Lifting cable wire sliding device

A cable and sliding wire technology, which is applied in the field of lifting cable sliding wire device, can solve problems such as pulley stuck, hidden safety hazards of operators, safety accidents, etc., and achieve the effect of reducing rolling friction and facilitating dragging of cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

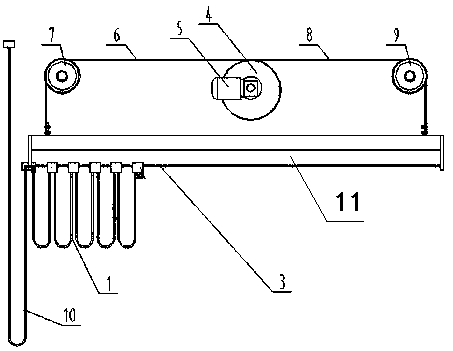

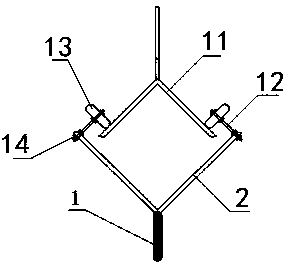

[0013] A lifting cable sliding device of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0014] Such as figure 1 and figure 2 As shown, a lifting cable 1 sliding line device includes a reel 4 with a motor 5, and the reel 4 is respectively connected with a left-pull steel cable 6 and a right-pull steel cable 8, and the left-pull steel cable 6 passes through a left pulley 137 One end of the track 11 is connected, the right pull cable 8 is connected with the other end of the track 11 through the right pulley 139, the guide rail 3 arranged on the V-shaped track 11, the pulley 13 arranged on the guide rail 3, and the pulley 13 is installed through the pulley 13 shaft 12 The shaft is connected to the connecting piece 2, the bottom of the connecting piece 2 is provided with a cable 1, and the cable 1 is connected to the tow cable 10; the angle formed by the V-shaped track 11 is 90°; the pulley 13 shaft 12 is fastened The scr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com