Equipment for testing stability of power cabinet

A testing equipment and robustness technology, used in impact testing, machine/structural component testing, measuring devices, etc., and can solve problems such as large resource consumption, long time consumption, and many testing steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

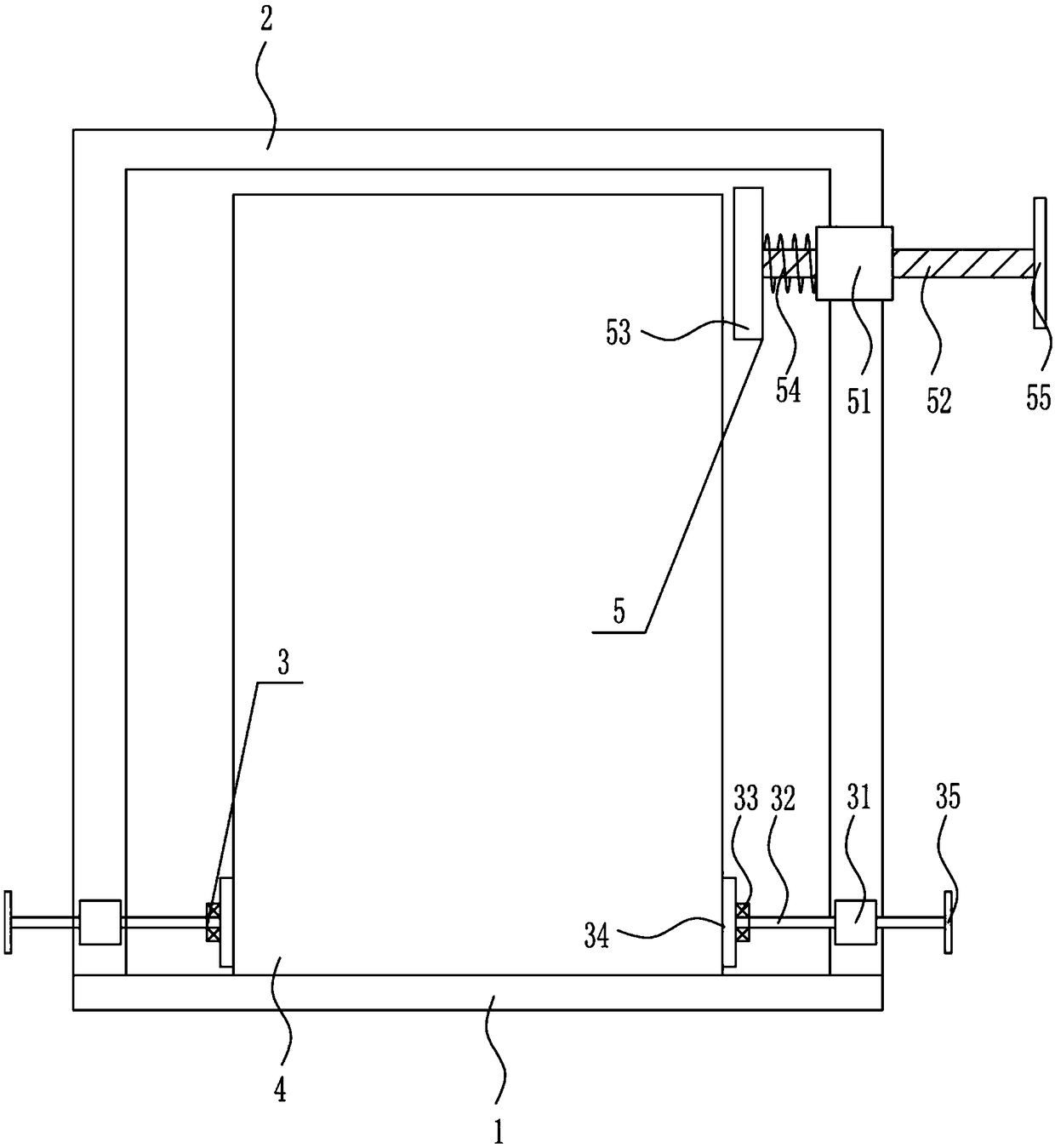

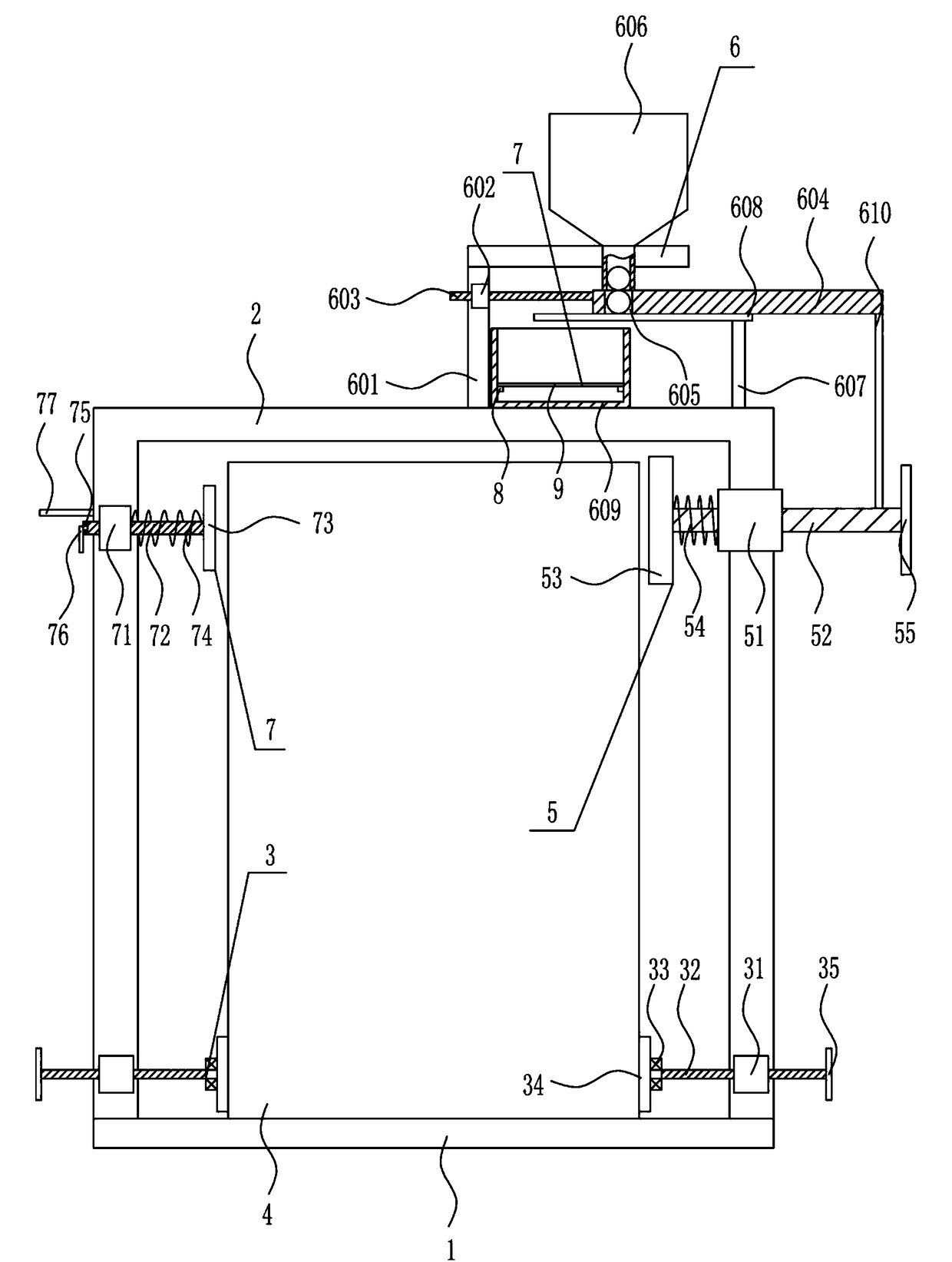

[0026] A power cabinet stability test equipment, such as Figure 1-2 As shown, it includes a base plate 1, an N-type frame 2, a fixing mechanism 3 and a testing mechanism 5. An N-type frame 2 is installed on the top of the base plate 1, a fixing mechanism 3 is installed on the N-type frame 2, and the right side of the top of the N-type frame 2 is installed. A test mechanism 5 is installed.

Embodiment 2

[0028] A power cabinet stability test equipment, such as Figure 1-2 As shown, it includes a base plate 1, an N-type frame 2, a fixing mechanism 3 and a testing mechanism 5. An N-type frame 2 is installed on the top of the base plate 1, a fixing mechanism 3 is installed on the N-type frame 2, and the right side of the top of the N-type frame 2 is installed. A test mechanism 5 is installed.

