Semi-magnetic suspension type vehicle

A magnetic levitation and locomotive technology, applied in motor vehicles, railway vehicles, sliding/floating railway systems, etc., can solve problems such as huge power consumption, and achieve the effects of no operating costs, saving maintenance costs, and simple device structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. However, this embodiment is not intended to limit the present invention, and all similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

[0016] This embodiment selects Shanghai rail transit.

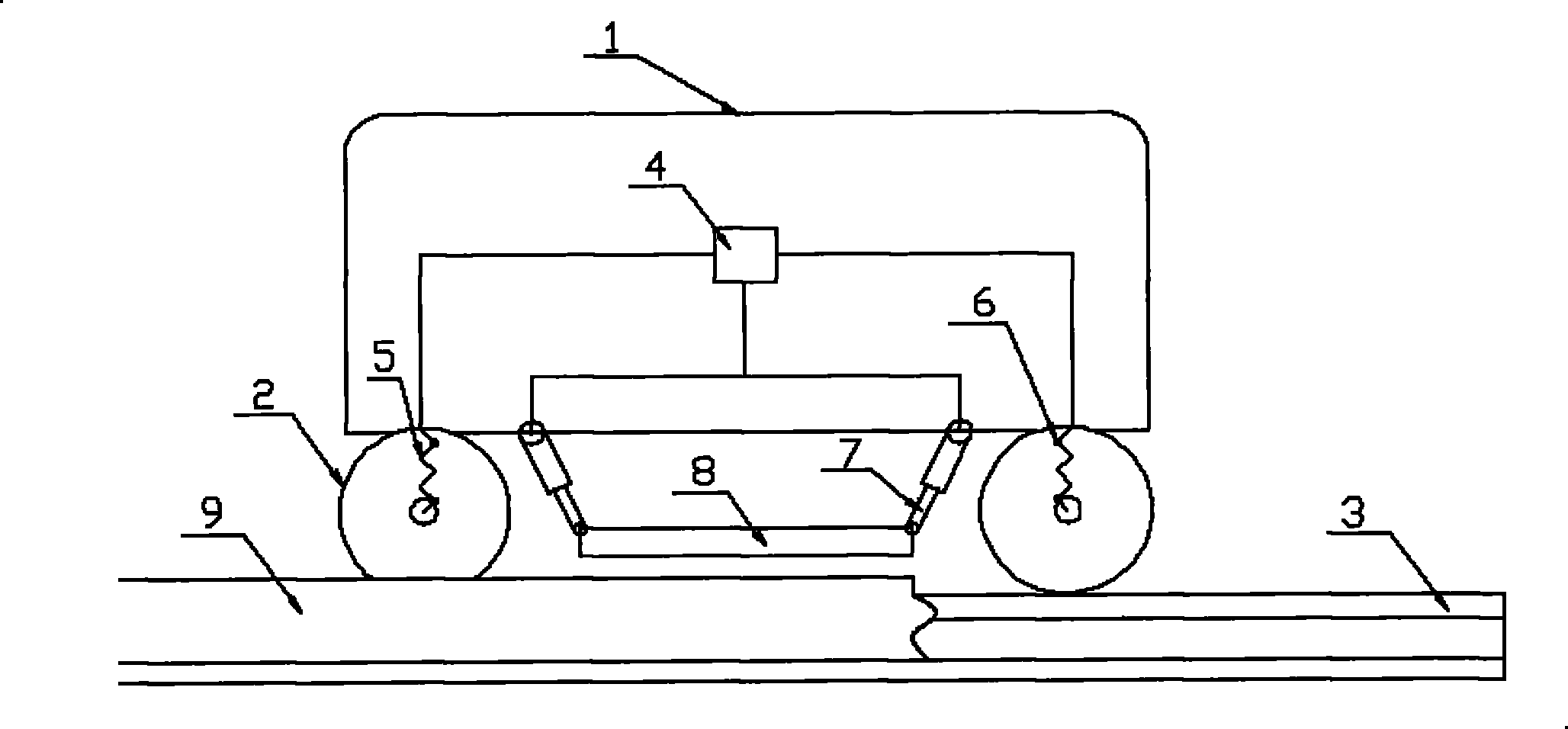

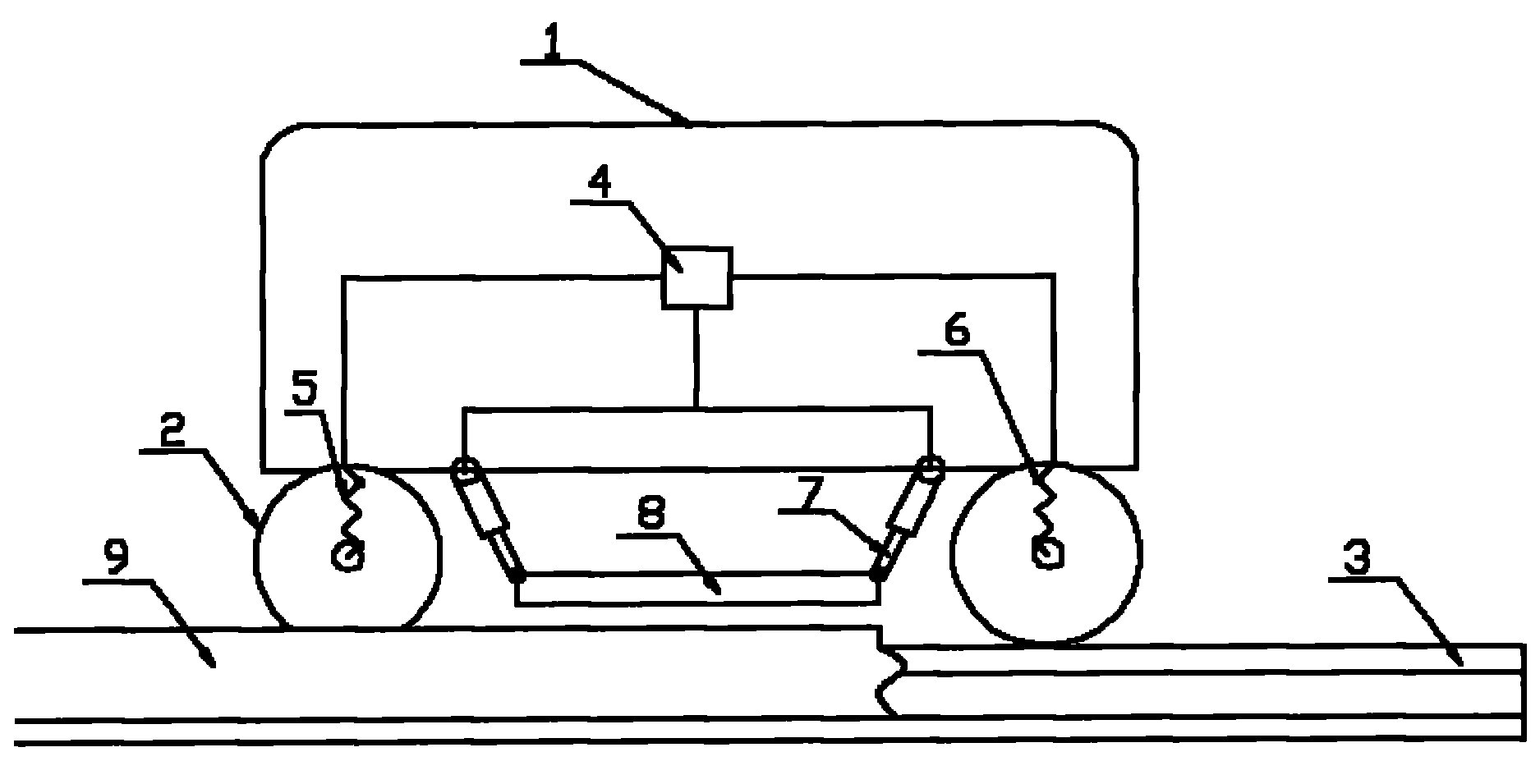

[0017] A semi-maglev locomotive, such as figure 1 As shown: the wheel 2 of the car body 1 is connected with the track 3, the car body 1 is connected with an industrial computer 4, the wheel 2 is connected with a wheel spring 5, and the wheel spring 5 is connected with a stress sensor 6. The industrial computer 4 passes through four The road stress sensor lines are respectively connected to the stress sensors 6 provided on each wheel spring 5, the car body chassis is provided with a lifting device 7, the upper part of the lifting device 7 is connected to the industrial computer 4 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com