Patents

Literature

49results about How to "Low rolling friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

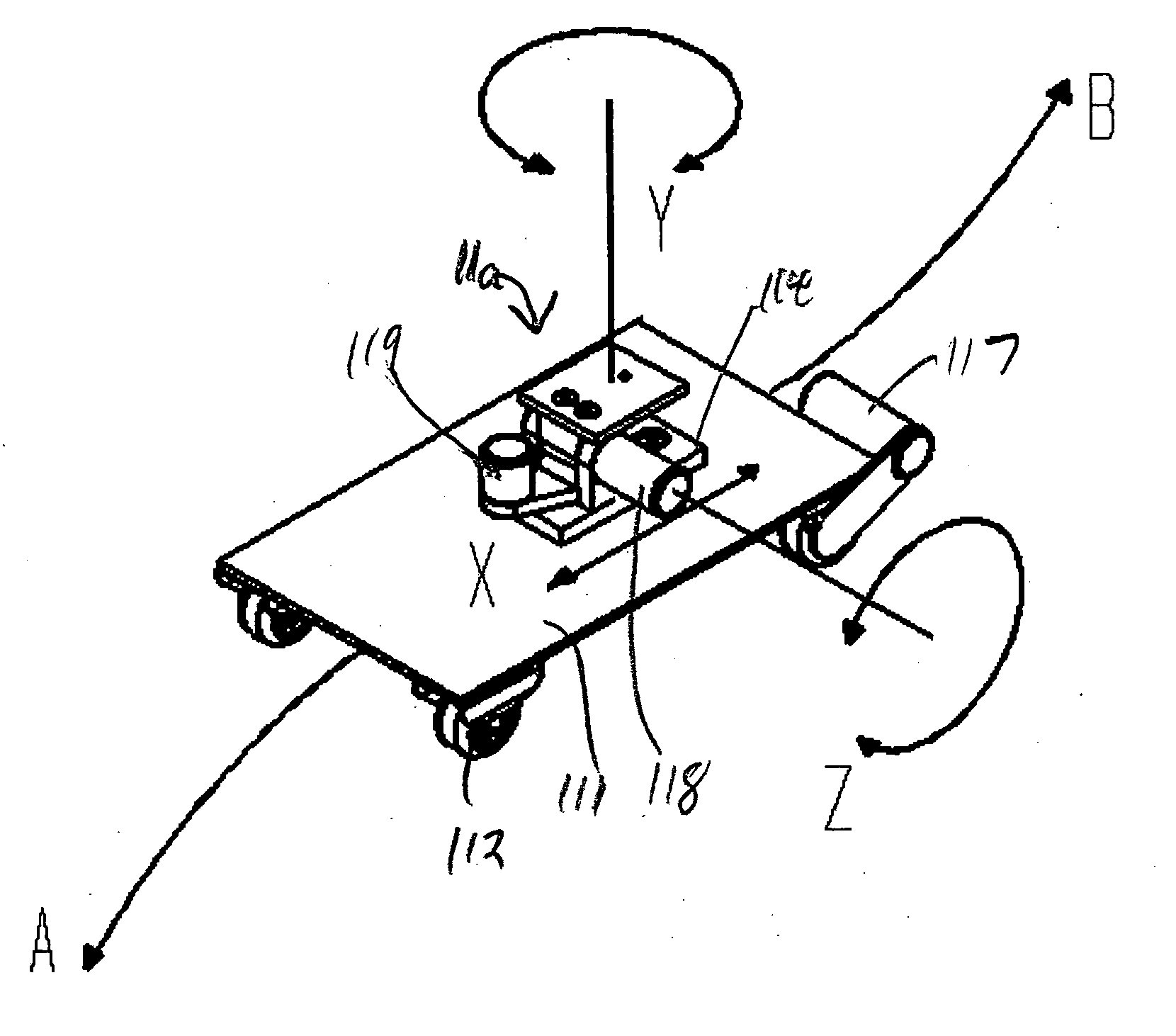

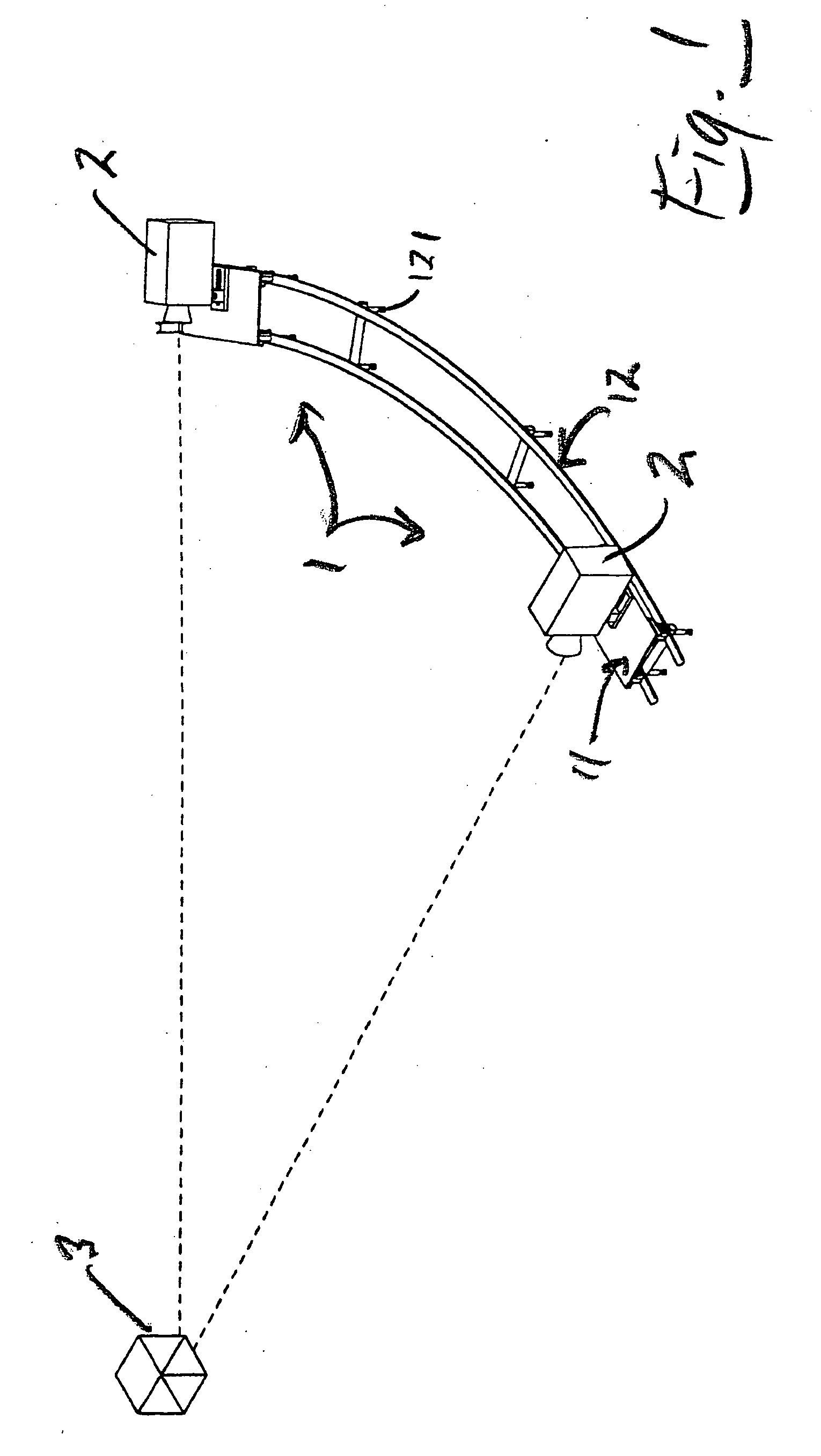

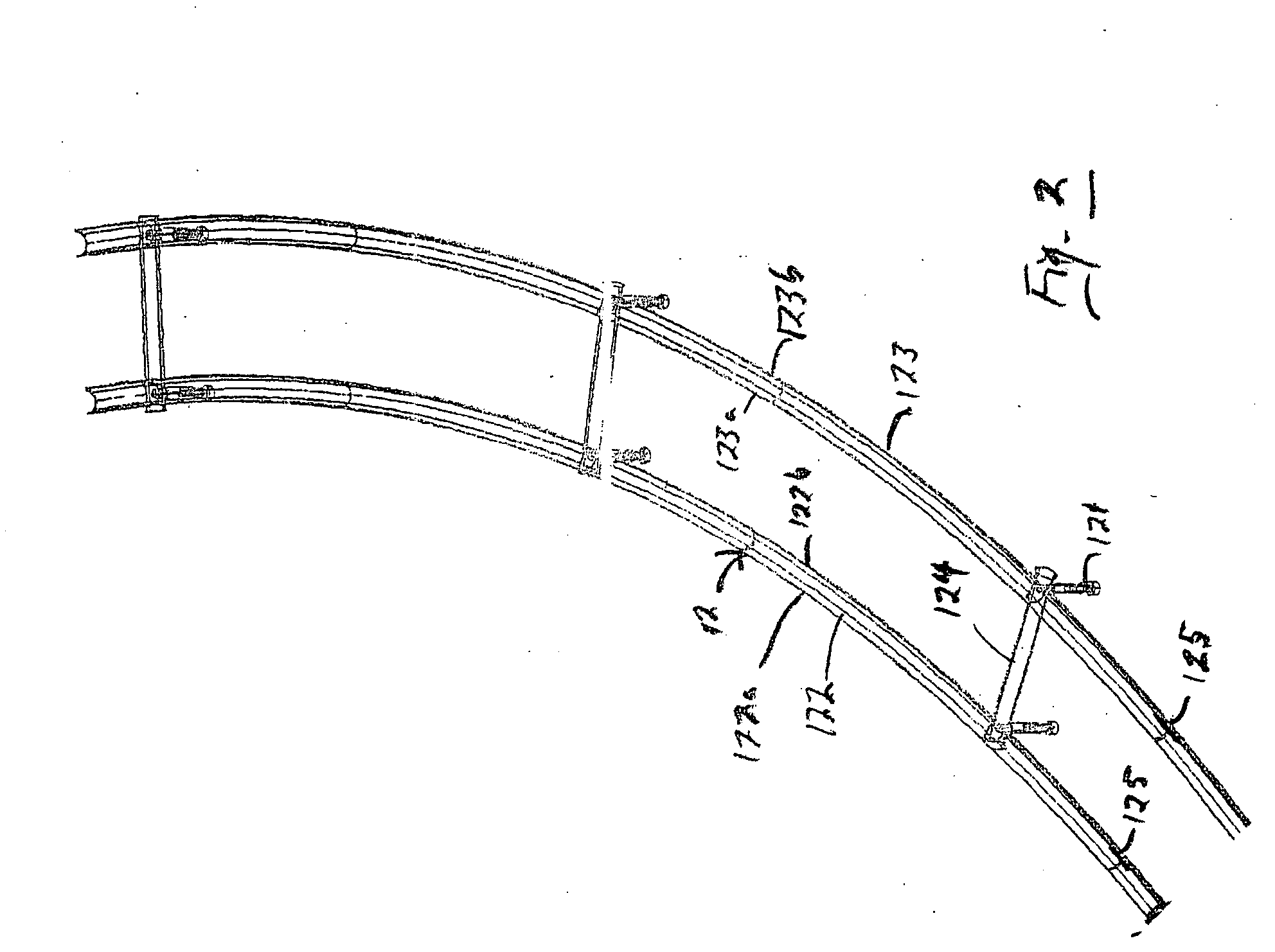

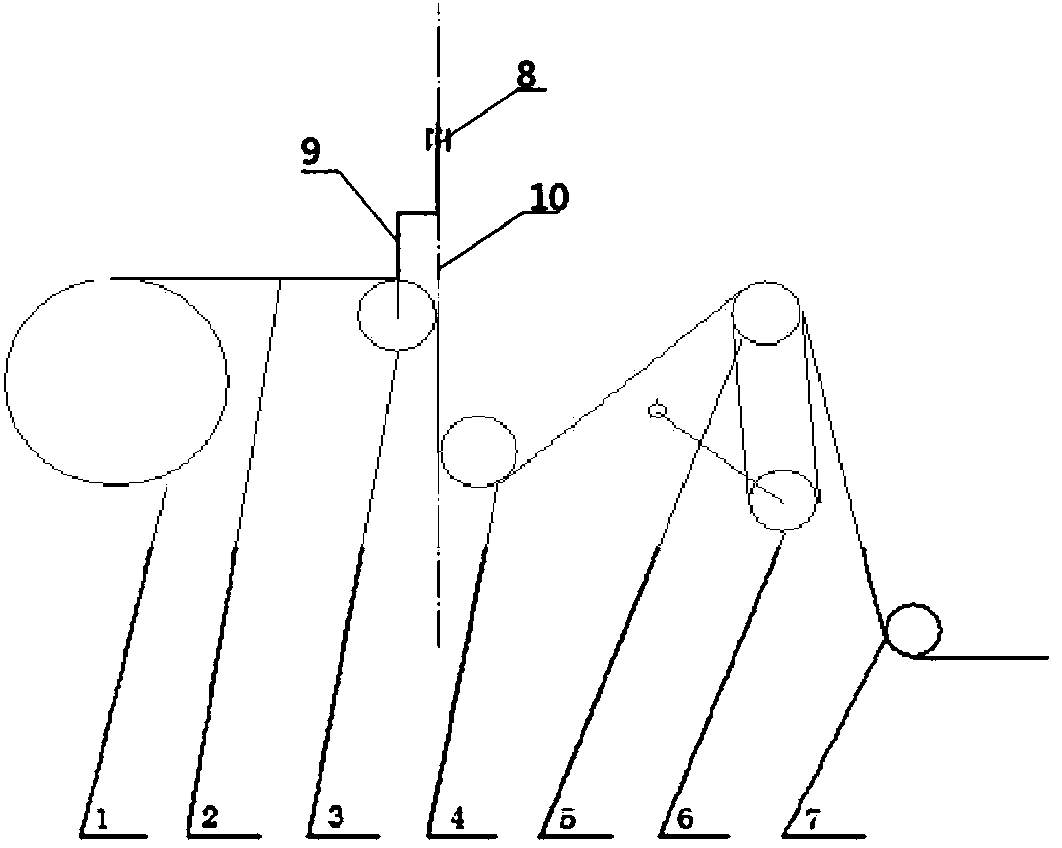

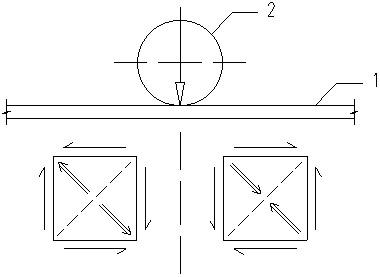

Economical camera-support-and-movement track-and-dolly system providing high stability and precision to camera movement

InactiveUS20050231689A1Cheap constructionEasy to useProjectorsStands/trestlesEngineeringAngular orientation

A system for moving a camera in space has a track with two spaced-parallel rails, each rail having two upward-extending spaced-parallel lips, and a dolly holding the camera and riding upon both rails of the track. The track is preferably segmented with each elongate rail segment preferably in the cross-section of half of a tube, while the dolly has wheels that contact only, and that ride upon, the upward-extending spaced-parallel lips of each half-tubular rail. The camera is mounted close upon the support platform of the generally rectangular wheeled dolly, which is itself squat and low to the track's two spaced-parallel rails. According to the geometries of construction, the camera is relatively insensitive in space and in angular orientation to such irregularities in track and moving dolly as are in any case minor by design, and the camera can be moved along complex paths with great precision for purposes of motion pictures and movies.

Owner:LONGLEY BRIAN

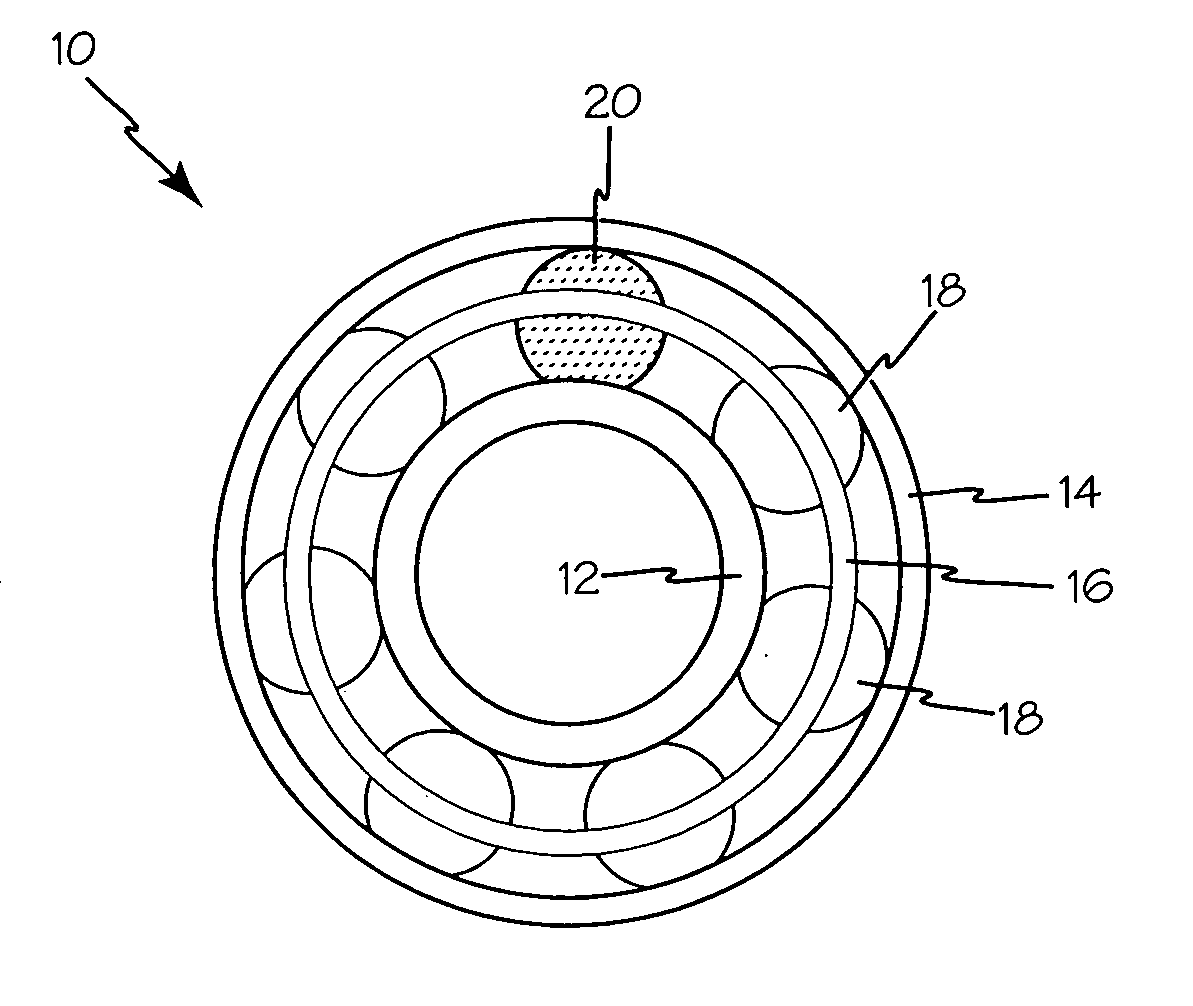

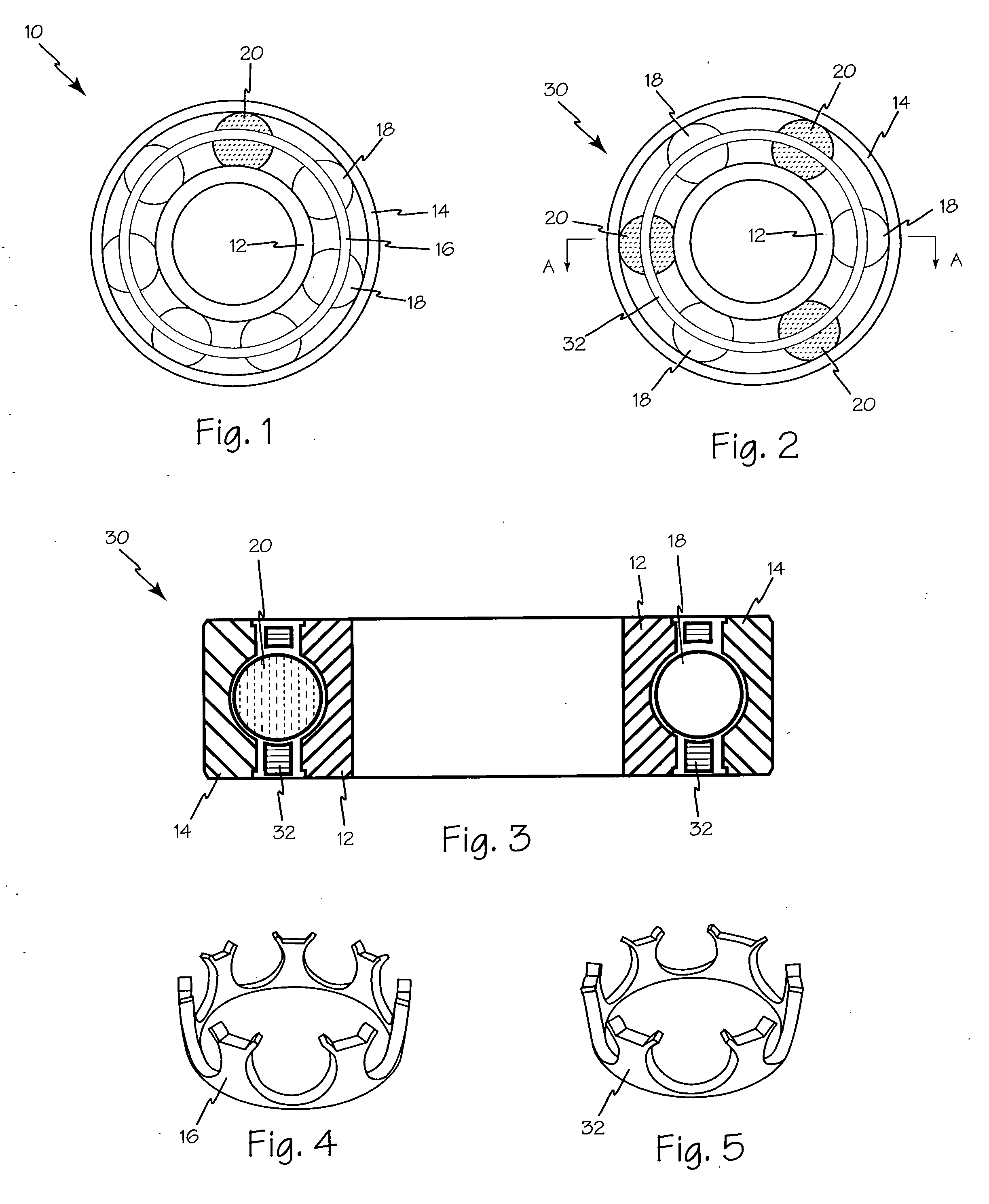

Hybrid skate bearing

InactiveUS20060182376A1Low costLow rolling frictionRolling contact bearingsBearing componentsBall bearingMetallurgy

A hybrid roller bearing according to the present disclosure combines at least one ceramic ball bearing and steel ball bearings to form a complete roller bearing. The use of less than a complete set of ceramic balls in a single bearing may offer many of the benefits of a full ceramic bearing at a lower cost. Ceramic ball bearings provide lower rolling friction than steel balls and generally remain cleaner and require less lubrication.

