Rotating connection power supply bracket

A technology of rotating connection and screw connection, applied in the field of rotating connection power supply bracket, can solve problems such as difficulty in supplying power to rolling elements, and achieve the effects of avoiding poor contact, solving power supply difficulties, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

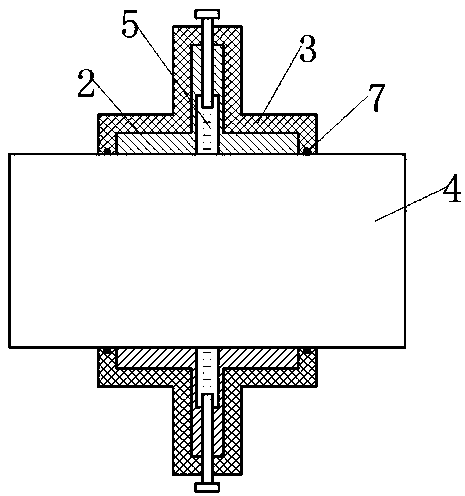

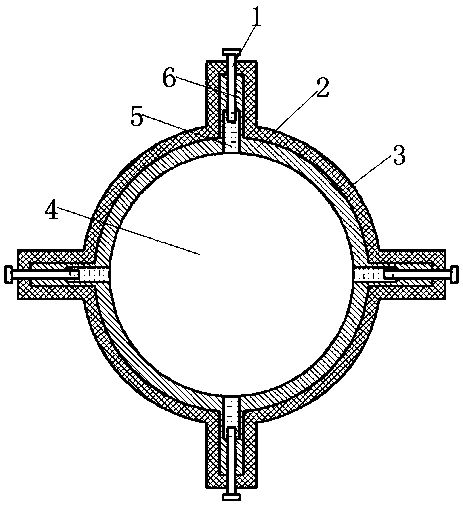

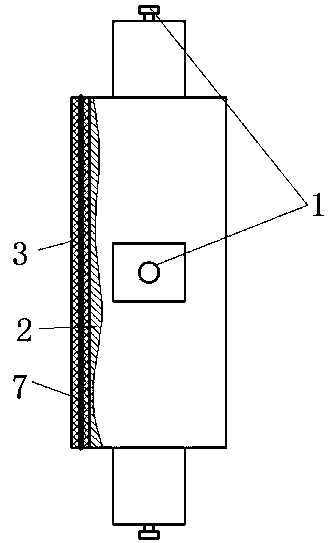

[0027] A rotating connection power supply bracket, the power supply bracket includes a slip ring 2, a support arm 6 and a terminal 1; the support arm 6 is integrally formed with the slip ring 2, and the front end of the support arm 6 is fixedly connected to the outer wall of the slip ring 2, Such as figure 1 As shown, the support arm 6 is perpendicular to the outer wall of the slip ring 2, so that the section at the joint between the slip ring 2 and the support arm 6 is in the shape of a "T"; the support arm 6 and the slip ring 2 are both conductors, and the inside of the support arm 6 An effusion cavity 5 is provided, the front end of the effusion cavity 5 extends toward the direction of the slip ring 2 and penetrates through the wall of the slip ring 2, forming an opening on the inner wall of the slip ring 2; a conductive liquid is arranged in the effusion cavity 5; There is also a threaded hole in the support arm 6, the front end of the threaded hole communicates with the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com