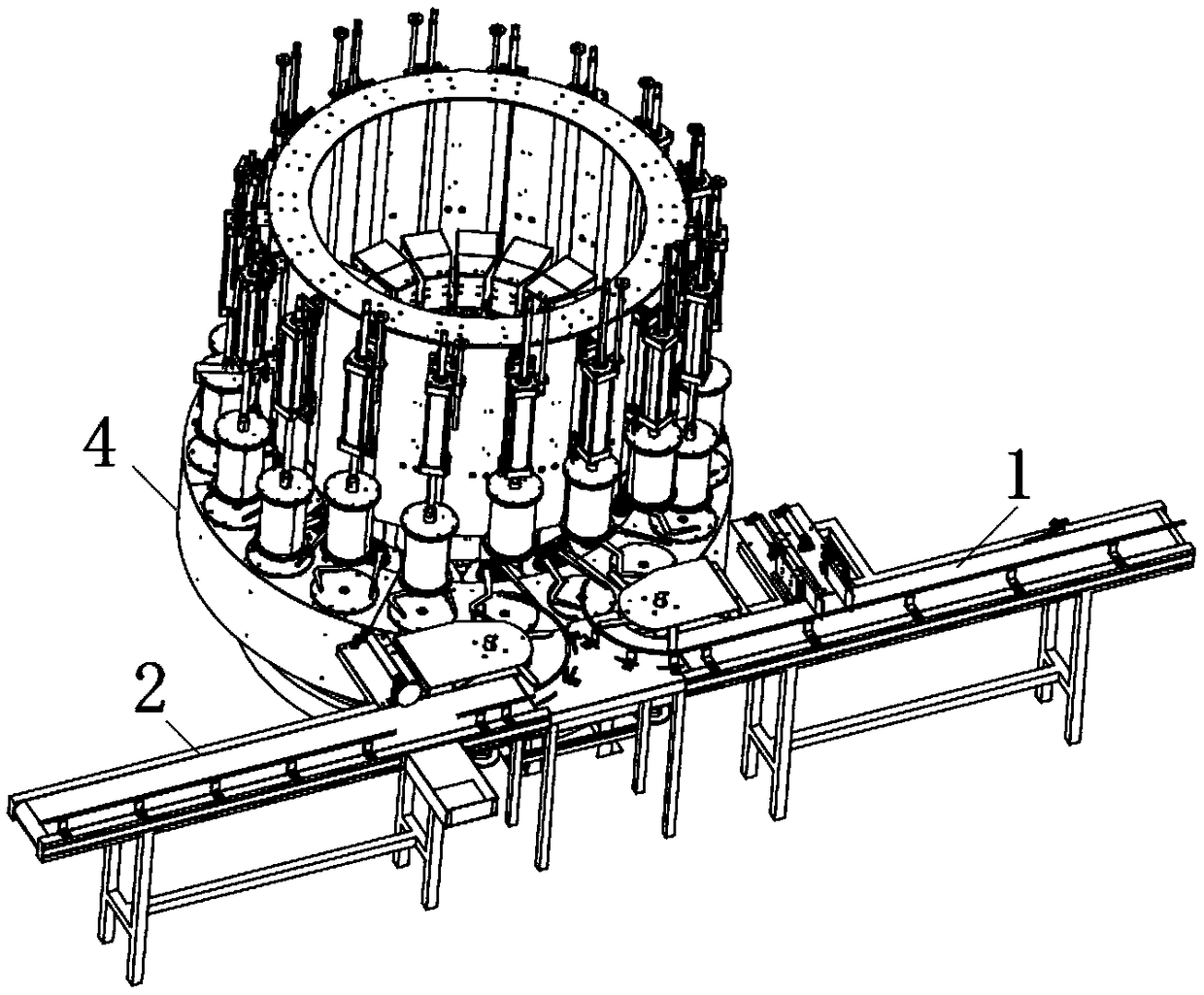

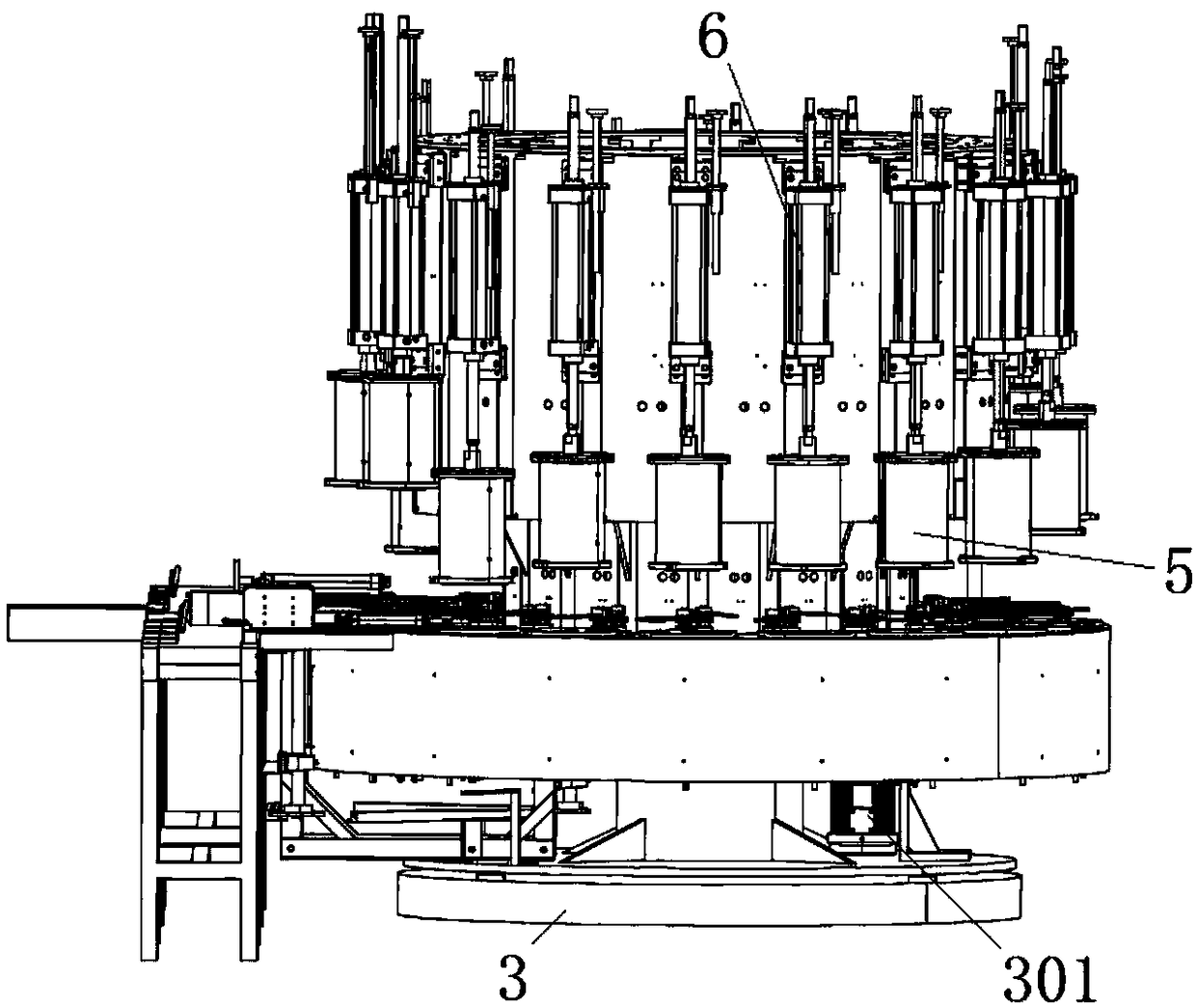

[0121] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

[0122] Such as Figure 1 to Figure 16 As shown, the filter airtightness automatic detection device includes an upper piece conveying mechanism 1, a filter airtightness detection mechanism and a lower piece conveyance mechanism 2; wherein, the filter airtightness detection mechanism includes a detection platform 401 and is located on The air cover 5 that can be pressed down above the detection platform is provided with an air nozzle 504, and the corresponding air cover is provided with a tight structure that can tighten the filter port on the detection platform. Air holes for air intake in the filter cavity.

[0123] The vertical filter to be tested is transported to the detection platform through the upper conveying mechanism. The lower opening of the filter is located on the detection platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com