Owner:BURWELL SCOTT

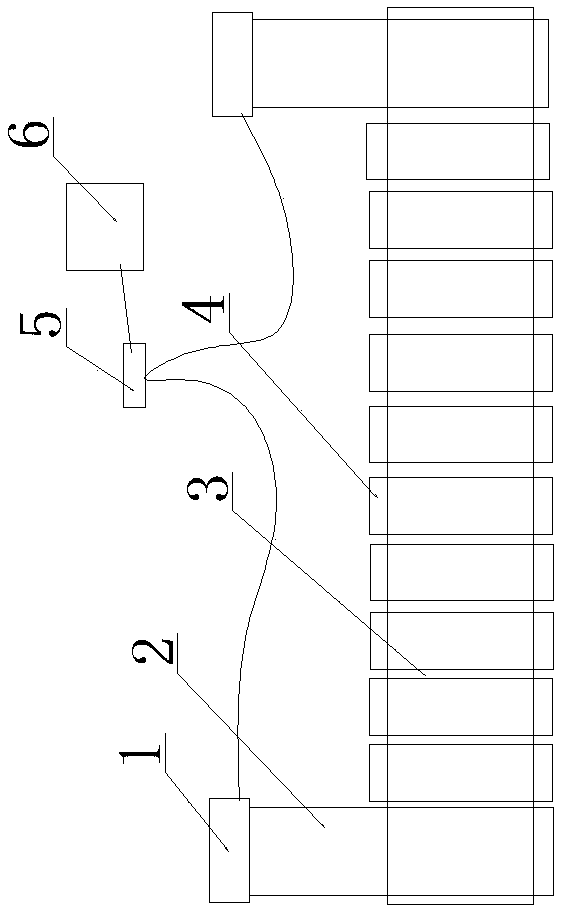

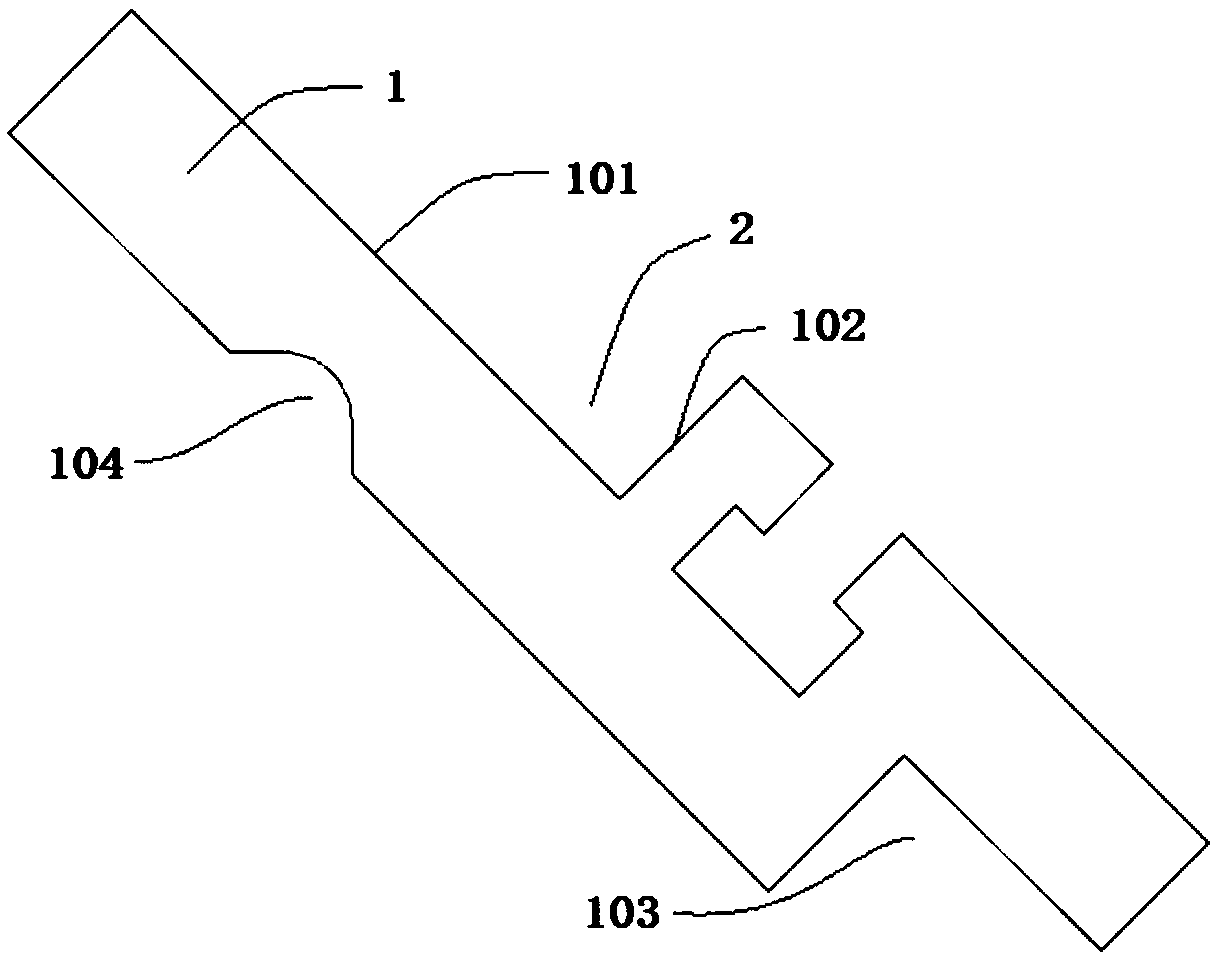

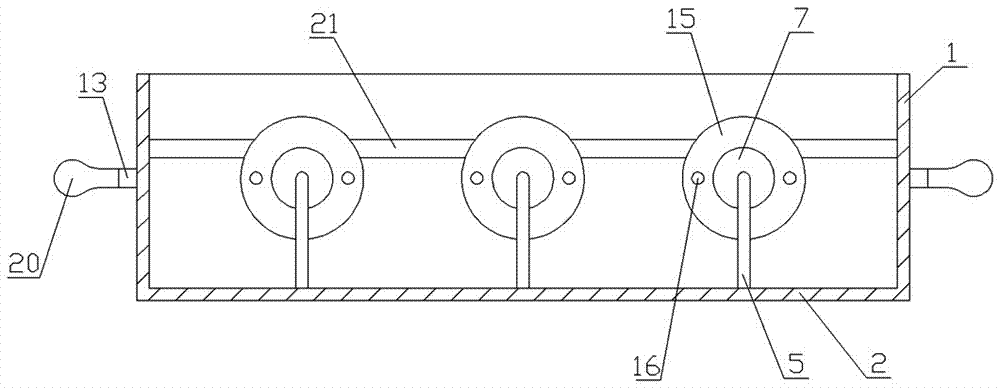

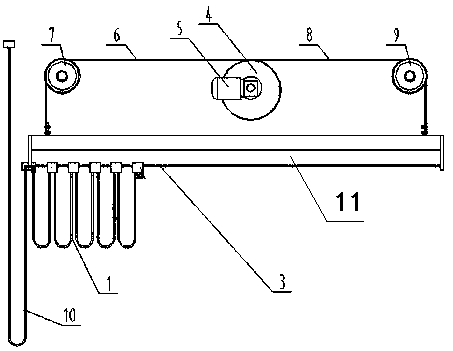

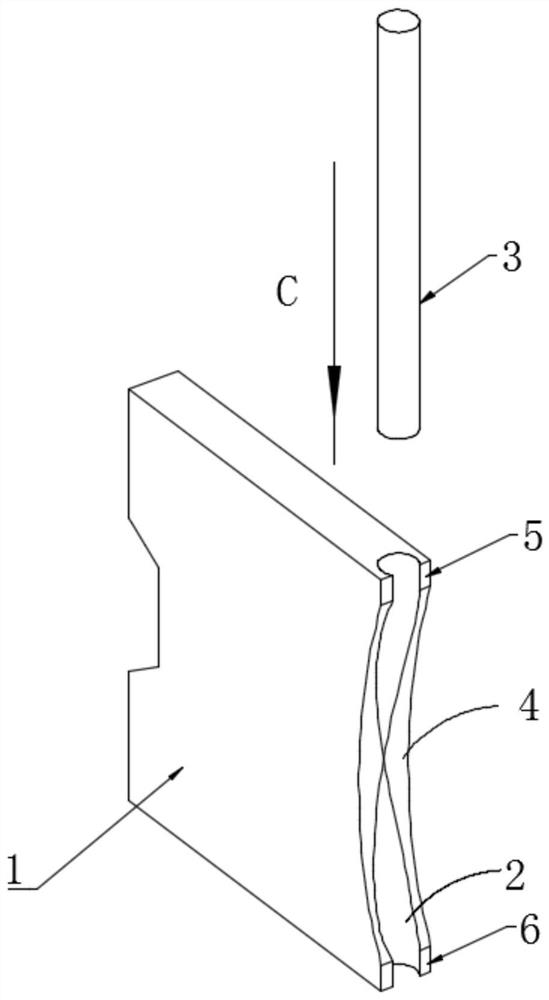

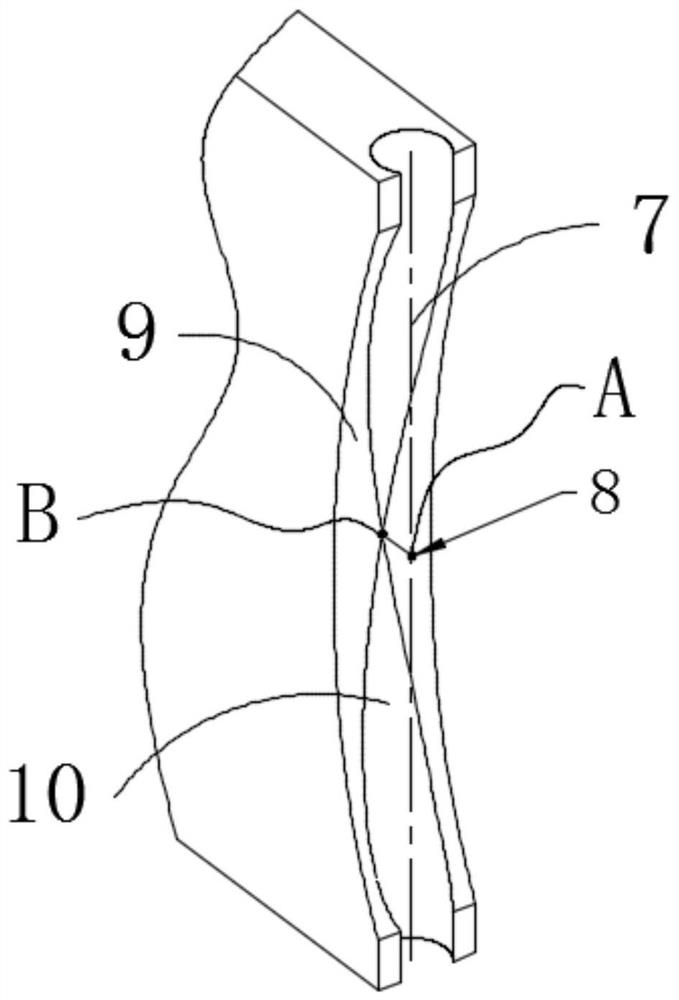

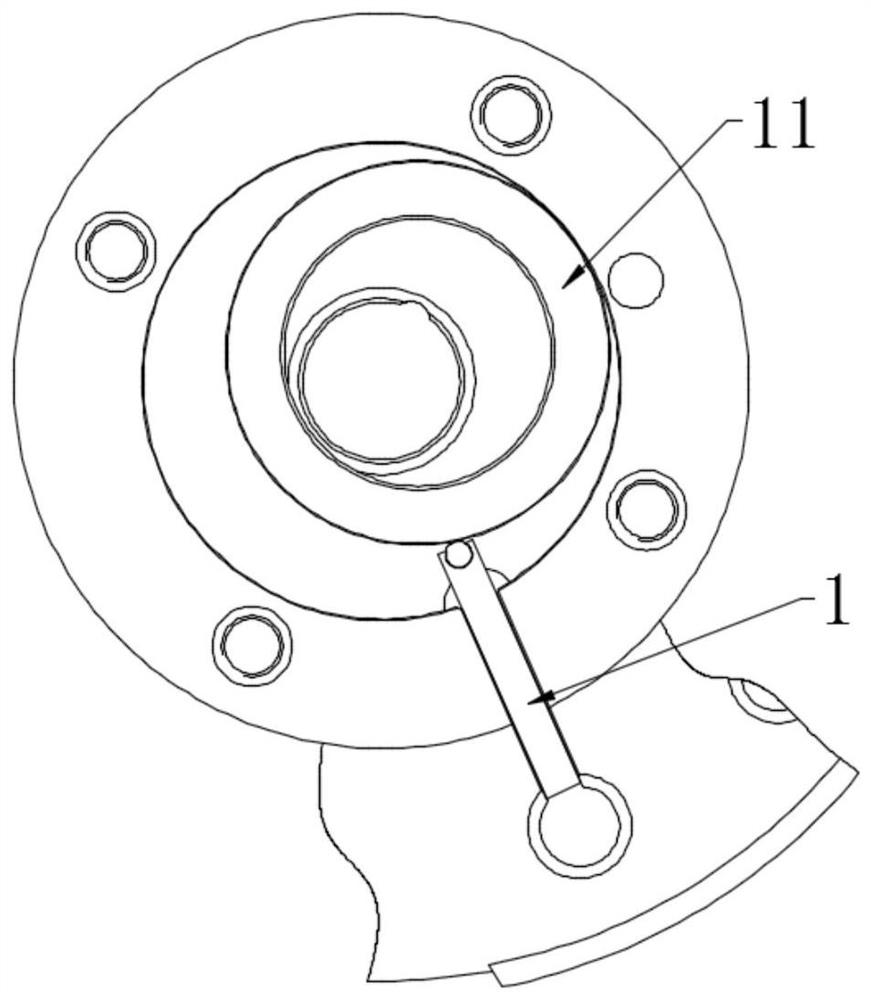

Substation secondary wire straightening and bending device and wire fixing tightness commissioning method

ActiveCN104348097AEasy to removeEasy to bendApparatus for overhead lines/cablesSwitchgearEngineeringMagnet

The invention discloses a substation secondary wire straightening and bending device and a wire fixing tightness commissioning method. The device comprises a cylinder, wherein supporting legs which are movably connected are arranged at the two ends of the cylinder and a magnet is arranged at one end of each supporting leg. Not only can substation secondary wires be straightened and bent in a batch, but also automatic bending can be realized, the bending tidiness and efficiency are high, the maintenance of a protection screen in future is facilitated, and more importantly, whether the substation secondary wires are firm or not can be conveniently detected.

Owner:NANYANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

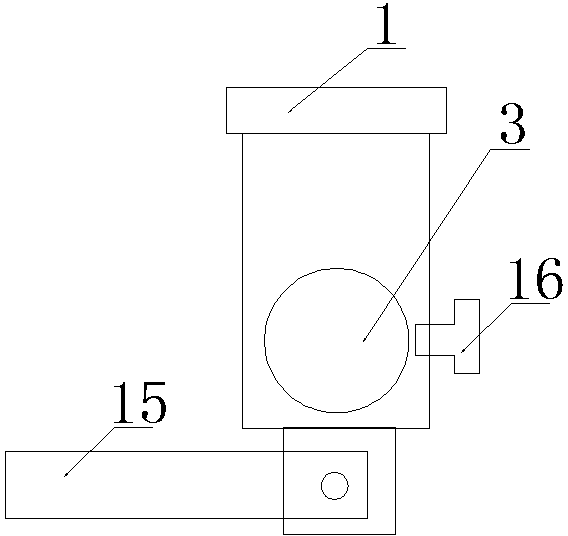

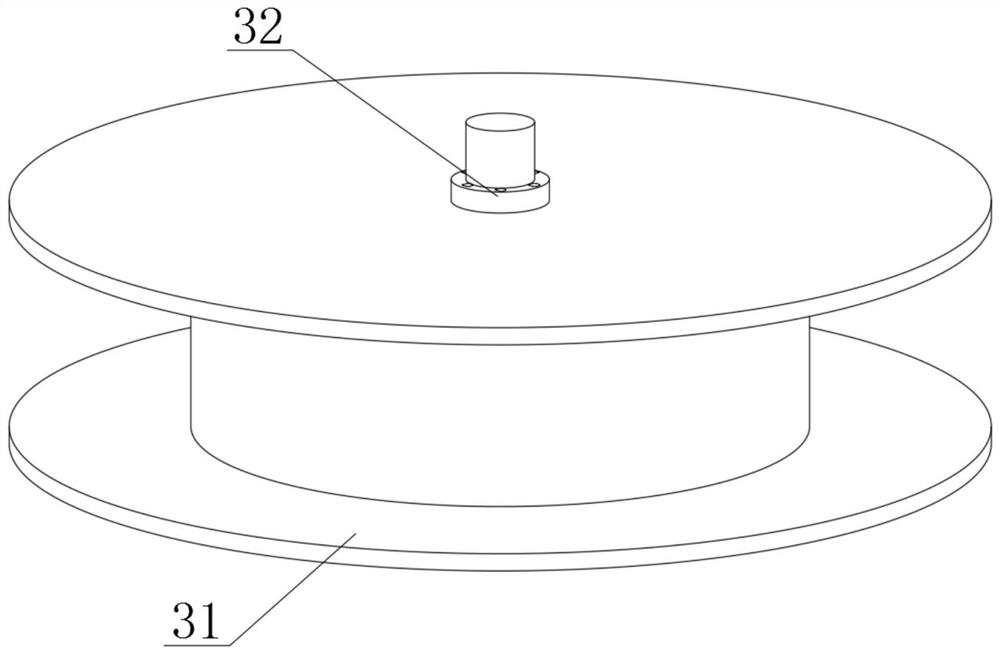

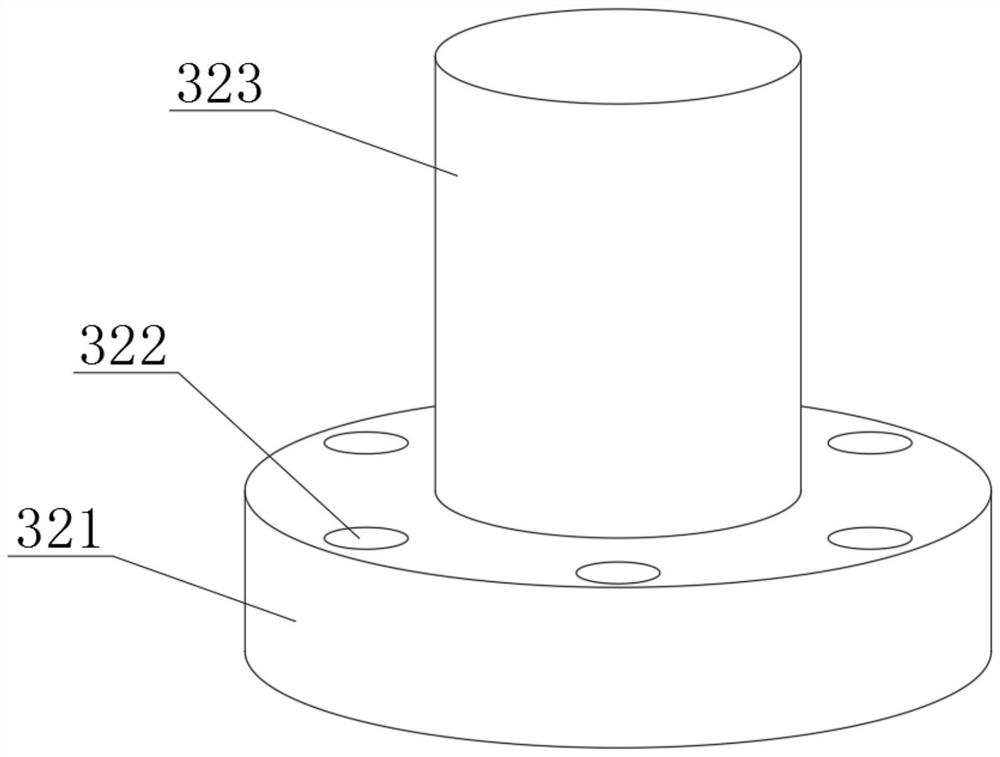

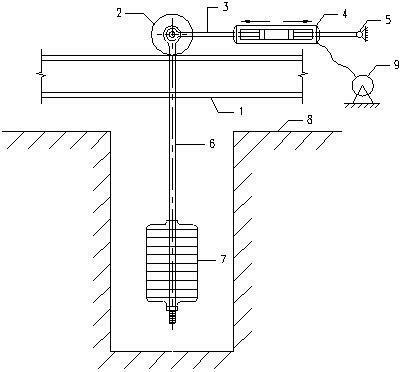

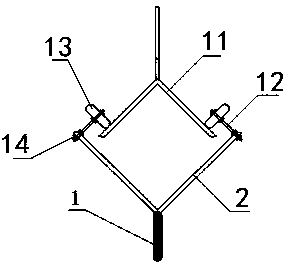

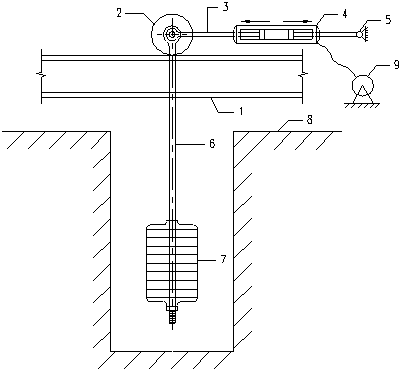

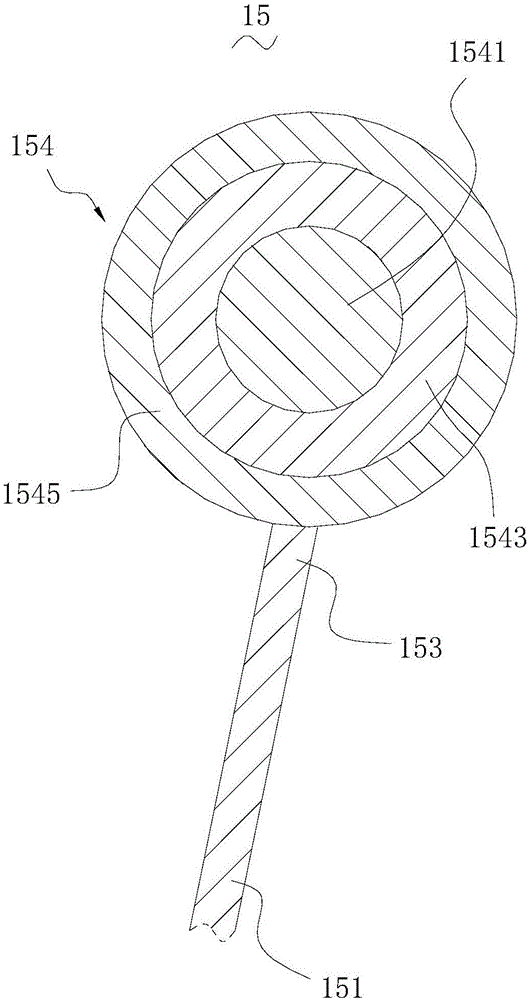

Optical fiber pay-off device

The invention provides an optical fiber pay-off device which is used in the secondary coating procedure in optical fiber production. According to the technical scheme, an optical fiber is paid off from an optical fiber pay-off disc and guided by a universal wheel, a positioning wheel and a positioning wheel set, undergoes speed regulation conducted by a dancing wheel set and finally enters a sleeve. The universal wheel is supported by a rotatable support provided with a bearing. A universal wheel support rotating shaft center line is kept tangent to a wheel groove inner circle of the universal wheel and a wheel groove inner circle of the positioning wheel at the same time. Therefore, sliding friction force in the whole optical fiber walking route is greatly reduced, only small rolling friction force exists, and the quality of the optical fiber in the sleeve is ensured.