[0029] The fixing mechanism 3 includes a nut 31, a bolt 32, a first bearing seat 33, a first pressing plate 34 and a turning block 35. The left and right sides of the bottom of the N-shaped frame 2 are symmetrically provided with nuts 31, and the nut 31 is provided with a matching bolt. 32. The opposite ends of the left and right bolts 32 are symmetrically installed with a first bearing seat 33, the other side of the first bearing seat 33 is provided with a first pressing plate 34, and the other end of the bolt 32 is provided with a turning block 35.

Embodiment 3

[0031] A power cabinet stability test equipment, such as Figure 1-2 As shown, it includes a base plate 1, an N-type frame 2, a fixing mechanism 3 and a testing mechanism 5. An N-type frame 2 is installed on the top of the base plate 1, a fixing mechanism 3 is installed on the N-type frame 2, and the right side of the top of the N-type frame 2 is installed. A test mechanism 5 is installed.

[0032] The fixing mechanism 3 includes a nut 31, a bolt 32, a first bearing seat 33, a first pressing plate 34 and a turning block 35. The left and right sides of the bottom of the N-shaped frame 2 are symmetrically provided with nuts 31, and the nut 31 is provided with a matching bolt. 32. The opposite ends of the left and right bolts 32 are symmetrically installed with a first bearing seat 33, the other side of the first bearing seat 33 is provided with a first pressing plate 34, and the other end of the bolt 32 is provided with a turning block 35.

[0033]The testing mechanism 5 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com