Heat-insulating and dustproof nail shooting device

A nail shooter and dust-proof technology, applied in nailing tools, U-shaped nailing tools, manufacturing tools, etc., can solve problems such as potential safety hazards, self-explosion of nail shooting bullets, and increased manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

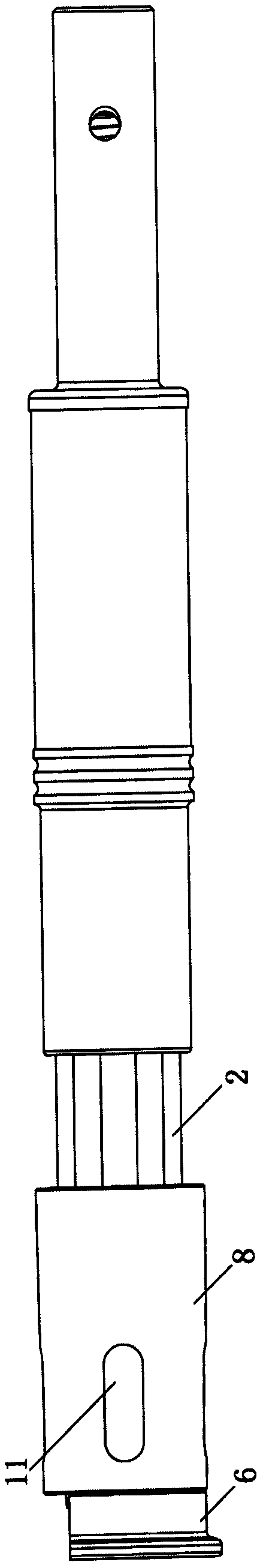

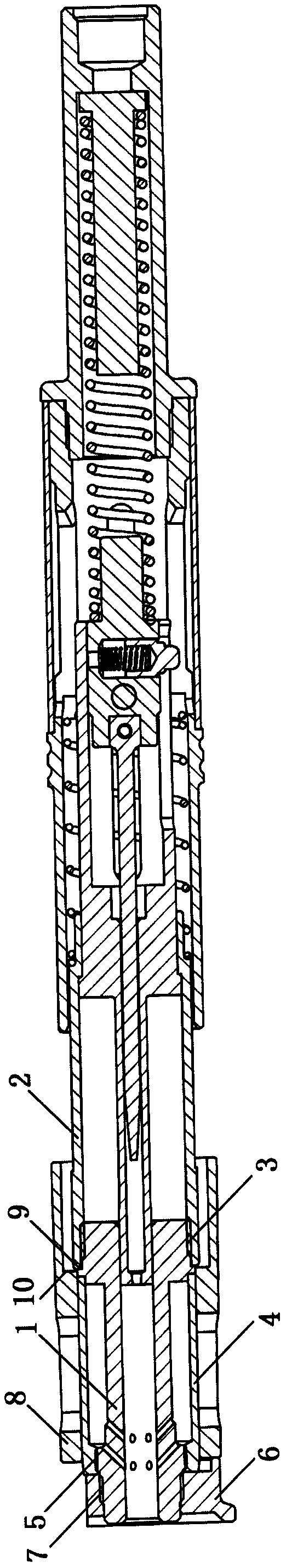

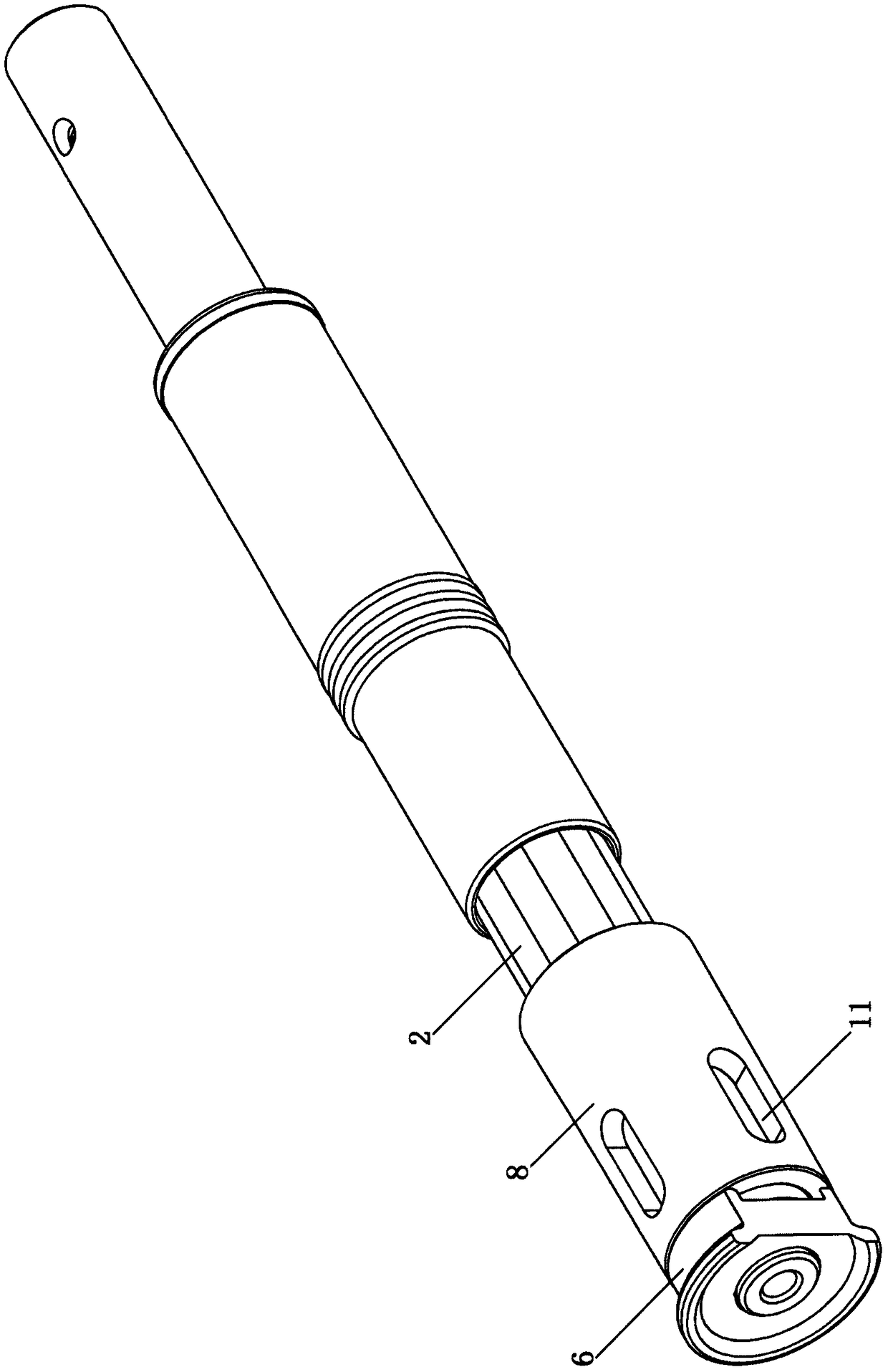

[0024] In the figure: 1 is the nail tube, 2 is the movable sleeve, 3 is the thread, 4 is the silencer sleeve, 5 is the thread, 6 is the dust cover, 7 is the thread, 8 is the heat insulation sleeve, 9 is the step A; 10 It is step B.

[0025] When in normal use, the dust cover 6 prevents the dust from falling. After firing, hold the non-hot heat insulation sleeve 8 and pull it back. The step B10 will force the movable cover 2 to move backward through the step A9 to realize the retreat. shell.

[0026] The action structure of the nail shooter, such as loading, firing, ejecting, and resetting, belongs to the conventional technology, and has been described in detail in the applicant's previous patent, so the description will not be repeated here.

[0027] When the screw thread 7 is damaged, a torsion force is applied between the movable sleeve 2 and the dust cover 6 to separate the two. Since the heat insulating sleeve 8 does not completely cover the movable sleeve 2 and the scre...

Embodiment 2

[0031] Heat dissipation through-holes 11 are arranged on the heat-insulating cover, which can dissipate internal heat, lower the temperature, and reduce potential safety hazards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com