Owner:TIANJIN YOFC XMKJ OPTICAL CABLE

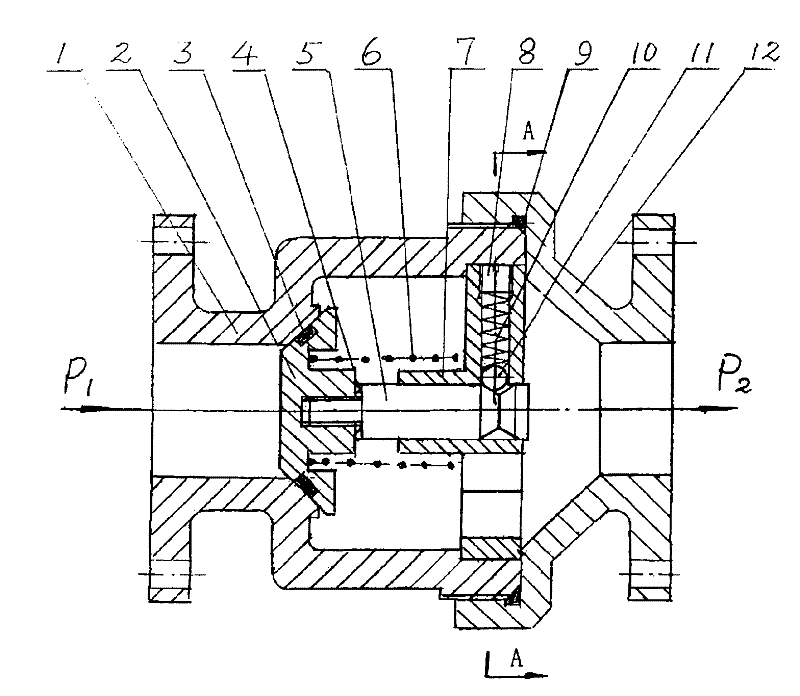

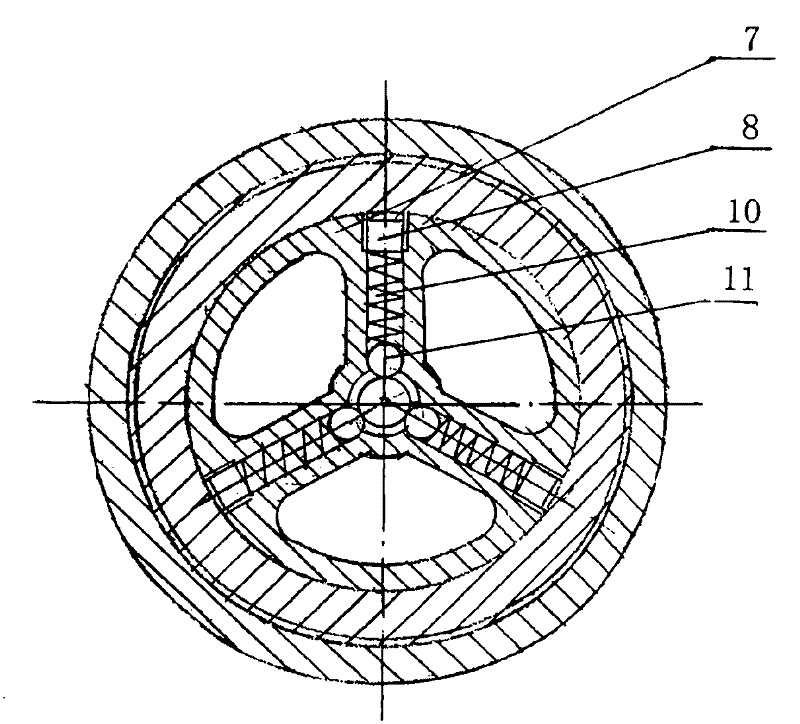

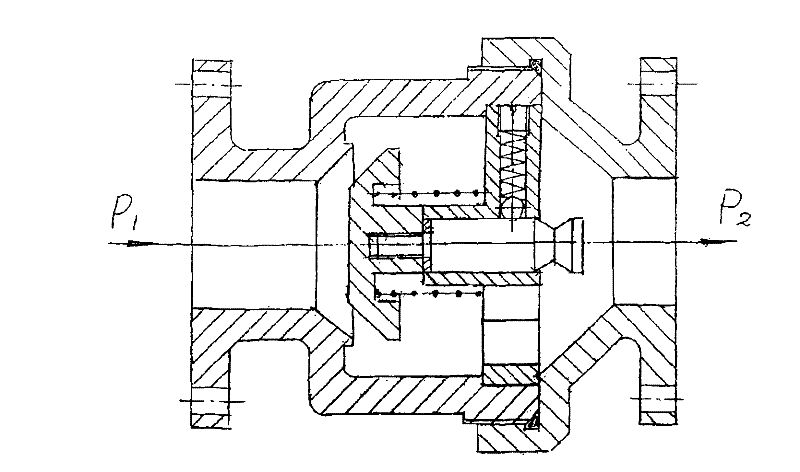

Low-resistance non-return valve

InactiveCN102563136ANo change in sealing abilityLow flow resistanceOperating means/releasing devices for valvesCheck valvesEngineeringSteel ball

The invention relates to a low-resistance non-return valve. The low-resistance non-return valve is characterized by being provided with a valve body and a valve cover connected with the valve body, wherein a check valve is arranged in a cavity formed by the valve body and the valve cover; the end parts of the valve body and the valve cover have a water inlet and a water outlet respectively; the central lines of the water inlet and the water outlet are consistent with the central line of the check valve; the check valve comprises a valve seat, a valve core matched with the valve seat, a valve rod connected to the valve core and a guide sleeve which is in sliding fit with the valve rod; a spring I is arranged between the guide sleeve and the valve core; a radial triangular groove is formed at the downstream end of the valve rod; the guide sleeve consists of an inner ring and an outer ring; the inner ring is connected with the outer ring through connecting ribs; a through hole is drilled in the center of each connecting rib; a steel ball, a spring II and an adjustment screw are arranged in the through hole in sequence; and the steel ball acts on an inclined surface on the left side of the triangular groove of the valve rod under the condition that the valve core is closed. The low-resistance non-return valve is low in energy consumption, and the sealing performance is not influenced.

Owner:HANGZHOU CHUNJIANG VALVE

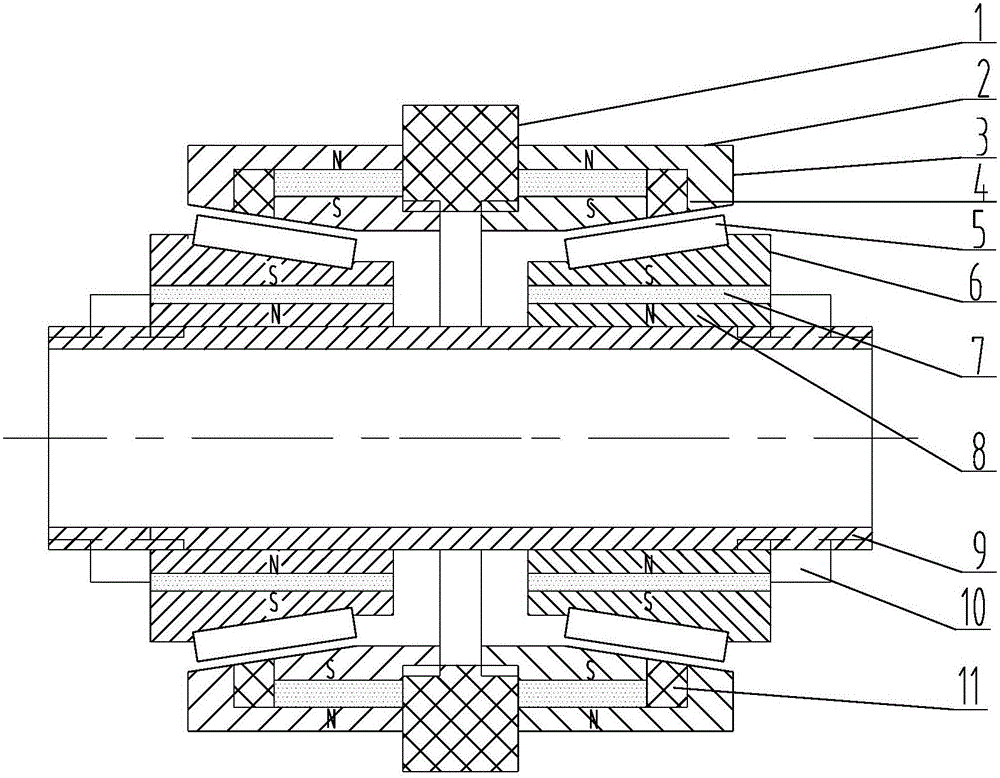

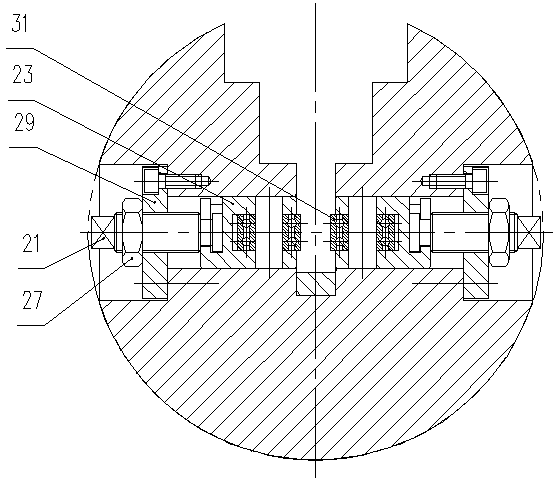

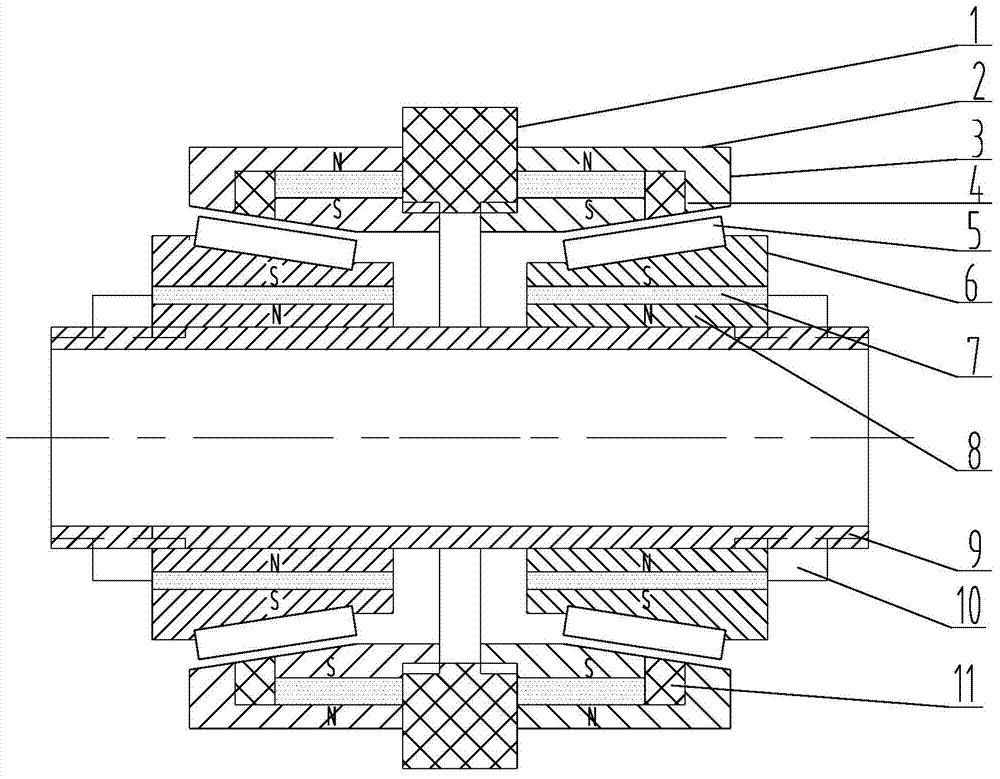

Permanent magnetic levitation auxiliary bearing

The invention relates to a permanent magnetic levitation auxiliary bearing which comprises two inner magnetic groups and two outer magnetic groups which are symmetrically and oppositely arranged on a shaft sleeve. Each inner magnetic group is composed of an annular inner magnetic solid boot, an inner magnetic ring, a wedge-shaped inner magnetic solid boot and a cylindrical roller which are sequentially arranged from inside to outside in the radial direction. The outer magnetic groups are fixed to the outer sides of the inner magnetic groups through special metal rings in the radial direction. Each outer magnetic group is composed of a wedge-shaped outer solid boot, an outer magnetic body and an annular outer magnetic solid boot which are sequentially arranged from inside to outside in the radial direction. An annular gap is reserved between each wedge-shaped outer magnetic solid boot and the corresponding cylindrical roller. The radial magnetization direction of the inner magnetic rings is opposite to that of the outer magnetic rings. The permanent magnetic levitation auxiliary bearing is in a magnetic levitation state when lightly loaded and has no mechanical friction. On the condition of heavy load, the outer magnetic groups and the inner magnetic groups are in rolling connection with the cylindrical rollers, and the bearing still has the high convolution precision and high bearing strength; in addition, due to the repelling force of the magnetic effect, the pressure of the cylindrical rollers on the wedge-shaped outer magnetic solid boots is greatly reduced, and rolling friction force between the cylindrical rollers and the wedge-shaped outer magnetic solid boots is greatly reduced.

Owner:ANSHAN GANGFENG FAN

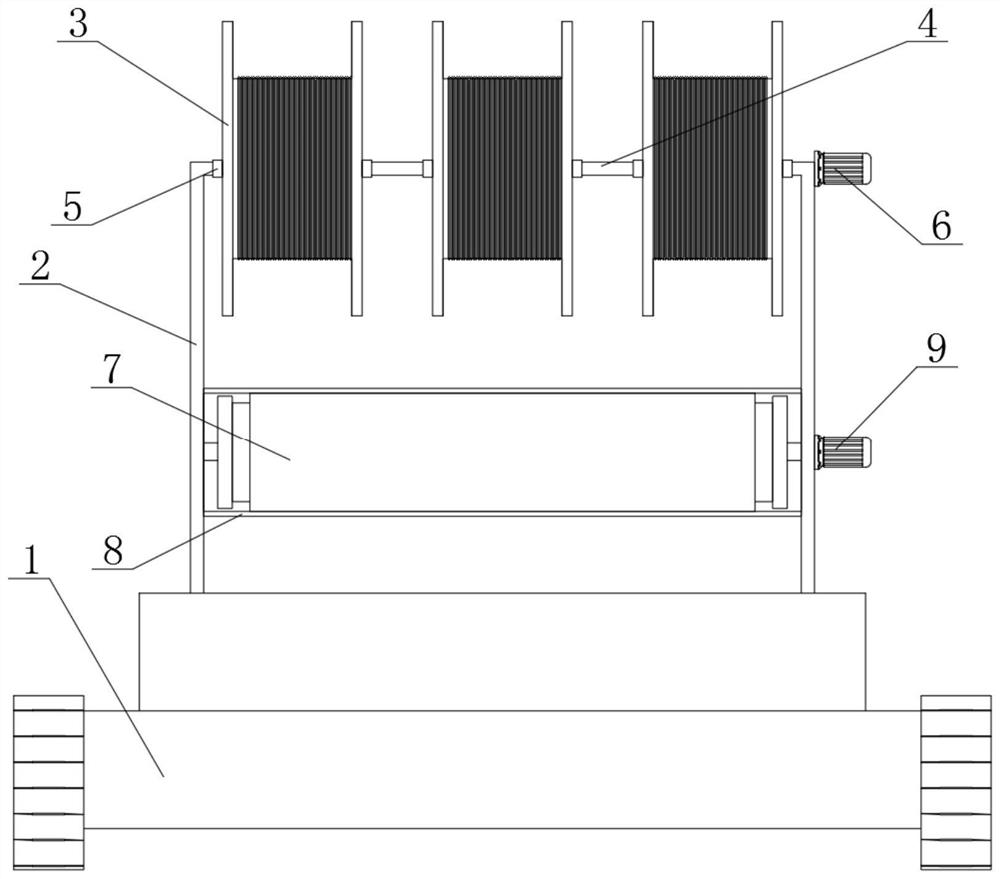

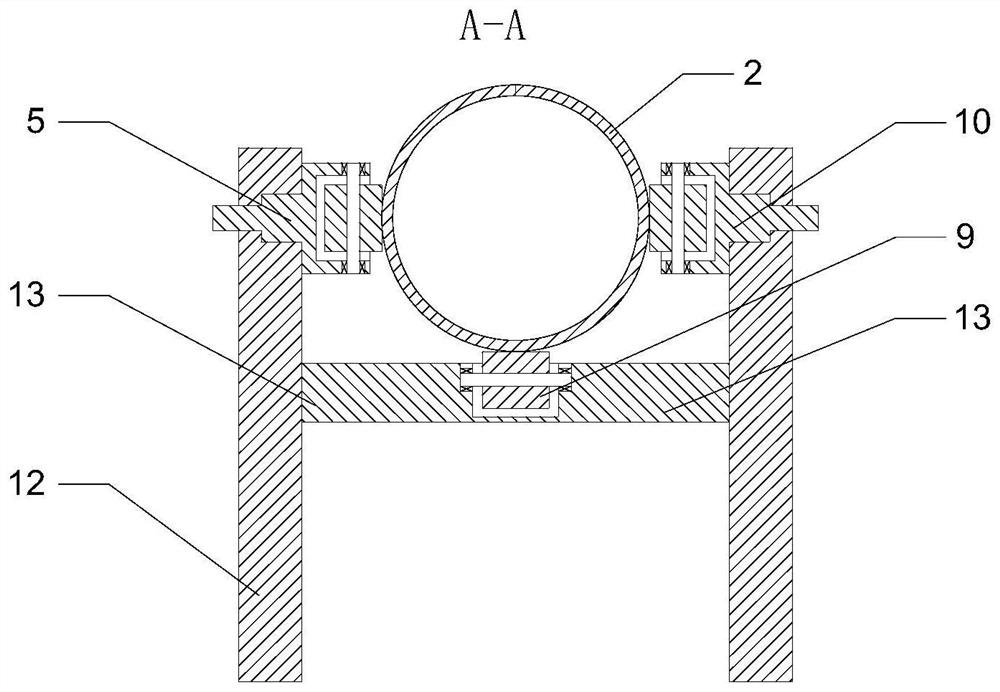

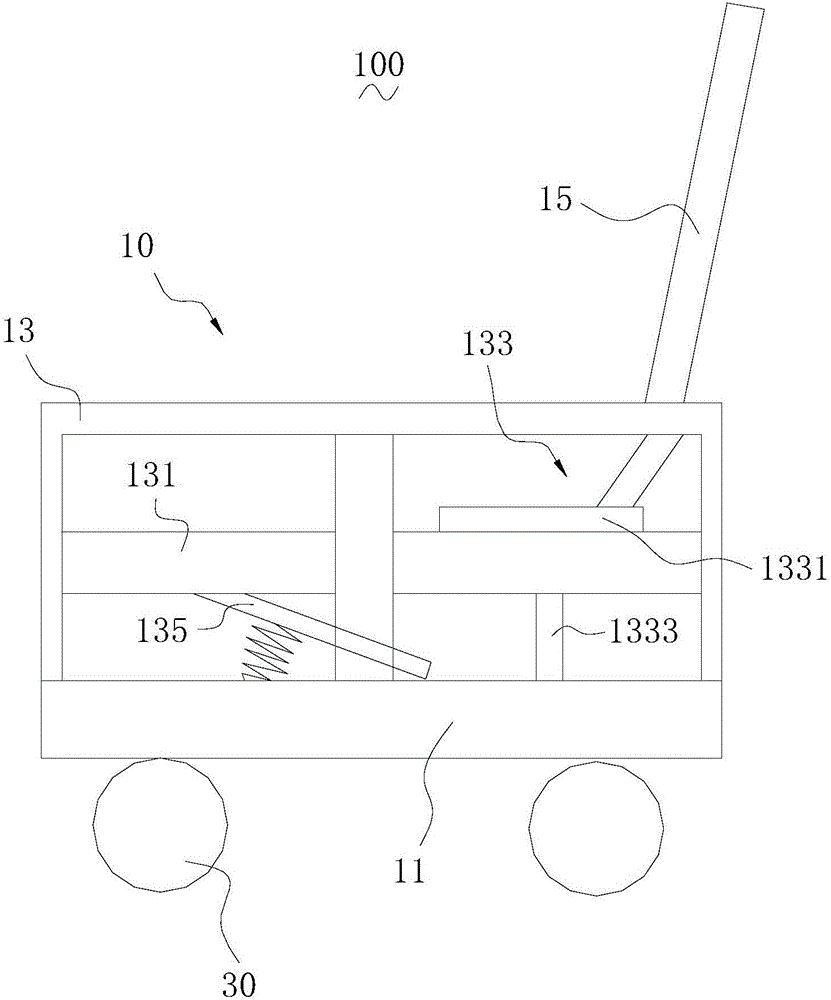

All-terrain bypass cable automatic laying vehicle

ActiveCN111884132AFast releaseEasy to operateApparatus for laying cablesWebs handlingRemote controlElectric cables

