Connecting and fixing method for lining die of high bridge pier roller die

A fixing method and lining mold technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as bolt fixing, and achieve the effects of improving installation speed, ensuring appearance quality, and good link fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

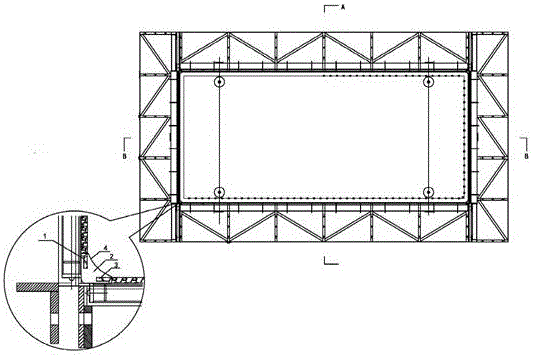

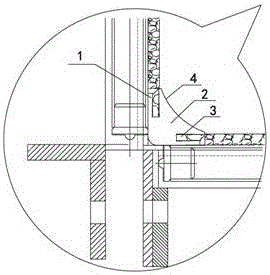

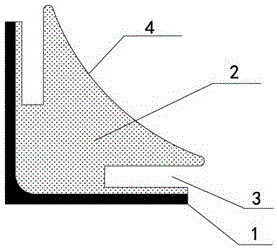

[0014] The chamfering connection and fixing device of the inner lining mold of the high pier roller mold of the present invention is composed of three parts: equilateral angle steel, installation notch, and rubber inner lining.

[0015] The equilateral angle steel 1 is wrapped on the outside of the high-density rubber lining 2, and the high-density rubber lining 2 includes two parts: the rubber installation notch 3 and the inner curved surface 4; when the formwork is assembled, the lining formwork is installed in the rubber installation notch 3 of the fixing device , the equilateral angle steel 1 is located on the outer side and is in direct contact with the axle, and the inner curved surface 4 is located on the innermost side and is in direct contact with the concrete. Fixing holes are arranged on the surface of the equilateral angle steel 1, and the high-density rubber lining 2 is embedded and fixed on the equilateral angle steel 1 through the fixing holes.

[0016] The spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com