Cleaning system facilitating cleaning of reagent bottles with different sizes

A technology for cleaning systems and pharmaceutical bottles, applied in the field of cleaning systems, can solve problems such as incomplete cleaning, and achieve the effect of improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

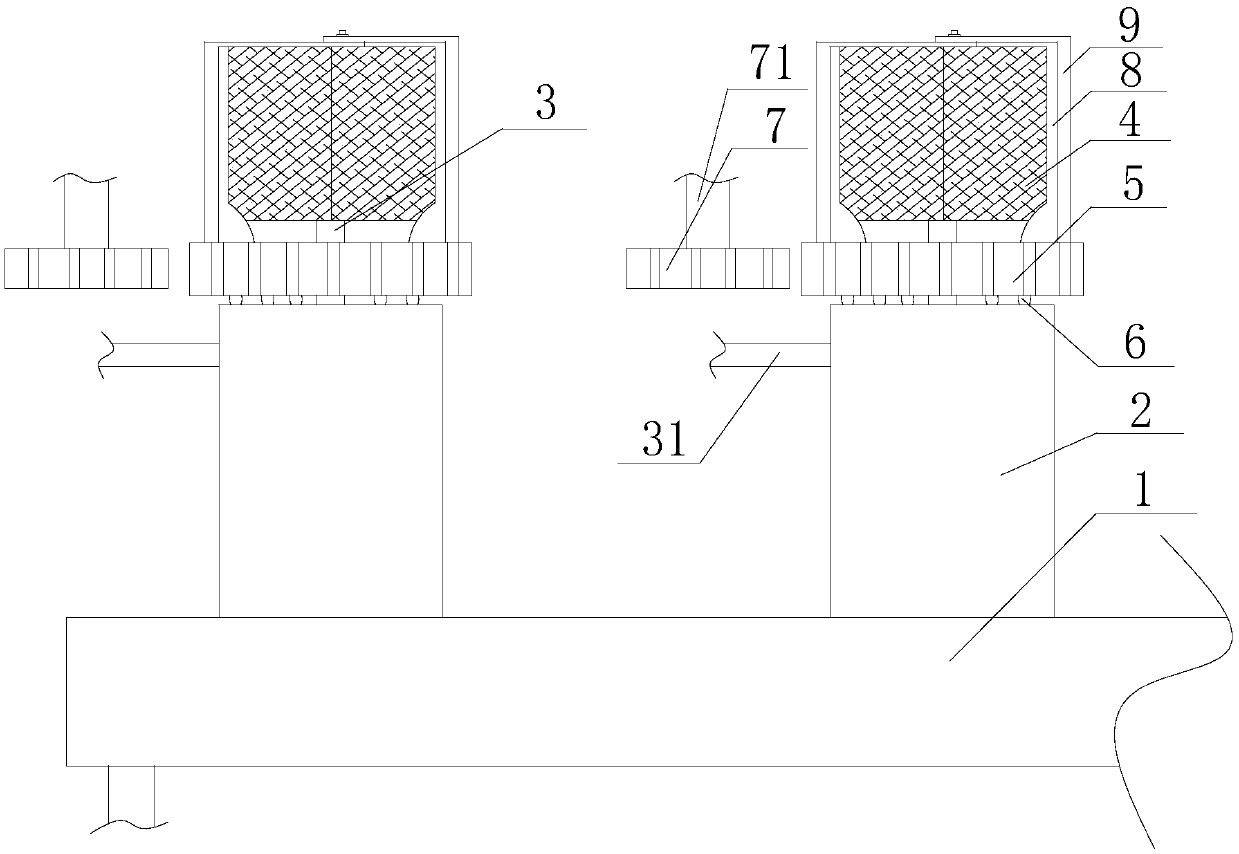

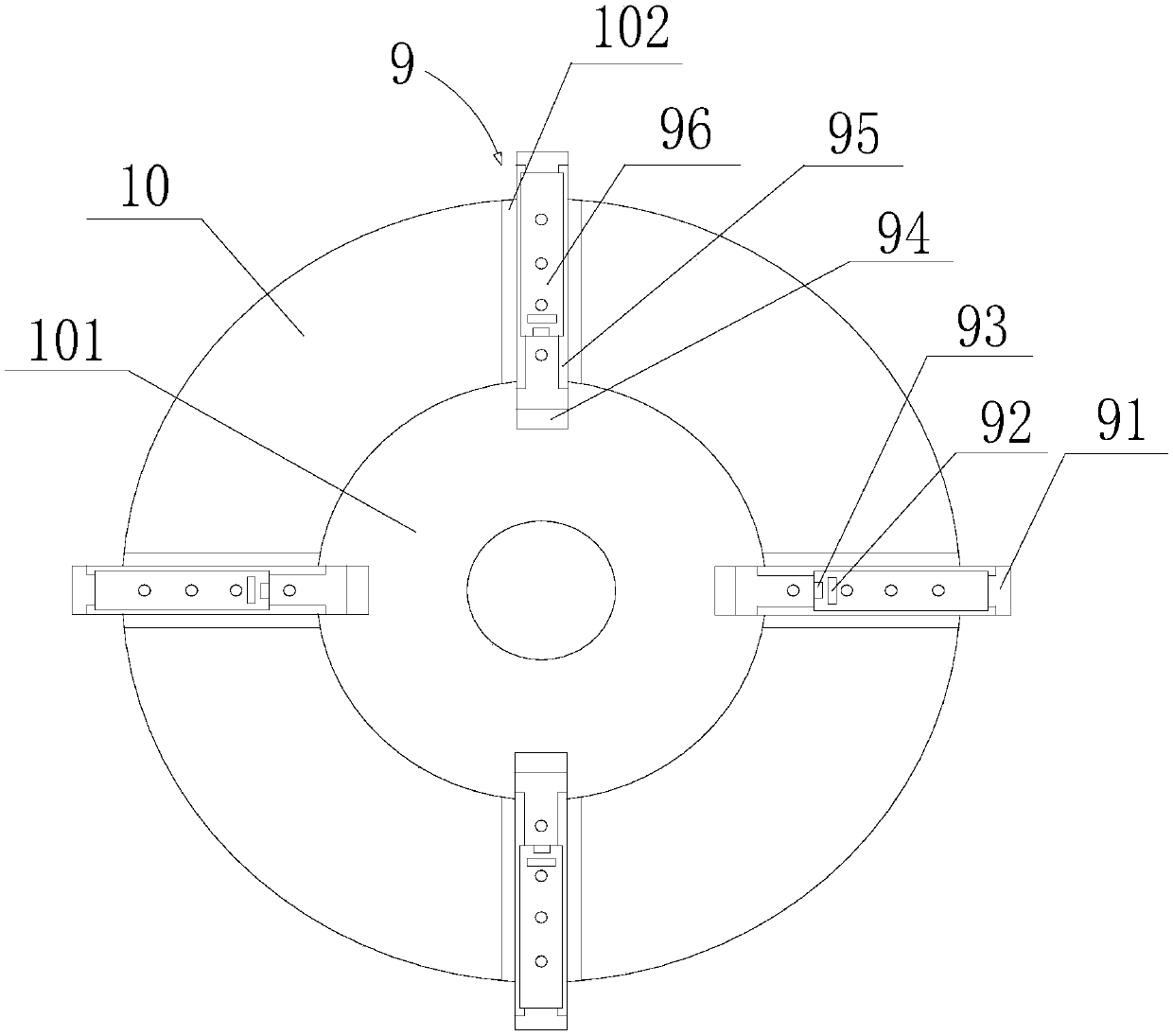

[0035] like figure 1 , figure 2As shown, the cleaning system for cleaning medicine bottles of different sizes includes a waste water pool 1, a plurality of round pipes 2 are vertically arranged in the waste water pool 1, and an annular groove is arranged at the upper end of the round pipe 2. The top of the tube 2 is provided with a fixed disk 10, the bottom of the fixed disk 10 is provided with a ball 6, and the ball 6 is snapped into the annular groove, and the middle part of the fixed disk 10 is provided with a central through hole, and the fixed disk 10 The outside is provided with a first gear 5, and also includes a second gear 7 cooperating with the first gear 5, the second gear 7 is connected with the power output shaft 71 of the motor, and the fixed plate 10 is used to place the medicine bottle 8, The upper end of the fixed plate 10 is recessed downwards to form a groove 101 for fixing the mouth of the medicament bottle 8. The fixed plate 10 is provided with a plurali...

Embodiment 2

[0037] like figure 1 , figure 2 As shown, this embodiment is based on Embodiment 1, and the upper end of the rod body 3 is symmetrically hinged with two semi-circular arc vertical plates, and the two semi-circular arc vertical plates just form a circular tube structure, and the two semi-circular arc vertical plates Connected by a spring, the sponge 4 is made up of 2 semicircle-arc sponge structures, the top of the semicircle-arc sponge structure is provided with a semicircle block, and the semicircle block is in contact with the bottom of the medicine bottle 8, each semicircle The arc sponge structure is correspondingly arranged on the outer wall of a semi-circular arc vertical plate; the second slide plate 96 is provided with an L-shaped fixing piece 92, and one end of the L-shaped fixing piece 92 is hinged on the second slide plate 96, and the other end is connected by a bolt Connect with other L-shaped fixing pieces 92, one side of the L-shaped fixing piece 92 is close to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com