The invention discloses an all-terrain bypass cable automatic laying vehicle, and particularly relates to the field of cable laying. The vehicle comprises a driving vehicle, two supporting frames arefixedly arranged at the top of the driving vehicle, three cable take-up reels are arranged at the top ends of the supporting frames, and a connecting column is arranged between every two adjacent cable take-up reels;fixing pieces are arranged between the connecting column and the cable take-up reel and between the supporting frame and the cable take-up reel. The vehicle is controlled to run and the cable take-up reel is controlled to unwind and wind cables and moisture-proof cloth in a wireless remote control mode, three bundles of cables are loaded on the cable take-up reel on the running vehicle, each bundle of cable bundles can be easily disassembled and replaced, and the cable bundles are installed on the running vehicle and can be driven by the first servo motor to adjust the releasespeed; therefore, the rotation number of the cable take-up reel is adjusted according to laying requirements, the cable release speed is increased, manpower output can be reduced, three-phase circuitlaying can be conducted through single-pass work, operation of constructors is facilitated, the crawler wheels are used for bypass operation without power failure, and it is guaranteed that the traveling vehicle adapts to laying of various terrains.

Owner:广州德晟电力科技有限公司

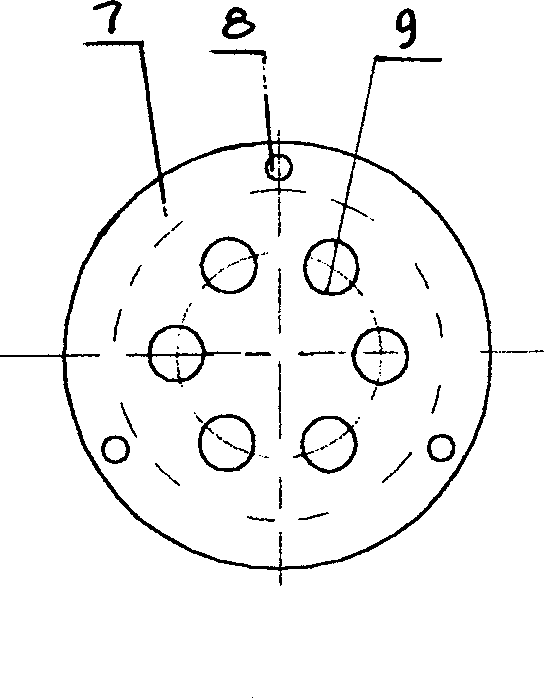

Photoelectric 12 divisions drilling tools face angle drill following sensor

The present invention is one photoelectronic 12-graduation drilling rig face angle sensor. The drilling rig face angle sensor consists of front cover plate; 6 infrared LEDs set separately inside 6 LED holes distributed homogeneously in circumference of the front cover plate; and holding bin with light blocking device and 6 holes holding 6 infrared receiving tubes separately; with the LEDs and the infrared receiving tubes are coaxial separately. The present invention has the features of test with the drilling rig, high vibration resistance, small size and low cost.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

False twister with function of adjusting thread tension

Owner:新昌县城关升华机械厂

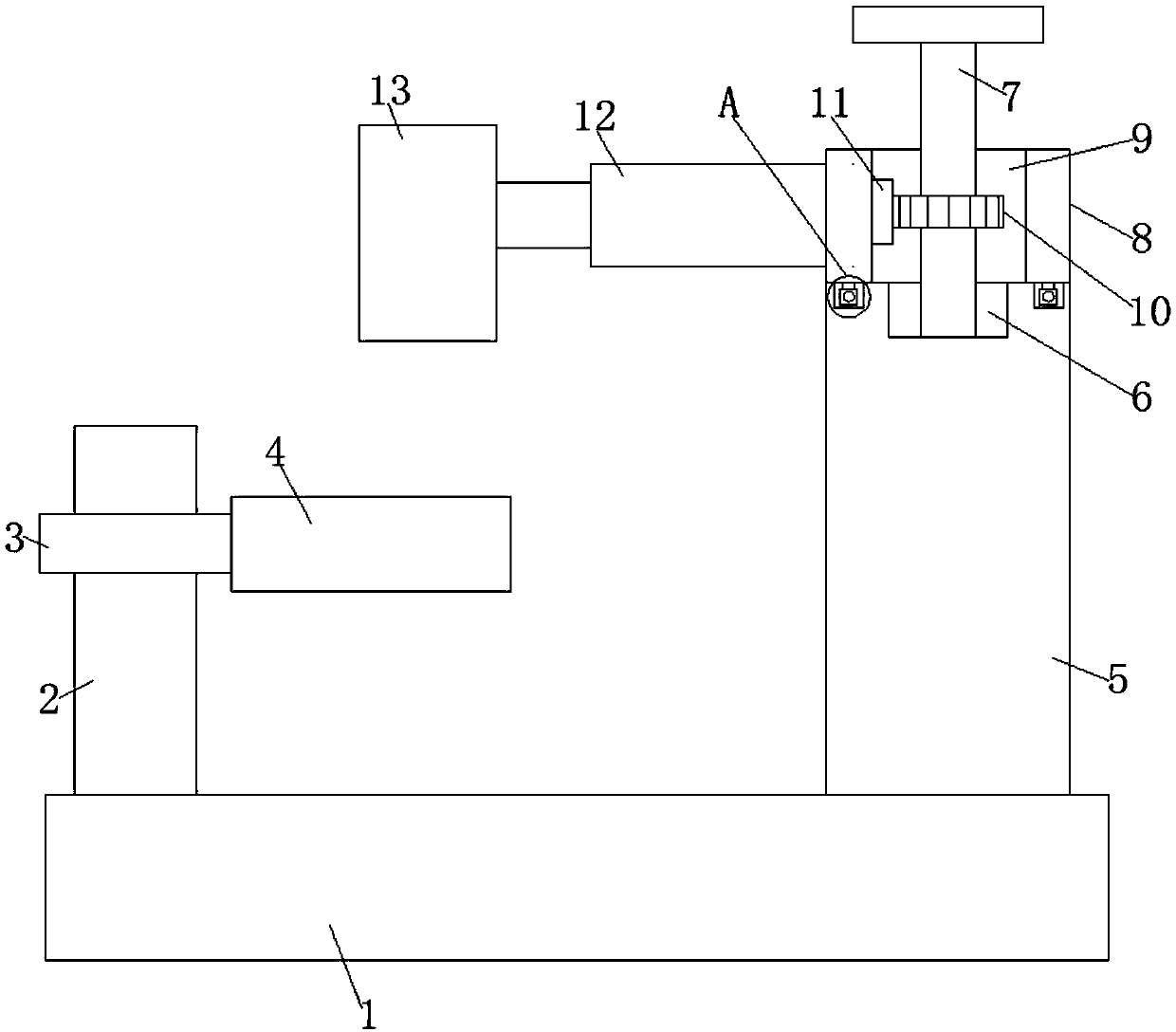

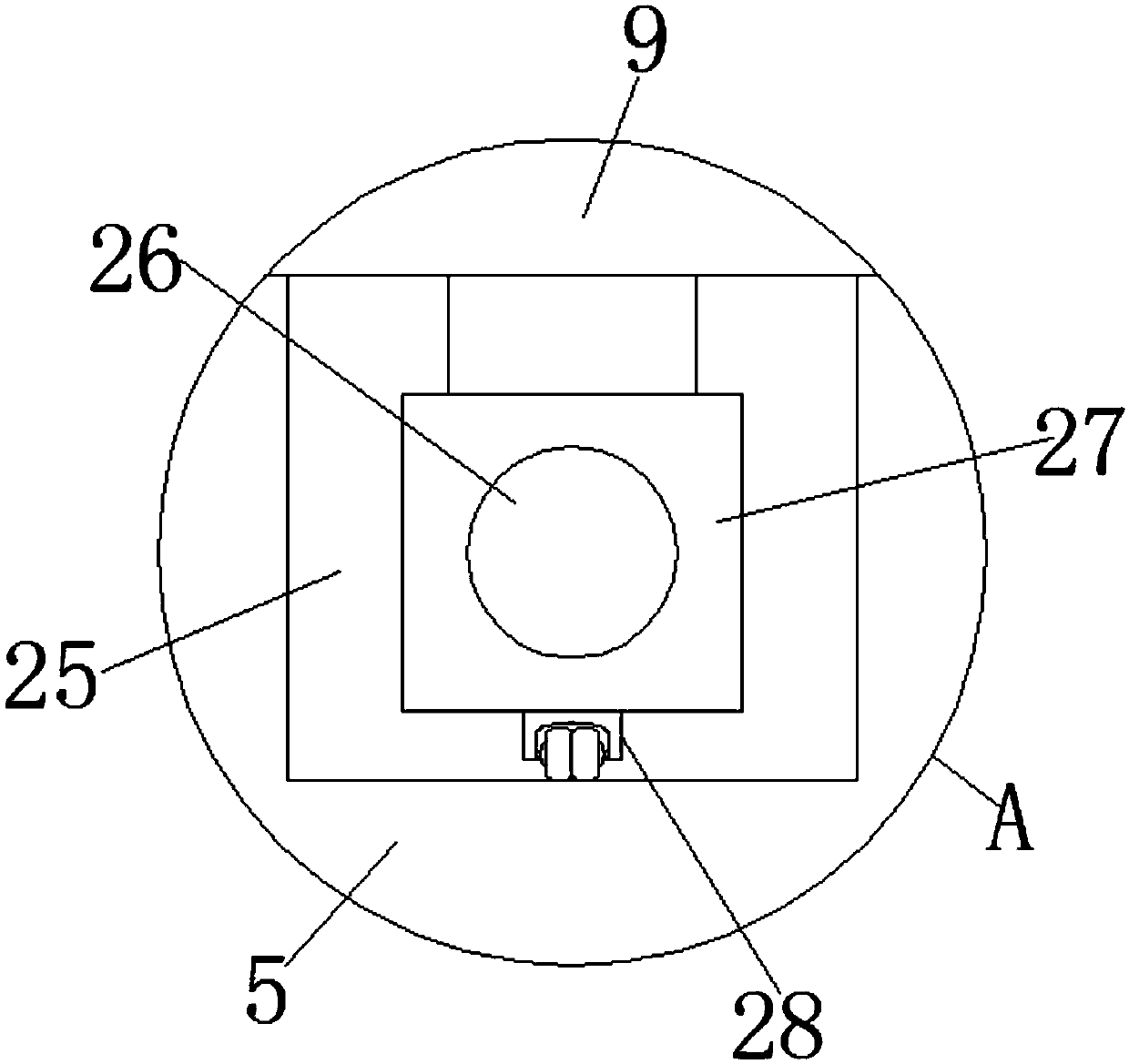

Dedicated clamp for processing upper die and processing method

PendingCN109333112AHigh positioning accuracyRealize continuous adjustmentPositioning apparatusMetal-working holdersEdge surfaceEngineering

The invention discloses a dedicated clamp for processing an upper die and a processing method, and belongs to the field of die steel processing devices. The dedicated clamp comprises a die holder, a lower supporting piece, an upper adjusting piece and an angle adjusting mechanism; the die holder is provided with a clamping position where the upper die is arranged; the lower supporting piece and the upper adjusting piece are movably connected with the two ends of the die holder; the angle adjusting mechanism is connected with the upper adjusting piece; the die holder can be driven to rotate with the lower supporting piece as a supporting point through the upper adjusting piece, so that the angle of an upper die cutting edge surface is adjusted, and the upper die cutting edge surface is arranged at the horizontal processing position; and the distance between the lower supporting piece and a standard supporting surface is determined by a digital model, that is, the rotating angle of the die holder is determined, and the distance is finely adjusted through the combination with a pair of wedge blocks of which the inclined surfaces are matched so as to mill the upper die cutting edge surface with small angle change. The structure of the milling machine can be not replaced, the upper die cutting edge surface of different angles can be milled, high positioning precision of the upper die cutting edge surface is ensured, and the supporting stability of the clamp is high.

Owner:ANHUI LIYUAN NUMERICAL CONTROL CUTTING TOOL & PATTERNS MFG

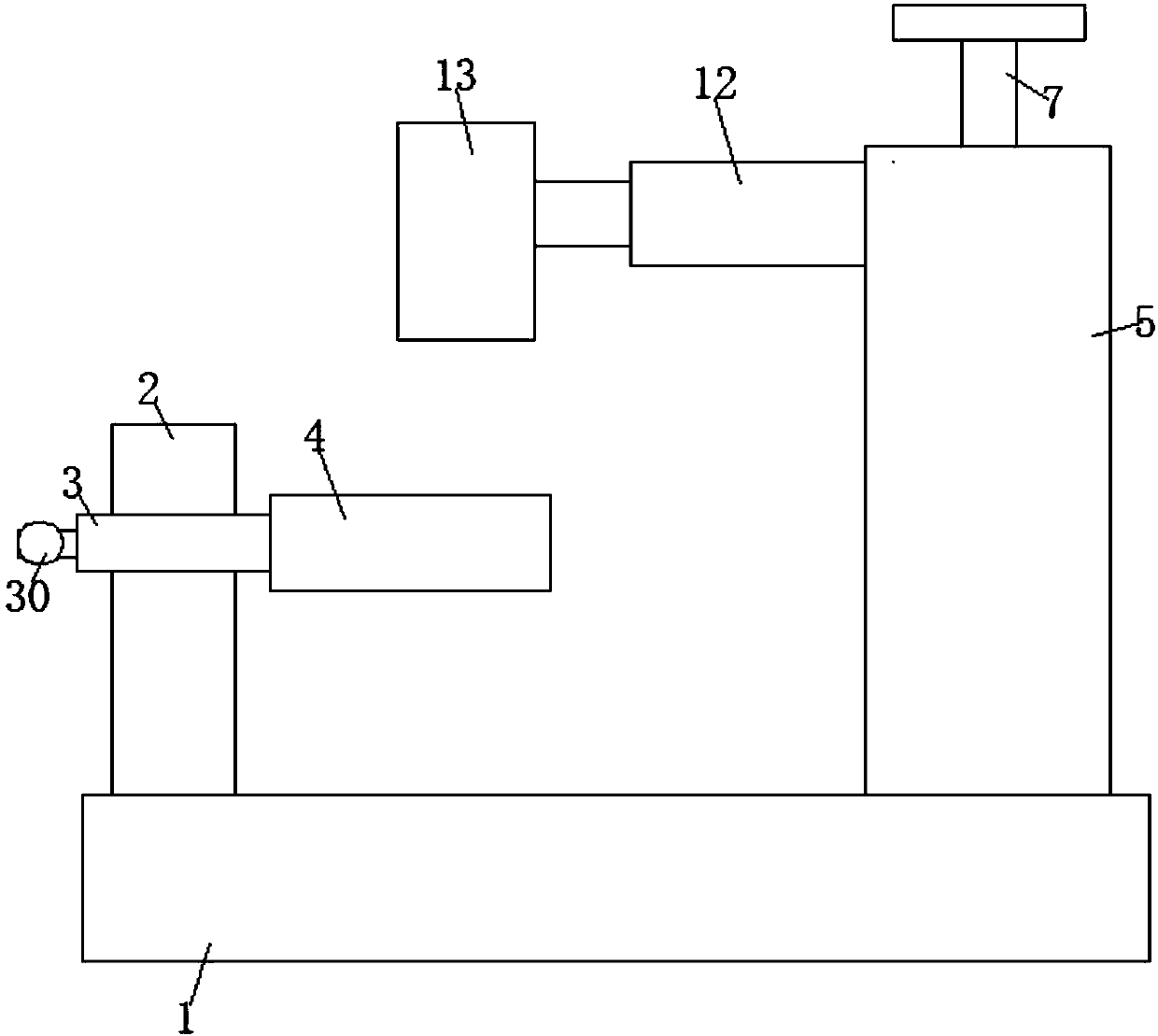

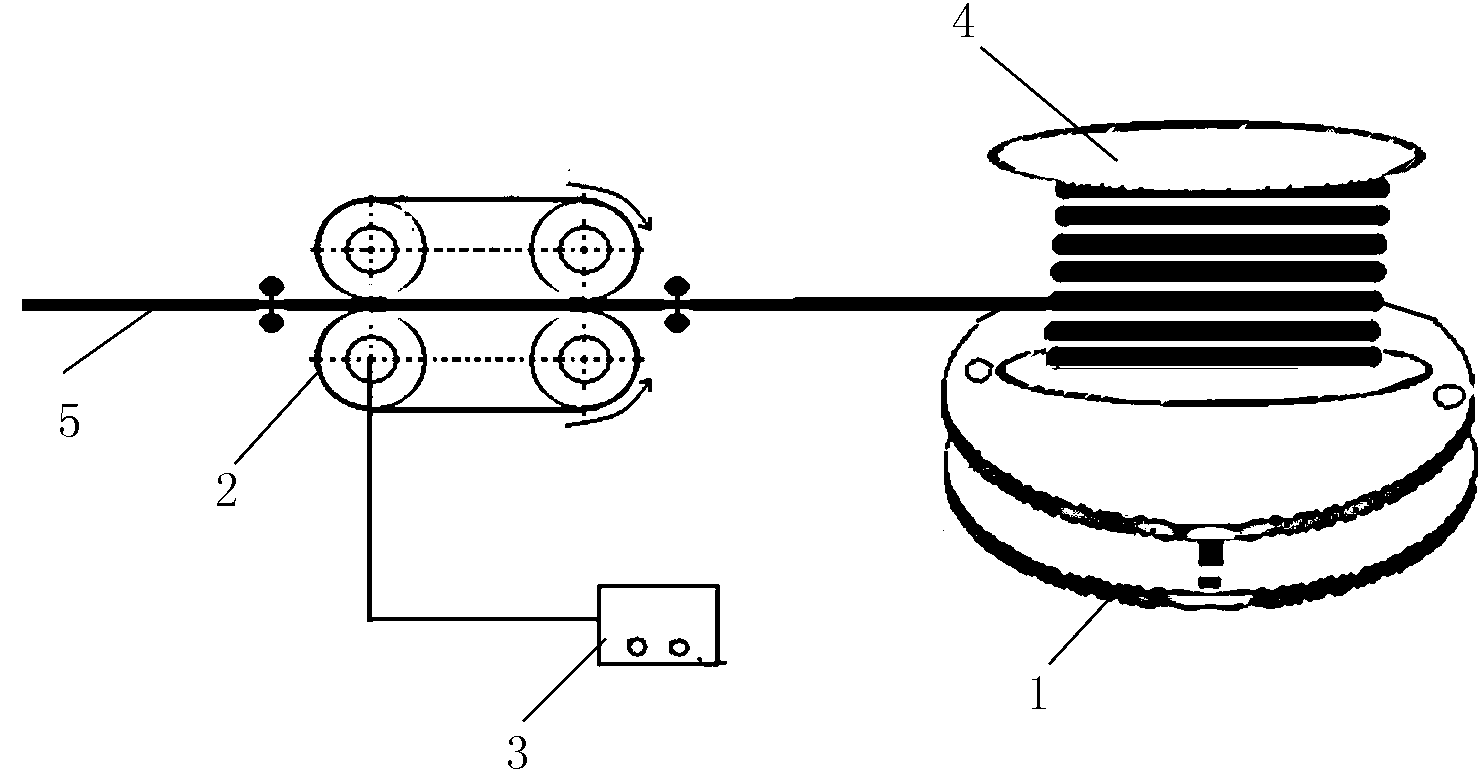

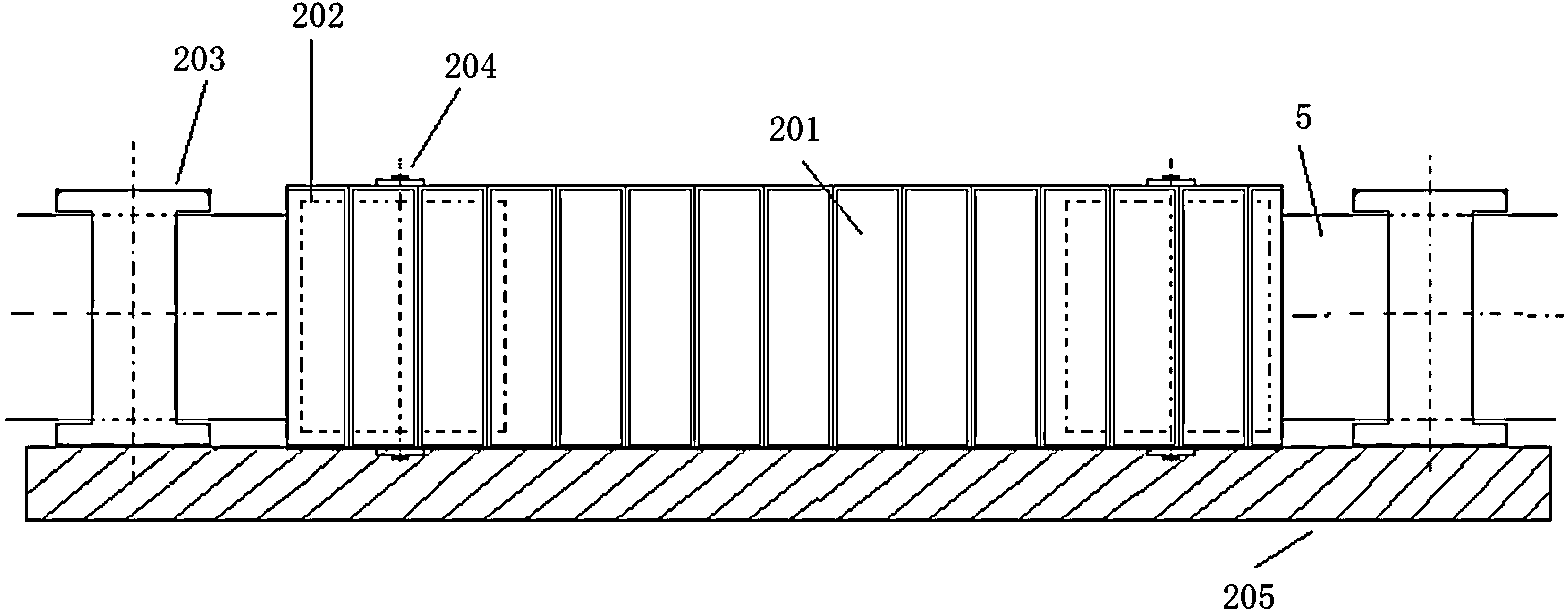

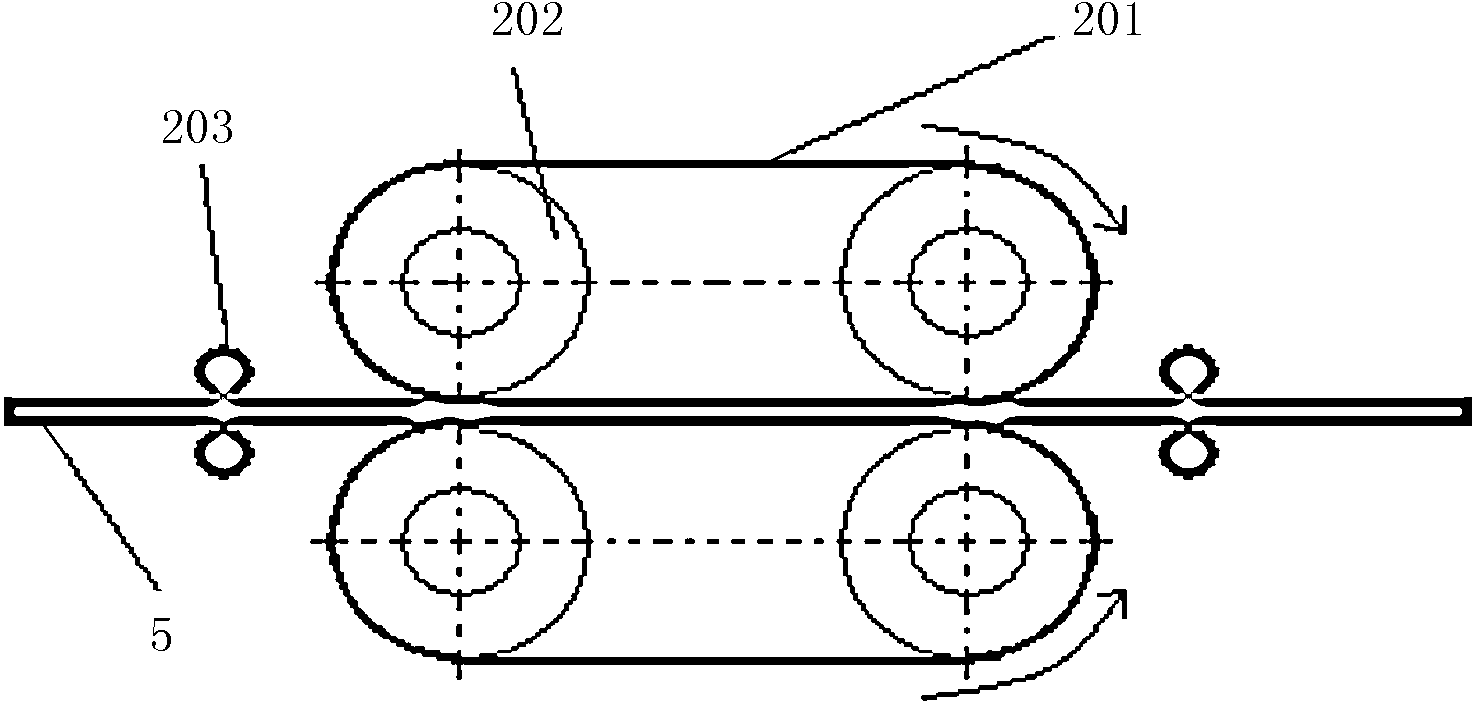

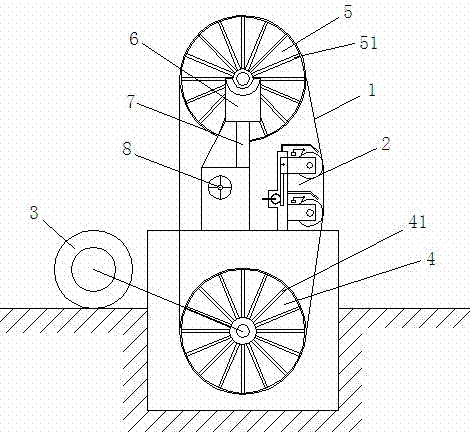

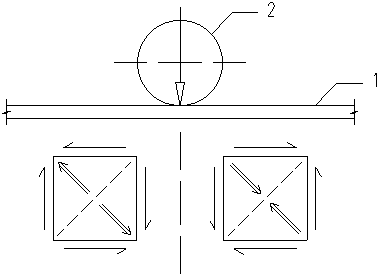

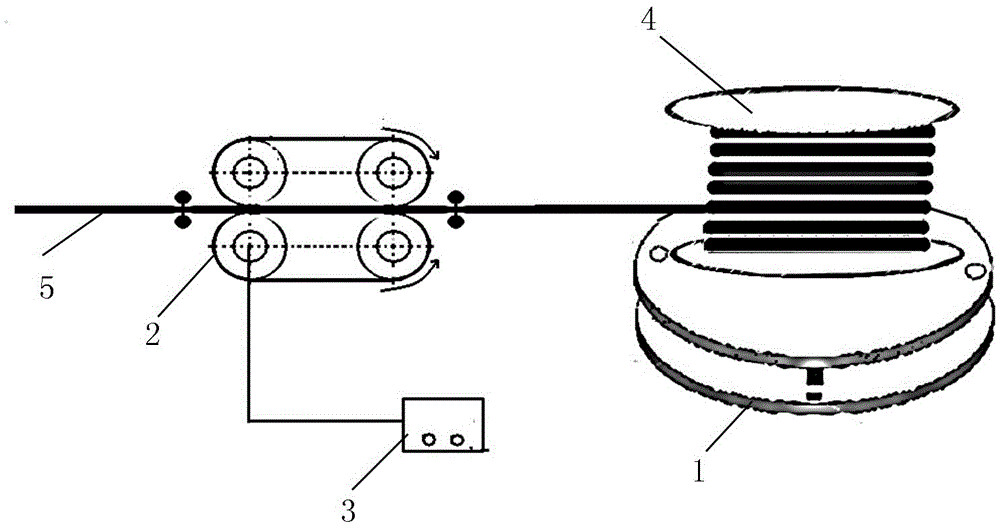

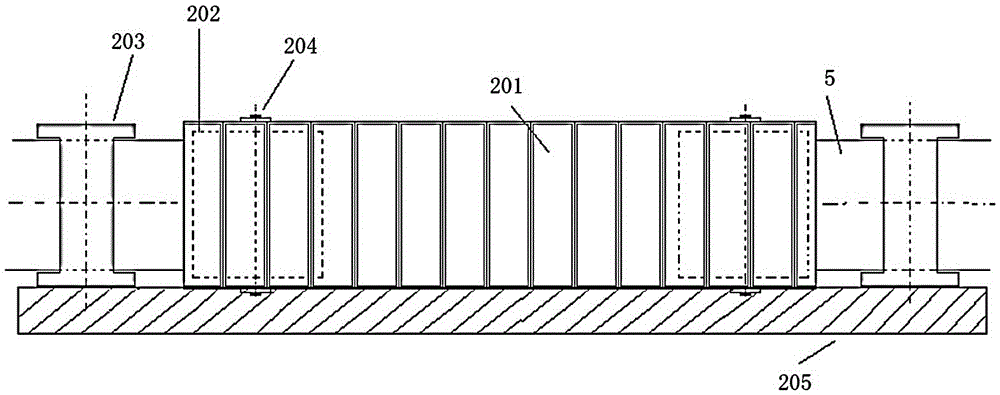

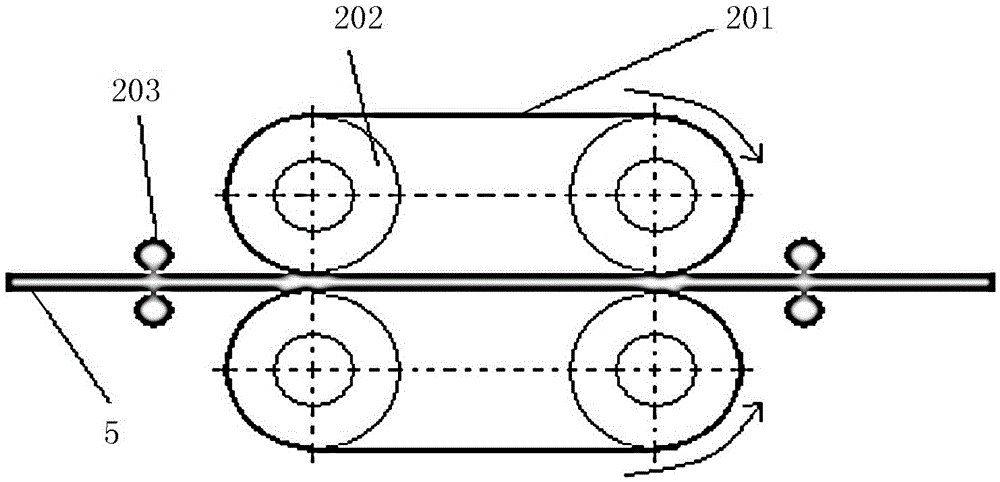

Abrasive disc type wire and cable assistance paying-off device

ActiveCN103199481AIncrease flexibilityEasy to control the direction of pay-offArrangements using take-up reel/drumFriction forceTime-Consuming

The invention relates to an abrasive disc type wire and cable assistance paying-off device for 1-10kV mesolow wires or cables. The abrasive disc type wire and cable assistance paying-off device structurally comprises an abrasive disc type paying off rack and an assistance device, wherein a rotary bearing shaft is arranged on the abrasive disc type paying off rack, and a cable drum is sleeved on the rotary bearing shaft; and a cable leading-out end on the cable drum is arranged between conveyer belts of the assistance device. By adopting the abrasive disc type wire and cable assistance paying-off device, the problems that a lot of manpower is required, the paying-off process is time-consuming and labor-consuming and the like when lines are constructed and cables are paved are solved, the influence of the ground to the paying off rack is eliminated, and the paying-off direction is convenient to control; and due to the assistance device and a control device, the friction force between the cables and the ground surface is reduced, so that the paying off process is time-saving and labor-saving and easy to control, can be finished by two persons, and a lot of manpower is saved.

Owner:STATE GRID CORP OF CHINA +1

Cable bridge with anti-wear function

Owner:成都协恒科技有限公司

Sawing machine provided with high-precision saw blade positioning device

The invention discloses a sawing machine provided with a high-precision saw blade positioning device. The sawing machine comprises a saw blade, a saw blade transmission device and the saw blade positioning device, the saw blade positioning device abuts on the saw blade to enable a saw blade cutting area to be vertical, and comprises an upper positioning wheel and a lower positioning wheel, and the upper positioning wheel and the lower positioning wheel with wheel faces abutting on the saw blade are arranged at the upper end and the lower end of a support frame respectively. The sawing machine is simple in structure, the positioning device is high in precision, rolling friction force of the saw blade and the upper and lower positioning wheels is small, the upper and lower positioning wheels are free of wear and shaking after long-time use, the saw blade in the cutting area is in an optimal vertical tensioning state constantly, left-right eccentricity can be avoided during operation of the saw blade, sawn wood lines hardly have any deviation, and the sawing machine is more obvious in advantages particularly when used for making veneers, and is cost-saving and high in production efficiency.

Owner:沭阳县贤官福星木业制品厂

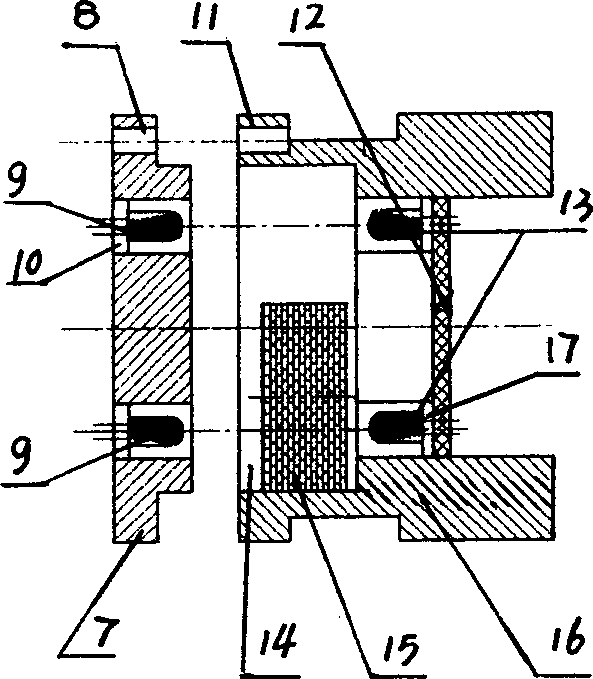

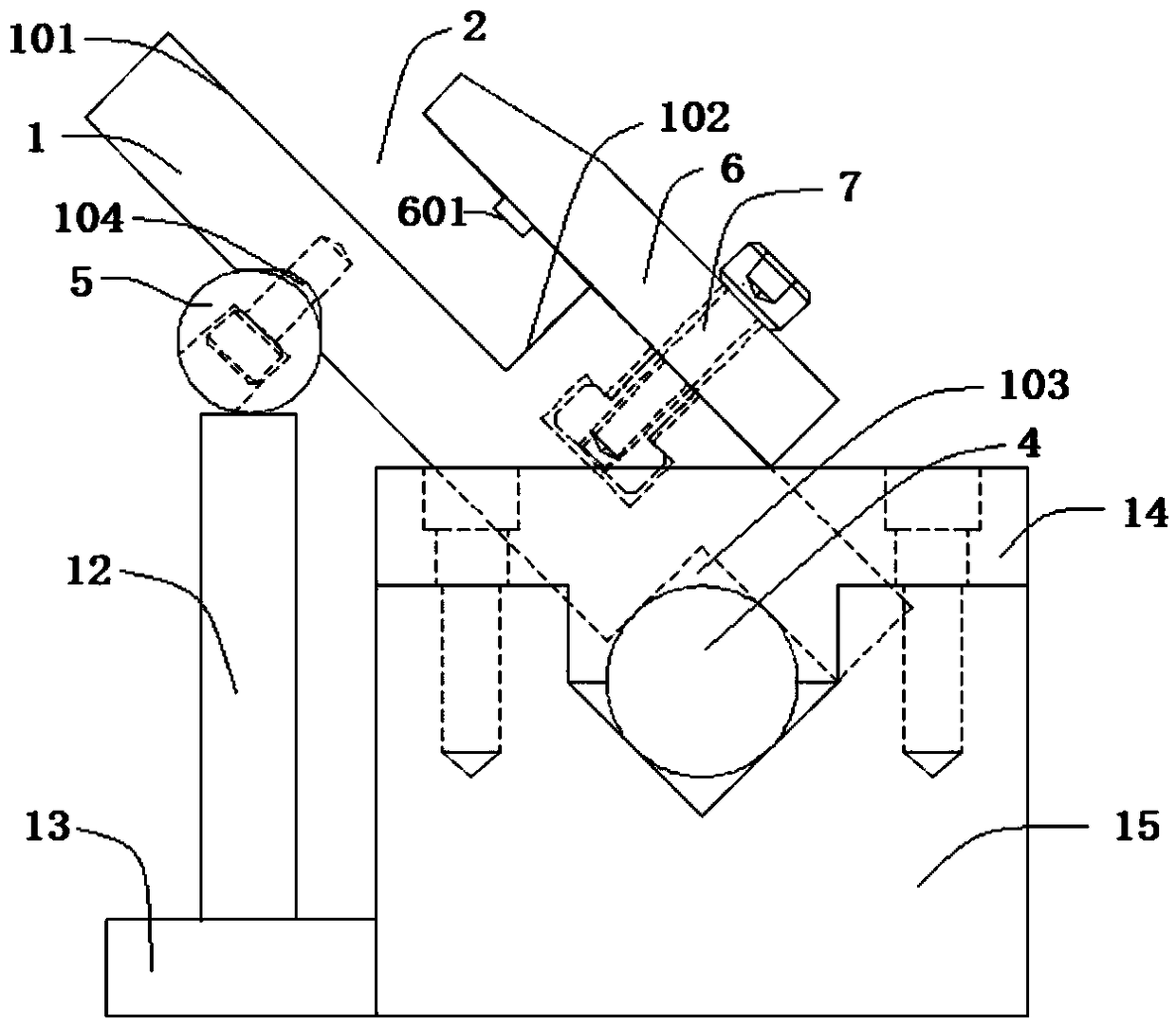

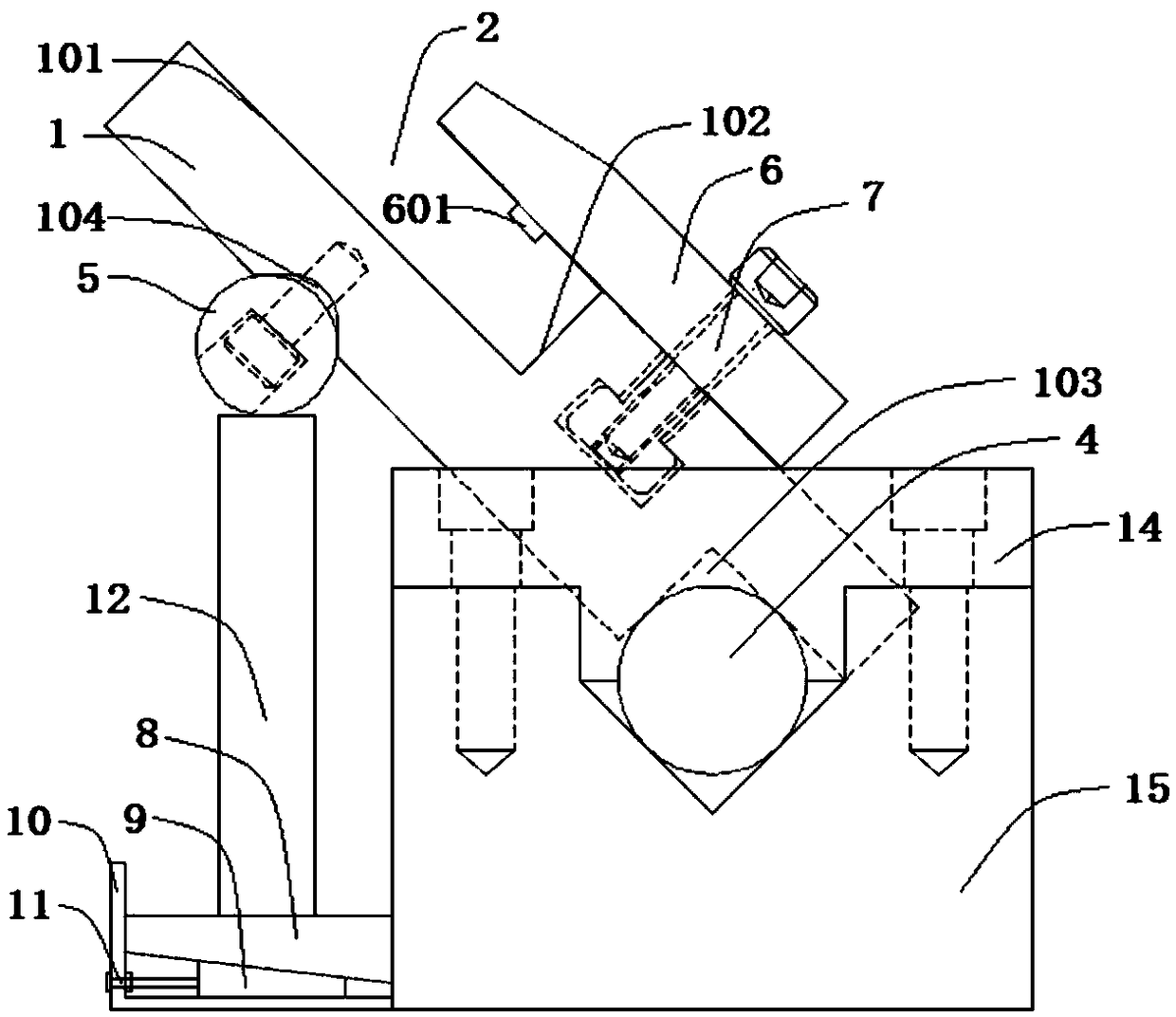

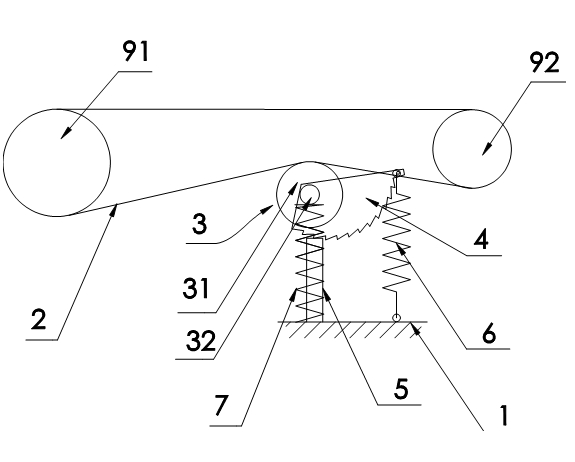

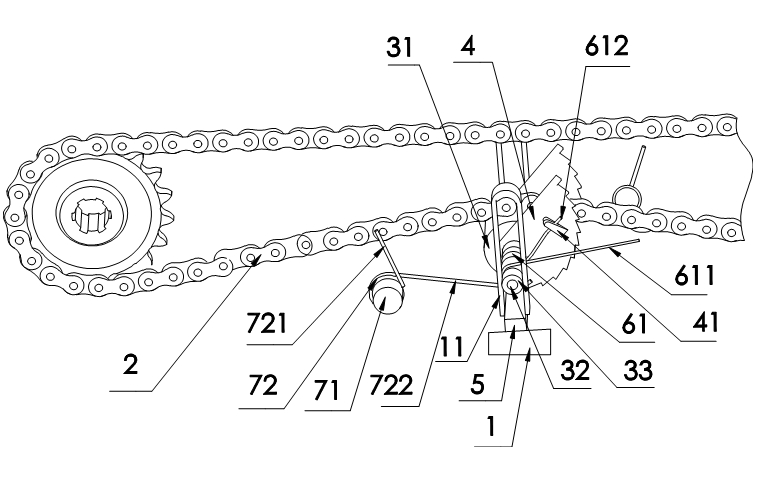

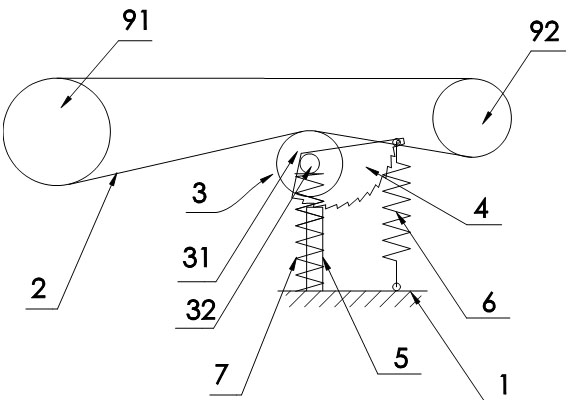

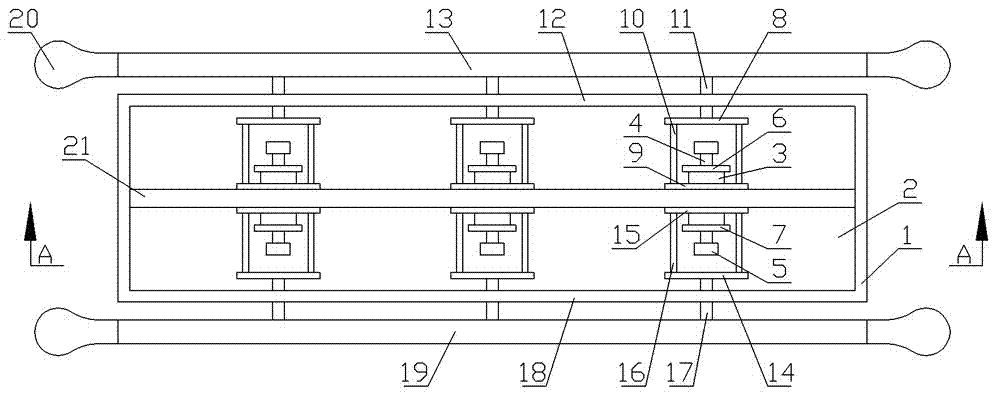

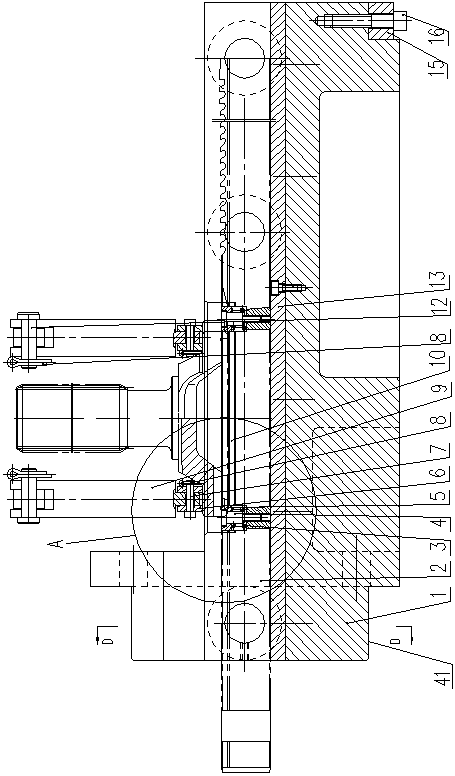

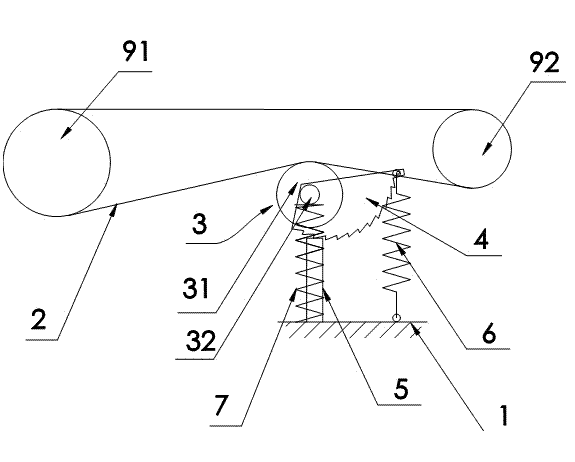

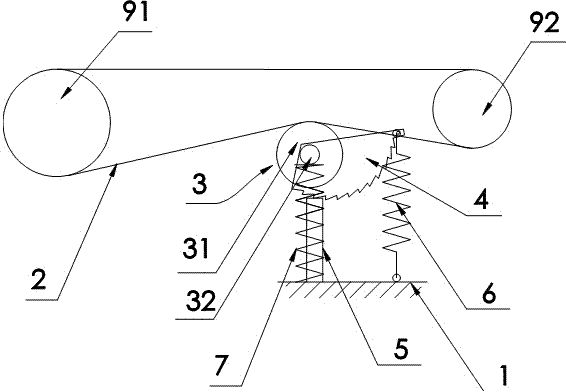

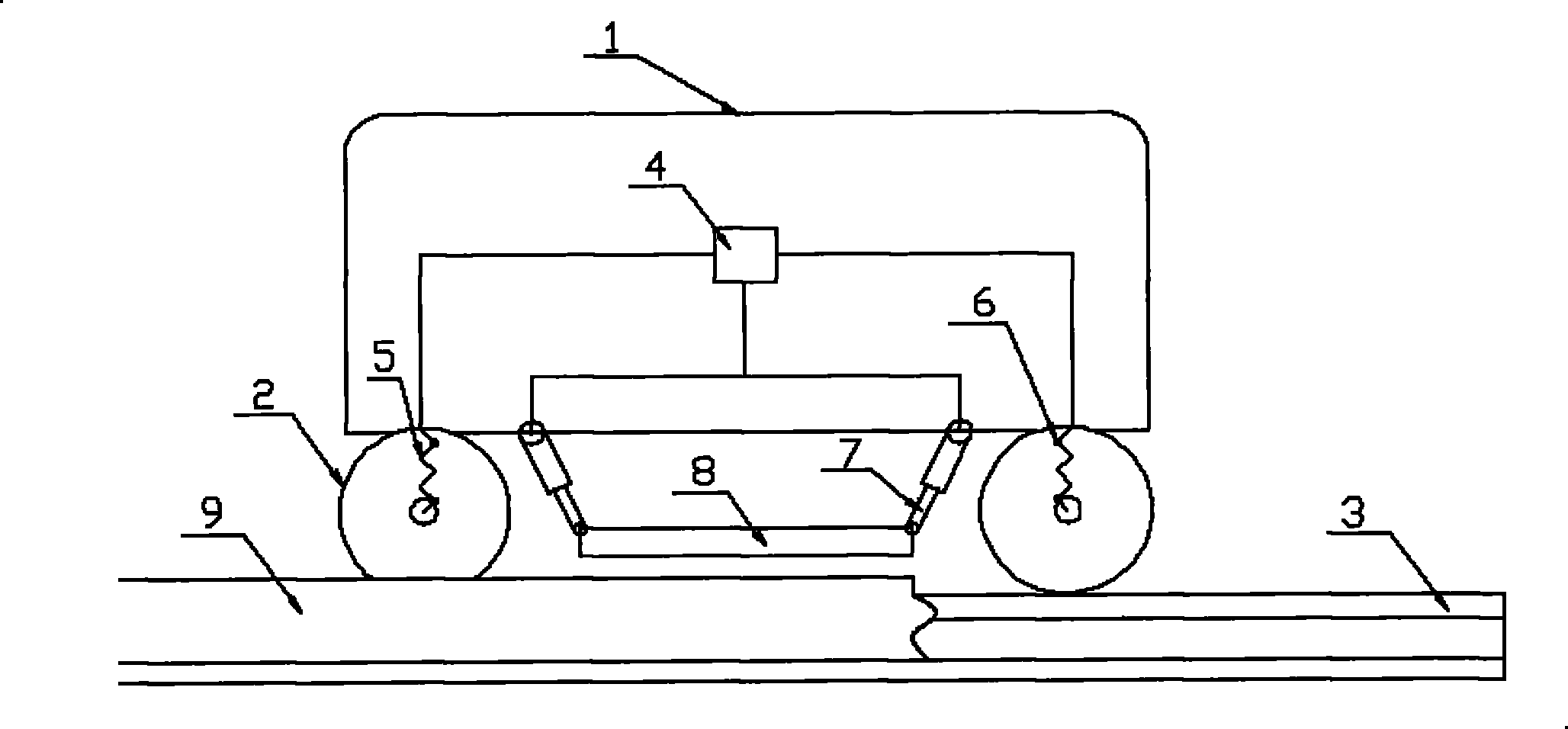

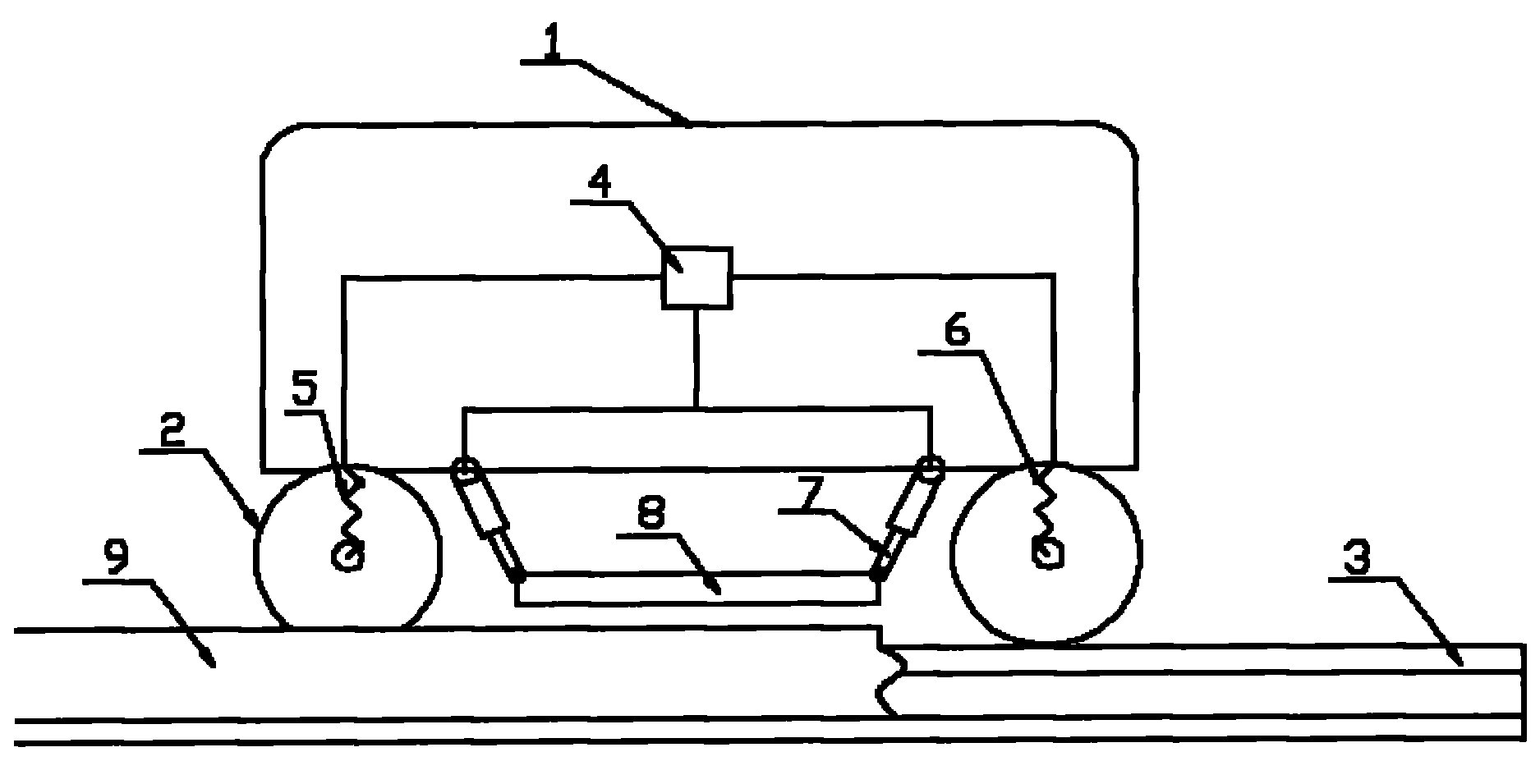

Reciprocating displacement type fatigue testing machine

ActiveCN102564872ALow rolling frictionReduce test energy consumptionMaterial strength using repeated/pulsating forcesFatigue testingEngineering

The invention relates to a reciprocating displacement type fatigue testing machine. The reciprocating displacement type fatigue testing machine comprises a tested steel beam, an acting wheel, a connecting bar, a double-acting oil cylinder, an oil cylinder support, a lifting rod, a load gravity block, a working platform and a hydraulic pump, wherein the acting wheel is connected with one side of the double-acting oil cylinder by the connecting bar; the double-acting oil cylinder is connected with the oil cylinder support and connected with the hydraulic pump; the hydraulic pump is connected with a control system; one end of the lifting rod is connected with a wheel axle of the acting wheel; the other end of the lifting rod is connected with the load gravity block; the acting wheel is positioned above the tested steel beam; and the load gravity block is inserted into a spatial position in the working platform. By using the reciprocating displacement type fatigue testing machine the restriction that the traditional fatigue testing machine only can test the positive stress variation induced fatigue is overcome and the bearing capability of the fatigue caused by bent member web shear stress inversion can be detected. The reciprocating displacement type fatigue testing machine provided by the invention has the following advantages that: the position of the acting force moves in a reciprocating way while the size and direction of the acting force is invariable; and the acting force is realized by a lifting rod pressurizing weight and small thrust and low testing energy consumption are required in the double-acting oil cylinder for driving the acting wheel.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

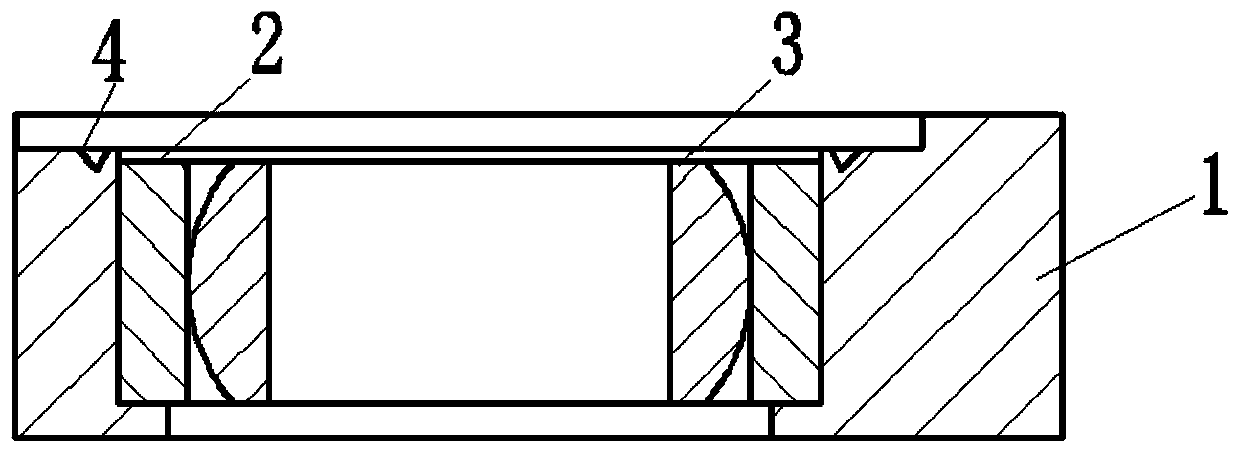

Magnetic suspension bearing

InactiveCN101761571ALow rolling frictionIncrease speedBearing componentsBearingsRolling resistanceMagnetic poles

The invention provides a magnetic suspension bearing comprising an inner ring, an outer ring and a retainer, wherein a annular closed magnet is made of neodymium iron boron to form the mutual repulsion between the inner ring and the outer ring, the contact faces of annular closed magnet and the inner ring and the outer ring are homopolar, a plurality of fixed bayonets are also arranged on both sides of the inner ring, are made of magnetic metal and have the same magnetic poles with the outer surface of the outer ring, and the outer edges of the bayonets are clamped on the outer surface of the outer ring and fix the outer ring. The magnetic suspension bearing has the advantages that by utilizing the principle of homopolar repulsion of a magnetic material, the magnetic material is applied to the bearing so that the inner ring and the outer ring of the bearing generate mutual repulsion to generate the function of suspension, and therefore, the magnetic suspension bearing greatly reduces the contact rolling friction force between members and enhances the rotating speed.

Owner:唐秀庚

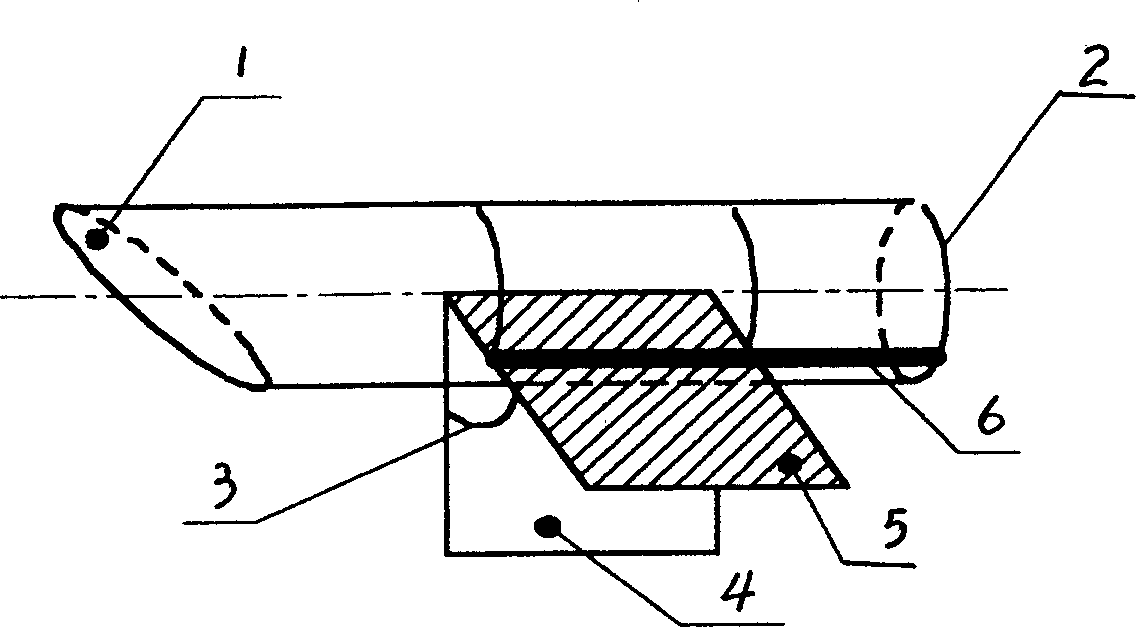

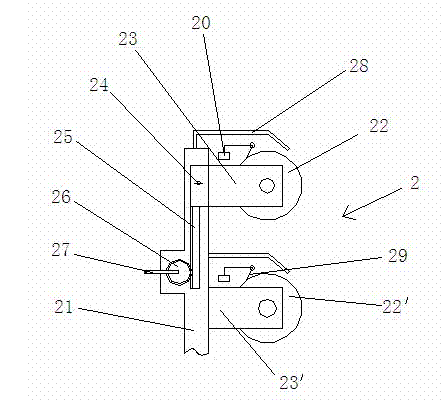

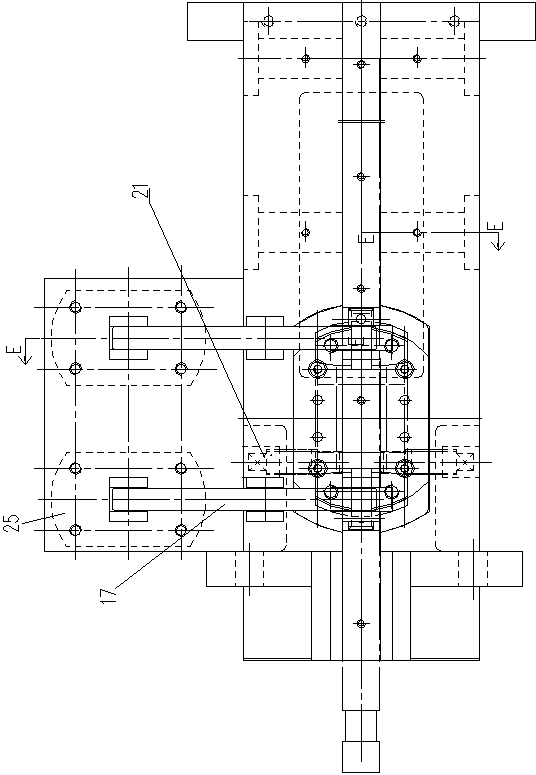

Broaching fixture for key groove of connection fork sleeve

ActiveCN102794655AGuaranteed machining accuracyReduce labor intensityPositioning apparatusBroaching machinesHead pressingEngineering

The invention discloses a broaching fixture for a key groove of a connection fork sleeve, which comprises a fixture body, wherein a rabbet adapted to a machine tool is formed in the left end of the fixture body; a broach backing plate is arranged on the fixture body; a broach is arranged on the broach backing plate; the fixture body is connected with a locating disc which is used for locating the excircle and the end face of a workpiece; the broach penetrates through the locating disc; and two workpiece pressing devices for pressing the workpiece is arranged on the fixture body. Each of the two workpiece pressing devices comprises an oil cylinder, wherein connection plates are articulated with the tops of oil cylinder connection rods; supports are articulated with the middle parts of the connection plates; a pressing rod is articulated with the other end of each connection plate; and pressing heads are connected with the bottom ends of the pressing rods. When the broaching fixture is in operation, the pressing heads press the workpiece downwards; and the two workpiece pressing devices are arranged on two sides of the locating disc and used for pressing two ends of the workpiece. According to the broaching fixture for the key groove of the connection fork sleeve, on the premise that the processing precision of the workpiece is ensured, the labor intensity of a worker is reduced, and the production efficiency is greatly improved; in addition, the replacing frequency of the broach is reduced, and the cost of production and manufacturing is lowered.

Owner:XUCHANG YUANDONG DRIVE SHAFT +1

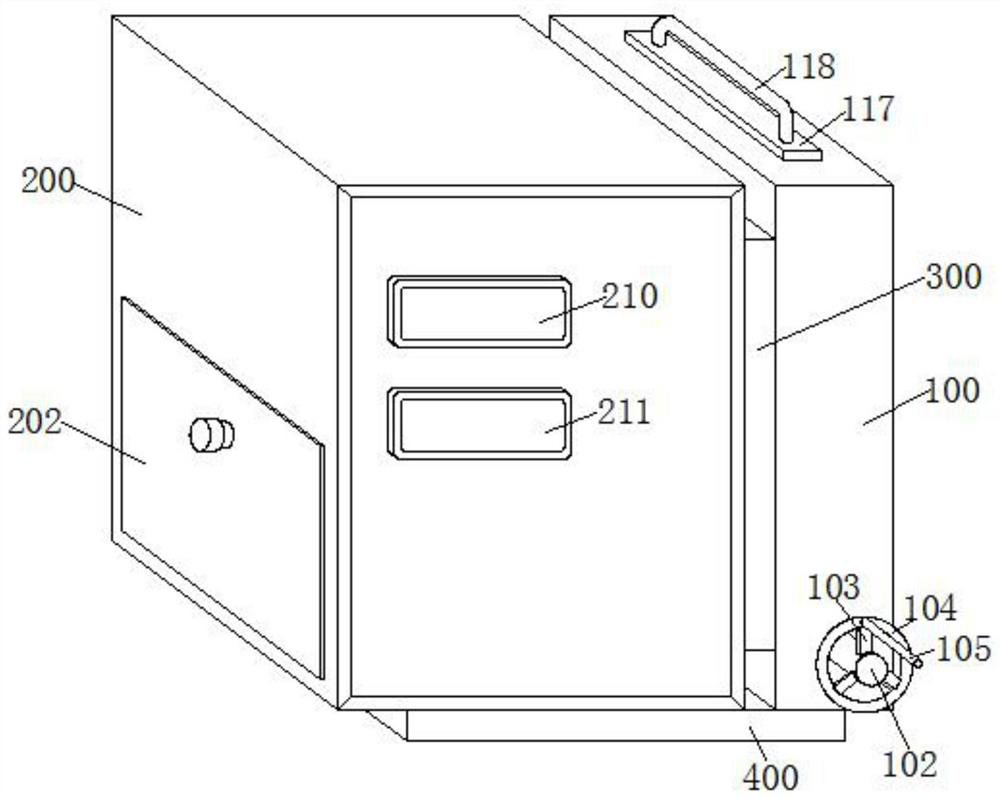

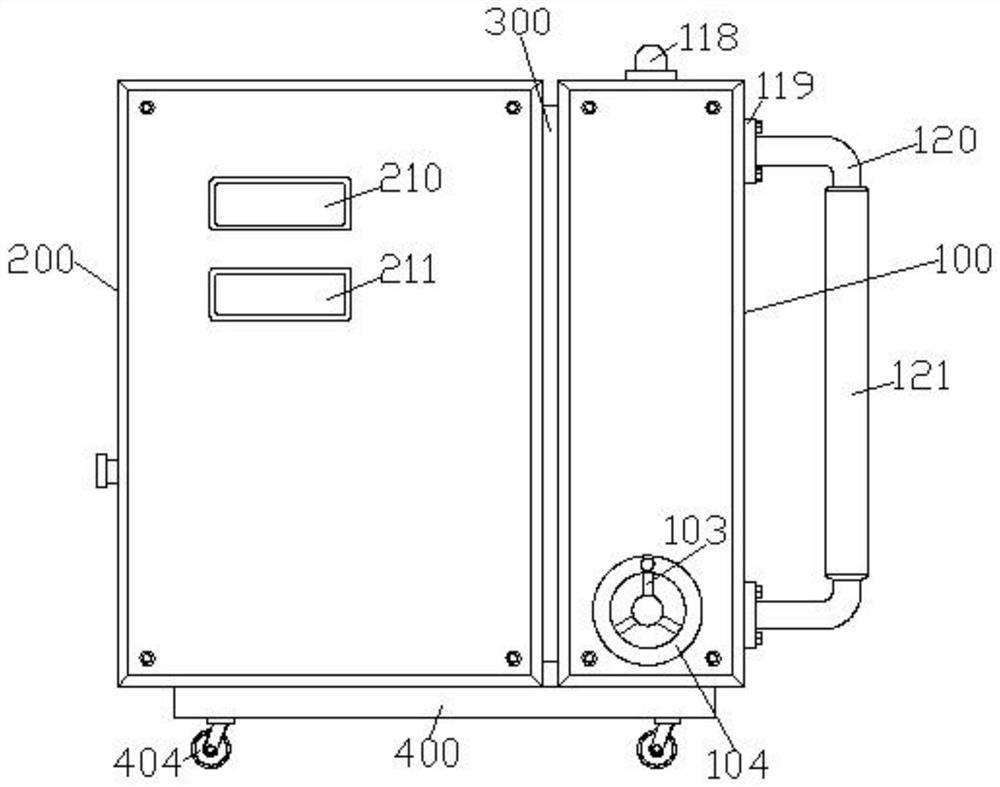

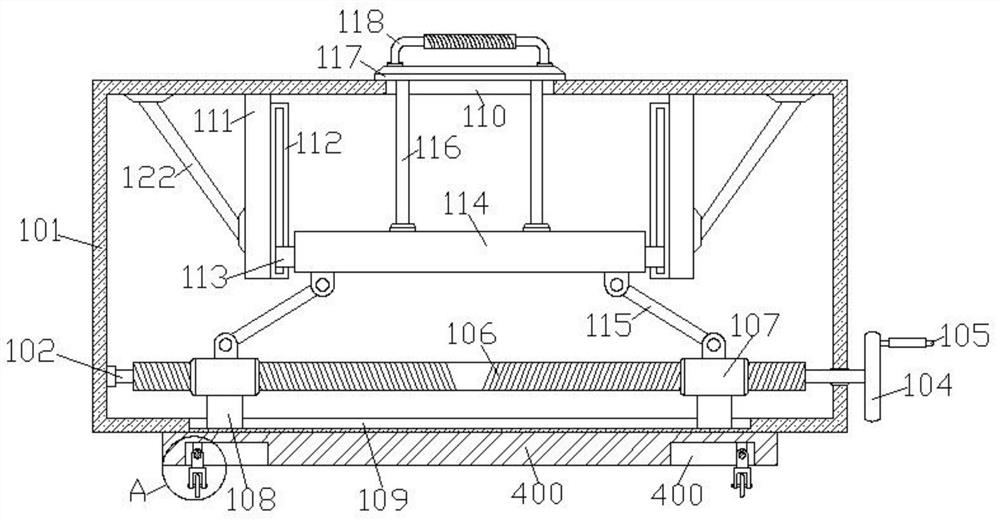

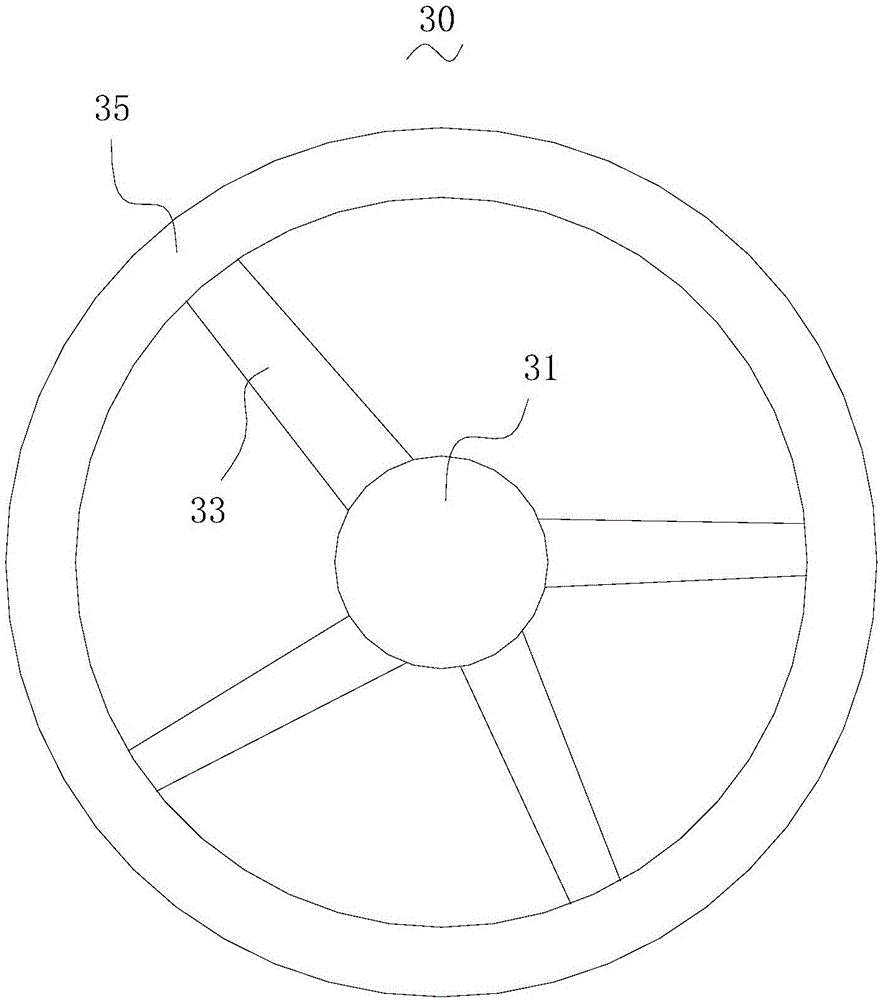

Portable nursery stock low-damage moisture rapid detection equipment and detection method

PendingCN111999207AImprove applicabilityLow rolling frictionWeighing by removing componentEngineeringRapid detection

The invention discloses portable nursery stock low-damage moisture rapid detection equipment and a detection method. The equipment comprises a pull rod telescoping mechanism and a detection mechanism,wherein a connecting plate is arranged between the pull rod telescoping mechanism and the detection mechanism; a mounting plate is arranged between the pull rod telescoping mechanism and the bottom of the detection mechanism; the pull rod telescoping mechanism comprises a main box body, a rotating shaft is arranged between the inner walls of the main box body, a two-way threaded rod is arranged on the outer surface of the rotating shaft, two symmetrical threaded sleeves are in threaded connection with the outer surface of the two-way threaded rod, connecting blocks are fixedly installed at the bottom of the threaded sleeves, and a sliding groove is formed in the inner bottom wall of the main box body. Moisture of a detection sample can be quickly dried and evaporated through an infrared baking lamp, and meanwhile, light rays can be focused on the top surface of the supporting plate through the plurality of reflectors, so that the moisture drying speed is increased.

Owner:HUAYI ECOLOGICAL LANDSCAPE ARCHITECTURE

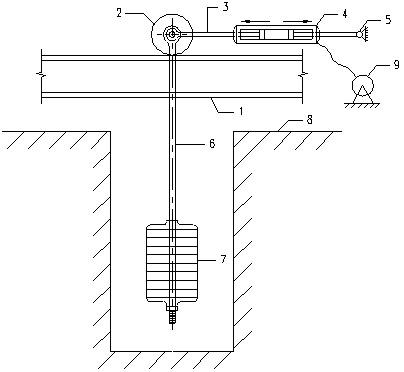

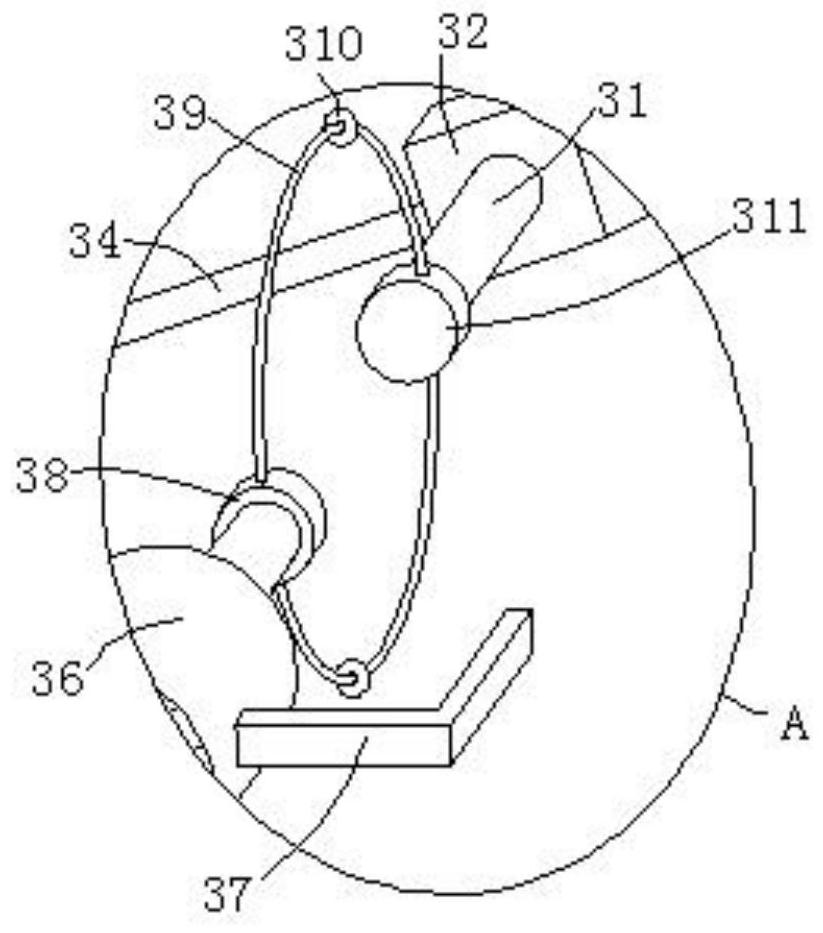

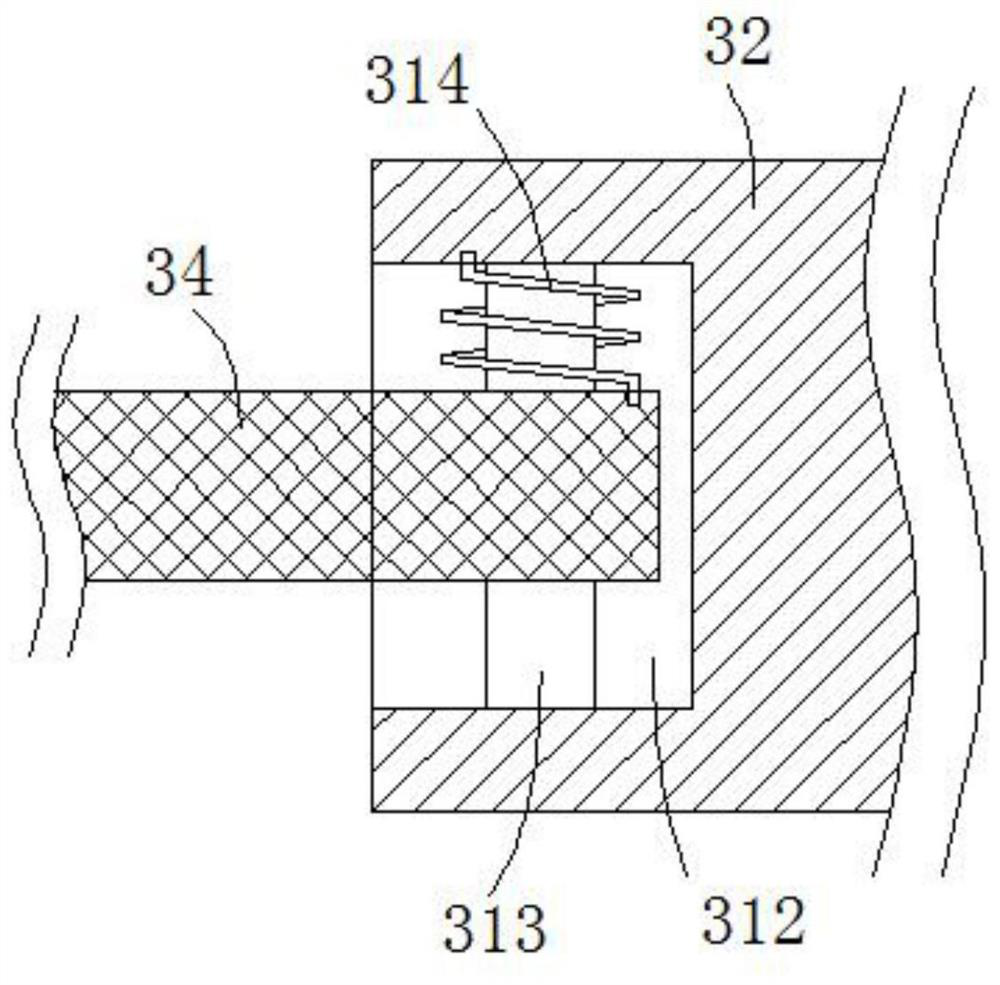

Lifting cable wire sliding device

InactiveCN108726374ALow rolling frictionEasy to drag the cableLoad-engaging elementsEngineeringPulley

The invention provides a lifting cable wire sliding device. The lifting cable wire sliding device comprises a coiling block with a motor, a guide rail and pulleys, wherein the coiling block is connected with a left pull steel cable and a right pull steel cable, the left pull steel cable is connected with one end of a track through a left pulley, the right pull steel cable is connected with the other end of the track through a right pulley, the guide rail is arranged on the V-shaped track, the pulleys are arranged on the guide rail and connected with connecting pieces through pulley shaft installing shafts, a cable is arranged at the bottoms of the connecting pieces, and the cable is connected to a drag cable. According to the lifting cable wire sliding device, the connecting pieces for installing the cable are arranged on the V-shaped track through the two pulleys, the rolling friction force is reduced, the cable is convenient to drag, on the track, the left pull steel cable and the right pull steel cable are connected to the track, the track can freely ascend and descend under driving of the motor, and different usage requirements are met.

Owner:YANGZHOU JUNRUI CHUANGZHI IND DESIGN

Reciprocating displacement type fatigue testing machine

ActiveCN102564872BLow rolling frictionReduce test energy consumptionMaterial strength using repeated/pulsating forcesControl systemHydraulic pump

The invention relates to a reciprocating displacement type fatigue testing machine. The reciprocating displacement type fatigue testing machine comprises a tested steel beam, an acting wheel, a connecting bar, a double-acting oil cylinder, an oil cylinder support, a lifting rod, a load gravity block, a working platform and a hydraulic pump, wherein the acting wheel is connected with one side of the double-acting oil cylinder by the connecting bar; the double-acting oil cylinder is connected with the oil cylinder support and connected with the hydraulic pump; the hydraulic pump is connected with a control system; one end of the lifting rod is connected with a wheel axle of the acting wheel; the other end of the lifting rod is connected with the load gravity block; the acting wheel is positioned above the tested steel beam; and the load gravity block is inserted into a spatial position in the working platform. By using the reciprocating displacement type fatigue testing machine the restriction that the traditional fatigue testing machine only can test the positive stress variation induced fatigue is overcome and the bearing capability of the fatigue caused by bent member web shear stress inversion can be detected. The reciprocating displacement type fatigue testing machine provided by the invention has the following advantages that: the position of the acting force moves in a reciprocating way while the size and direction of the acting force is invariable; and the acting force is realized by a lifting rod pressurizing weight and small thrust and low testing energy consumption are required in the double-acting oil cylinder for driving the acting wheel.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

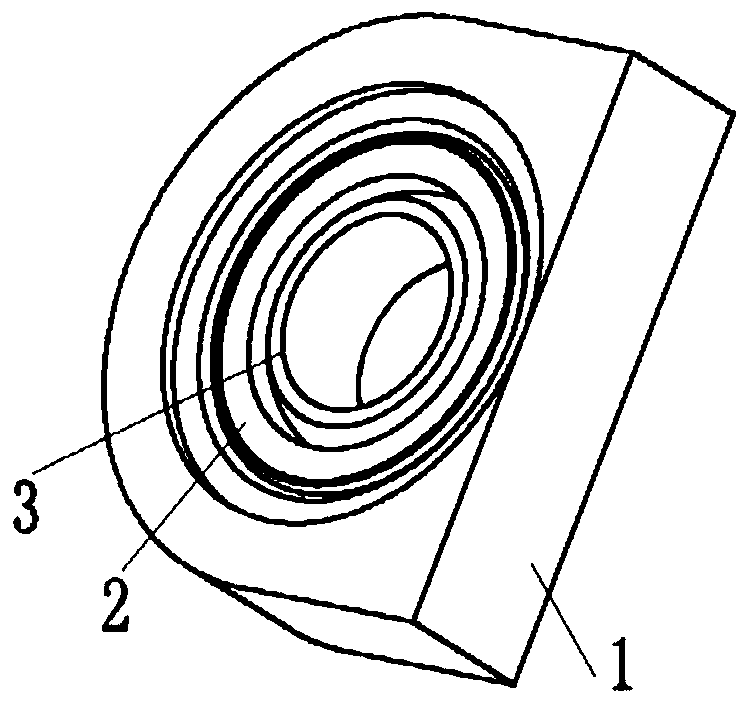

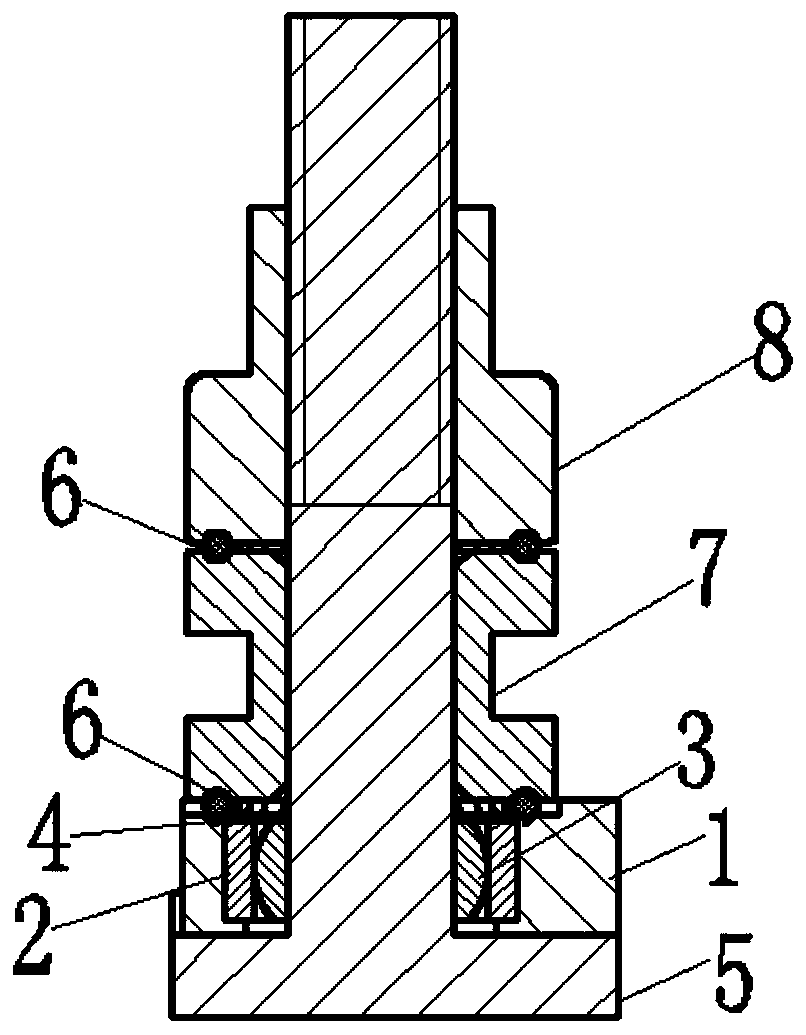

A portable joint bearing rolling closing device

Owner:NANJING CHENGUANG GRP

A permanent magnetic levitation auxiliary bearing

The invention relates to a permanent magnetic levitation auxiliary bearing which comprises two inner magnetic groups and two outer magnetic groups which are symmetrically and oppositely arranged on a shaft sleeve. Each inner magnetic group is composed of an annular inner magnetic solid boot, an inner magnetic ring, a wedge-shaped inner magnetic solid boot and a cylindrical roller which are sequentially arranged from inside to outside in the radial direction. The outer magnetic groups are fixed to the outer sides of the inner magnetic groups through special metal rings in the radial direction. Each outer magnetic group is composed of a wedge-shaped outer solid boot, an outer magnetic body and an annular outer magnetic solid boot which are sequentially arranged from inside to outside in the radial direction. An annular gap is reserved between each wedge-shaped outer magnetic solid boot and the corresponding cylindrical roller. The radial magnetization direction of the inner magnetic rings is opposite to that of the outer magnetic rings. The permanent magnetic levitation auxiliary bearing is in a magnetic levitation state when lightly loaded and has no mechanical friction. On the condition of heavy load, the outer magnetic groups and the inner magnetic groups are in rolling connection with the cylindrical rollers, and the bearing still has the high convolution precision and high bearing strength; in addition, due to the repelling force of the magnetic effect, the pressure of the cylindrical rollers on the wedge-shaped outer magnetic solid boots is greatly reduced, and rolling friction force between the cylindrical rollers and the wedge-shaped outer magnetic solid boots is greatly reduced.

Owner:ANSHAN GANGFENG FAN

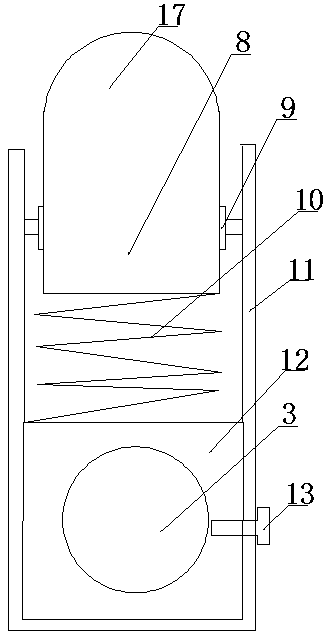

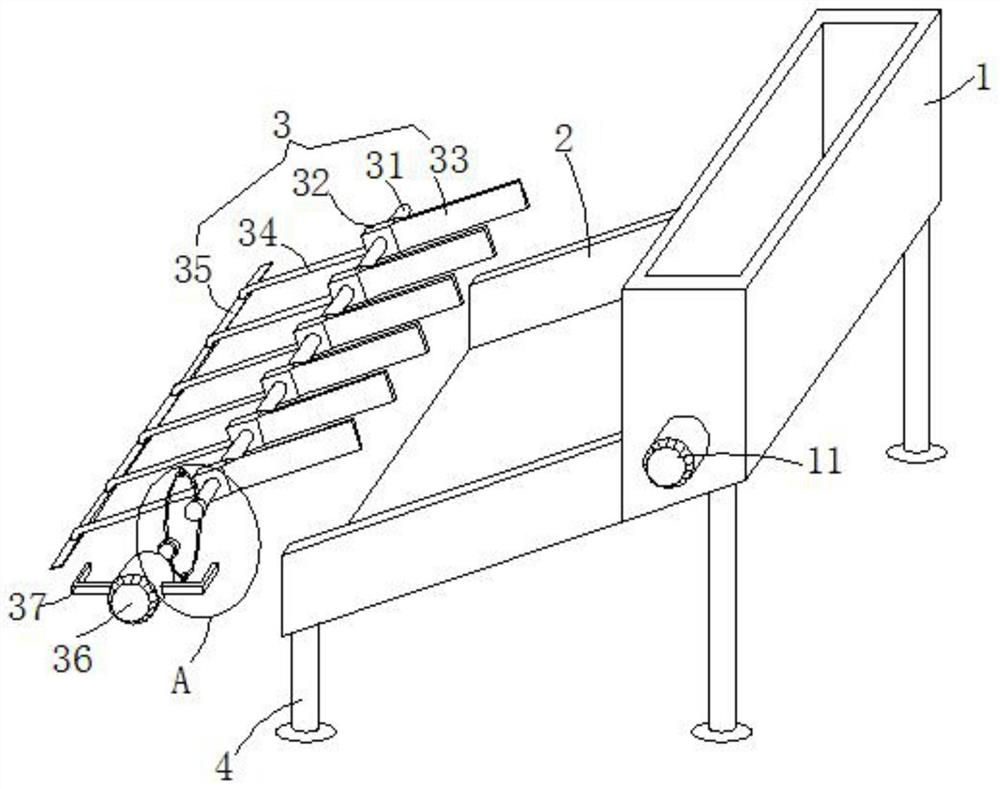

Rapid flattening device for feed production and screening and flattening method

InactiveCN112246623AIncrease productivityLow rolling frictionSievingScreeningProduction lineElectric machinery

The invention discloses a rapid flattening device for feed production and screening and a flattening method. The rapid flattening device comprises a material guiding plate, a feeding hopper and a flattening mechanism; the front end and the back end of the material guiding plate are integrally bent upwards by 90 degrees to form baffles; the material guiding plate on the bottom end surface of the feeding hopper is arranged in the mode of inclining leftwards and downwards by 45 degrees; the bottom end of the left end surface of the feeding hopper is fixedly welded to the right end surface of thematerial guiding plate; a discharging opening flush with the bottom end surface of an inner cavity of the feeding hopper is formed in the bottom end of the left end surface of the feeding hopper; andthe flattening mechanism comprises a driving motor, a connecting rod, a plurality of mounting bases and a plurality of pressing rods. According to the rapid flattening device, through front-back sliding of the connecting rod, the plurality of pressing rods and a plurality of push plates can be driven to be shifted forwards and backwards along the bottom end surface of the inner cavity of the material guiding plate, auxiliary flattening of feed raw materials with uneven thicknesses is achieved, and the production efficiency of the whole feed production line is improved.

Owner:安徽笑果农牧产业科技有限公司

Semi-magnetic suspension type vehicle

InactiveCN101508302BLow rolling frictionExtended service lifeSliding/levitation railway systemsRolling resistanceRepulsion force

The invention relates to a semi-magnetic suspension type engine. The body of the engine is connected with an industrial computer, wheels are connected with wheel springs, and each wheel spring is connected with a stress sensor, wherein the industrial computer is respectively connected with each stress sensor through four paths of sensor lines. A chassis of the engine body is provided with a lifting device, and the upper part of the lifting device is connected with the industrial computer through a lifting device line. The tail end of the lifting device is connected with a permanent magnet of the chassis of the engine body, and a track permanent magnet of which the width is equal to that of the permanent magnet of the chassis of the engine body is continuously distributed between two tracks, wherein the polarity of the permanent magnet of the chassis is opposite to that of the track permanent magnet which is continuously distributed between the two tracks. The permanent magnet of the chassis and the track permanent magnets are both made of strong permanent magnetic materials with high coercive force and high residual magnetism. The semi-magnetic suspension type engine has simple structure, and the load gravity of the engine body is counteracted by the repulsion force of two magnets so as to reduce the rolling friction of the wheels and steel rails. The state of a train is equivalent to that of empty running, thereby the semi the magnetic suspension type engine prolongs the service life of the steel rails, the wheels and the springs.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Vane assembly, compressor and air conditioner

ActiveCN110425139BReduce dragImprove scrolling efficiencyCompression machines with non-reversible cycleVacuum evaporation coatingFriction lossEngineering

The invention provides a sliding vane assembly, a compressor and an air conditioner. The sliding vane assembly includes: a sliding vane body; a needle roller groove is arranged on the sliding vane body, and needles are installed in the needle roller groove; At least one end of the groove wall is provided with a limit structure, the limit structure is used to limit the needle roller in the needle roller groove; the slide body is also provided with a cutout, and the cutout is used to remove the needle roller groove at the place where the limit structure is not set. The groove wall reduces the contact area between the needle roller groove and the needle roller. The slide assembly of the present invention reduces the resistance effect of the inner wall of the needle groove to the rolling of the needle, improves the rolling efficiency of the needle, reduces the rolling friction force between the slide and the roller, and reduces the friction loss of the needle. The new ceramic needle roller improves the wear resistance and self-lubricating performance, and avoids the occurrence of adhesive wear between the sliding plate, needle roller and roller. The diamond-like graphite-nitride composite coating in the needle groove has good self-lubrication and strong wear resistance, which improves the long-term operation reliability of the slide.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

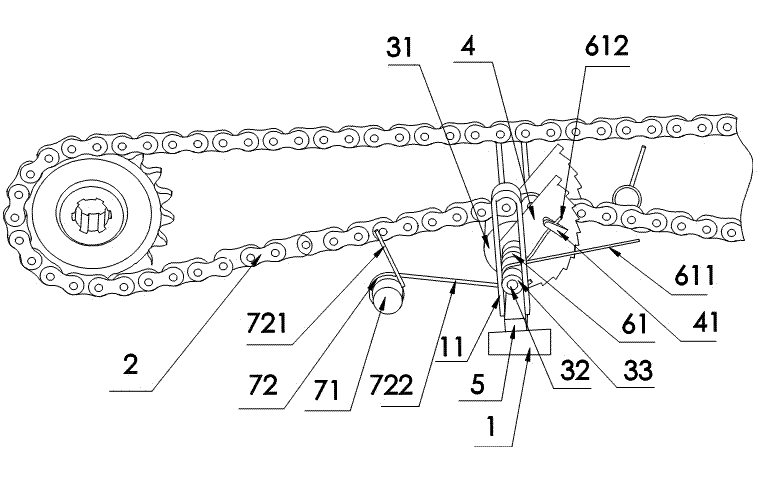

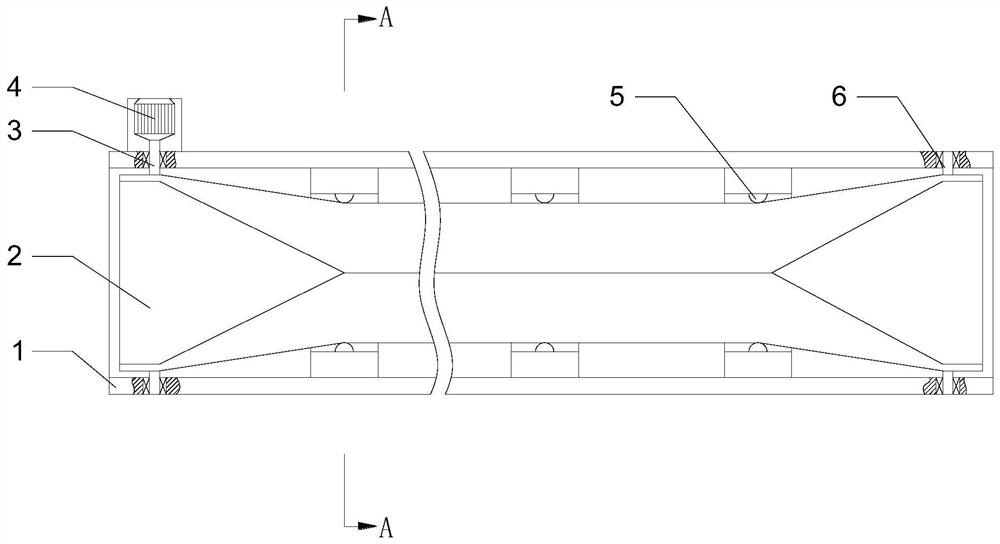

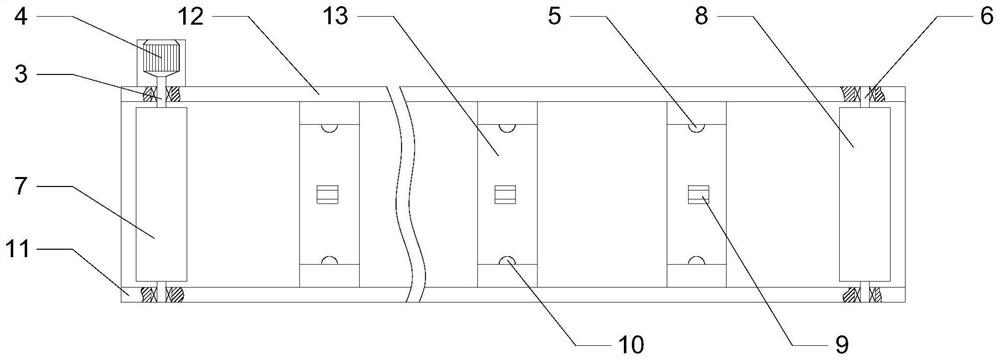

Portable ultra-long tubular belt conveyor

InactiveCN112278704ALow rolling frictionPlay a supporting roleConveyorsRollersAdhesive beltDrive shaft

The invention relates to the technical field of conveyors, in particular to a portable ultra-long tubular belt conveyor which is used for solving the problem that in the prior art, the material conveying distance of a conveyor is not long enough. The portable ultra-long tubular belt conveyor comprises a first vertical frame, a second vertical frame, a transverse frame, a driving shaft, a driven shaft, a driving roller, a driven roller and a conveying rubber belt; a left rolling mechanism is installed at the inner side of the first vertical frame, a right rolling mechanism is installed at the inner side of the second vertical frame, and a lower rolling mechanism is installed on the top face of the transverse frame; and a conveying cavity is reserved among the left rolling mechanism, the right rolling mechanism and the lower rolling mechanism, and the conveying rubber belt penetrates through the conveying cavity. According to the portable ultra-long tubular belt conveyor, the conveying rubber belt makes contact with the left rolling mechanism, the right rolling mechanism and the lower rolling mechanism in the material conveying process, in this way, small rolling friction force is mainly generated in the process that the conveying rubber belt operates on the transverse frame, and the smaller the friction force of the conveying rubber belt is, the longer the rubber belt can be conveyed, so that the conveyor can convey materials for a longer distance.

Owner:SICHUAN DONGLIN MINE TRANSPORT MACHINERY

Trolley

ActiveCN106428172AEasy rideImprove riding experienceCarriage/perambulator accessoriesCarriage/perambulator with multiple axesEngineeringMechanical engineering

Owner:JINHUA JINLONG TOOLS

Disc-type wire and cable power-assisted pay-off device

ActiveCN103199481BIncrease flexibilityEasy to control the direction of pay-offArrangements using take-up reel/drumEngineeringFriction force

The invention relates to an abrasive disc type wire and cable assistance paying-off device for 1-10kV mesolow wires or cables. The abrasive disc type wire and cable assistance paying-off device structurally comprises an abrasive disc type paying off rack and an assistance device, wherein a rotary bearing shaft is arranged on the abrasive disc type paying off rack, and a cable drum is sleeved on the rotary bearing shaft; and a cable leading-out end on the cable drum is arranged between conveyer belts of the assistance device. By adopting the abrasive disc type wire and cable assistance paying-off device, the problems that a lot of manpower is required, the paying-off process is time-consuming and labor-consuming and the like when lines are constructed and cables are paved are solved, the influence of the ground to the paying off rack is eliminated, and the paying-off direction is convenient to control; and due to the assistance device and a control device, the friction force between the cables and the ground surface is reduced, so that the paying off process is time-saving and labor-saving and easy to control, can be finished by two persons, and a lot of manpower is saved.

Owner:STATE GRID CORP OF CHINA +1

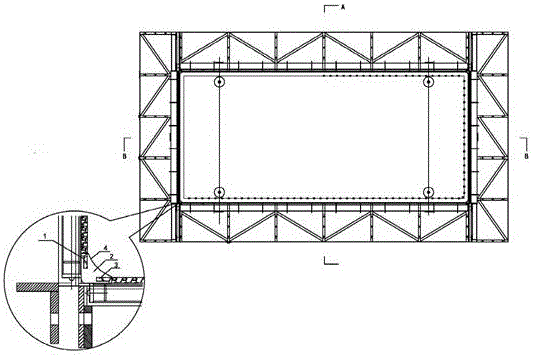

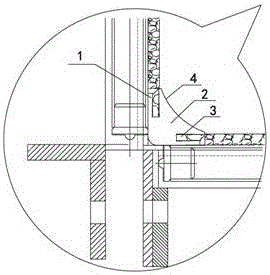

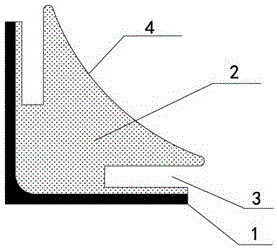

Connecting and fixing method for lining die of high bridge pier roller die

InactiveCN106835987ALow rolling frictionMobile and flexibleBridge erection/assemblyStructural engineeringWheel and axle

The invention discloses a connecting and fixing method for a lining die of a high bridge pier roller die. The technical scheme includes that a connecting and fixing device comprises equilateral angle steel, mounting notches and a rubber lining, wherein the equilateral angle steel wraps the high-density rubber lining, and the high-density rubber lining comprises the rubber mounting notches and an inner curved surface. During template splicing, a lining template is mounted in the rubber mounting notches of the device, the equilateral angle steel is positioned on the outer side to contact with a wheel axle directly, and the inner curved surface is positioned on the innermost side and contacts with concrete directly. The chamfer connecting and fixing device for the lining die of the high bridge pier roller die has the advantages that the device is portable, flexible to move, convenient to mount and excellent in connecting and fixing effects, mounting of the lining template is accelerated, the lining die at a chamfer position of a pier is convenient and compact to connect during roller die construction, the problem that the macromolecular resin lining die at the arc-shaped chamfer position of the pier is difficult to fix and connect is solved, construction progress can speed up, pier concrete appearance quality is guaranteed and economic benefit created by roller die construction is improved.

Owner:THE FOURTH ENG CO LTD OF CCCC FIRST HIGHWAY ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com