Abrasive disc type wire and cable assistance paying-off device

A technology of wire and cable and pay-off device, which is applied in the direction of using the reel take-up reel/photosensitive drum layout, etc., can solve the problems of high ground flatness requirements, time-consuming and laborious pay-off process, single pay-off direction, etc. Low rolling friction, easy control, flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] Such as Figure 3a-Figure 3b As shown, the structure of the disc-type pay-off frame 1 is that the chassis 101 is provided with a brake device 107, the center of the chassis 101 is provided with a rotating bearing shaft 102, and the wire supporting disc 103 is sleeved on the rotating bearing shaft 102. One end of the shaft 102 stretching out from the thread support tray 103 is provided with a suspension ring 105 , the thread support tray 103 is provided with a lifting hole 106 , and a universal wheel 104 is provided between the chassis 101 and the thread support tray 103 .

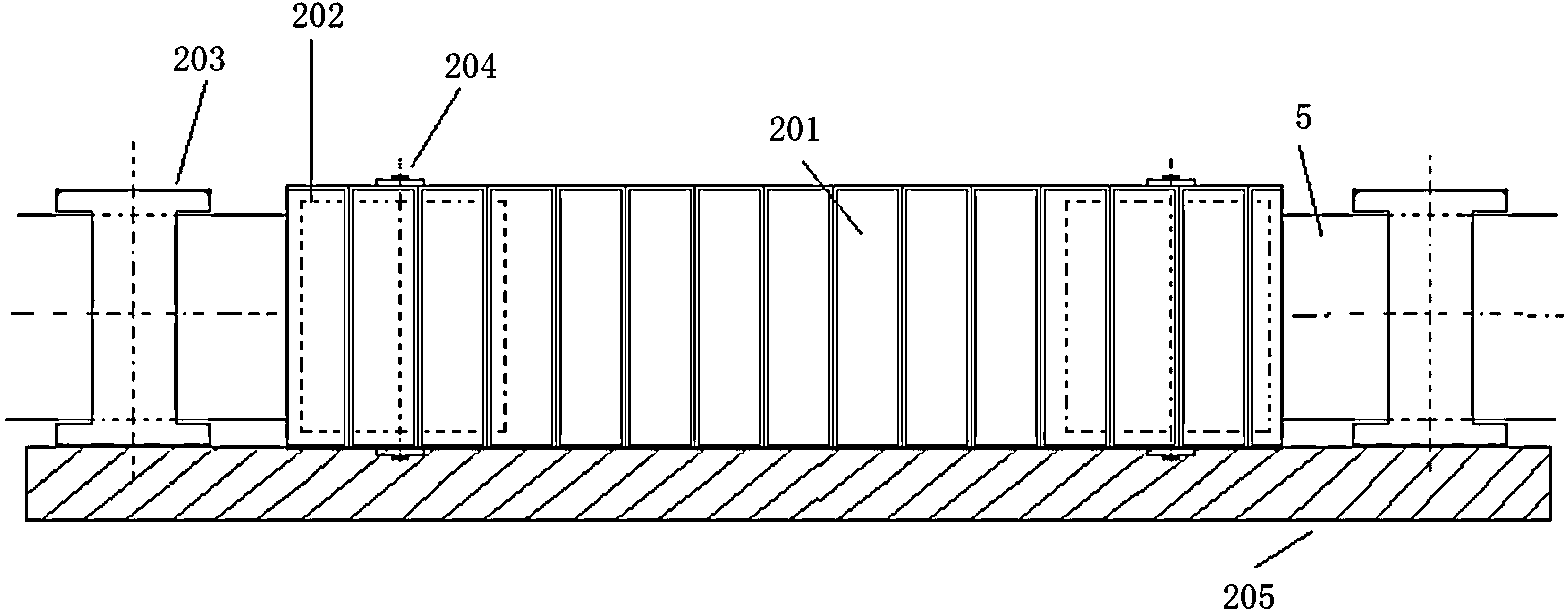

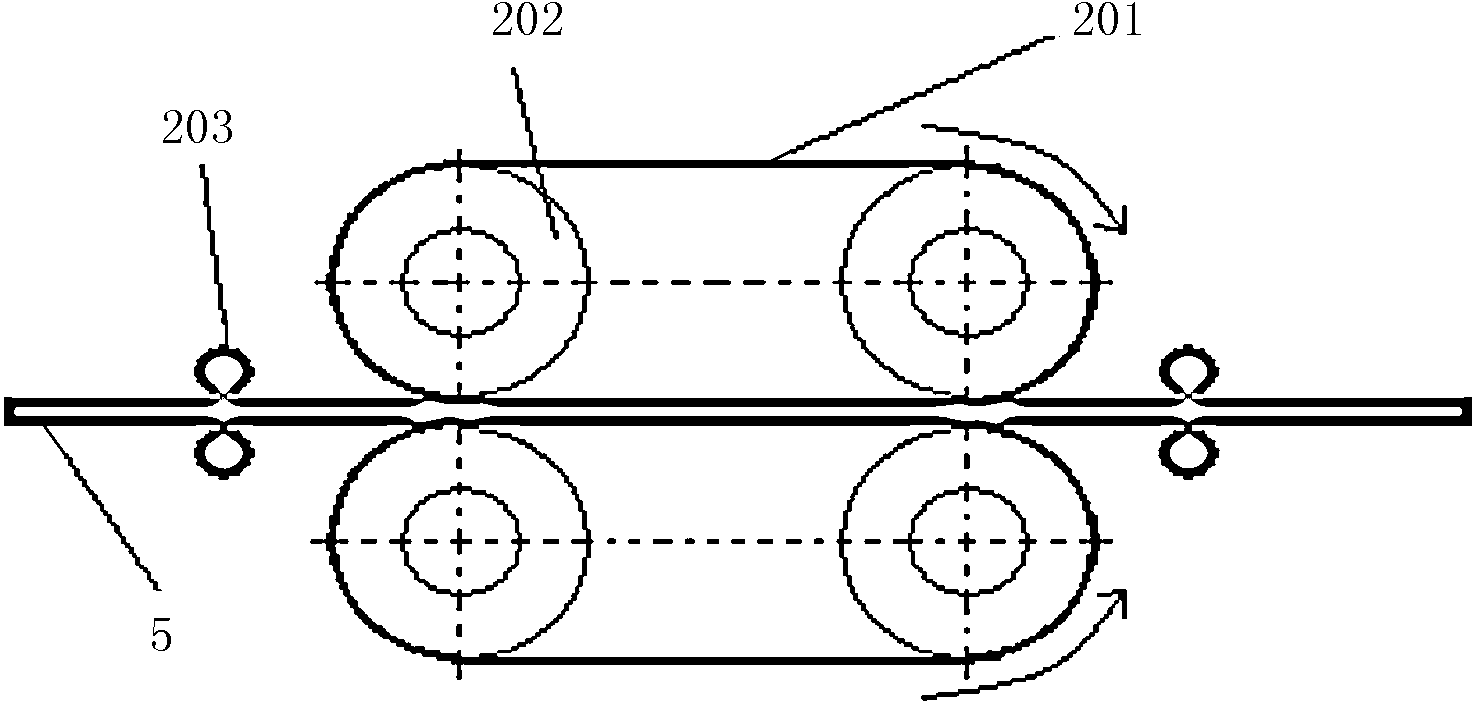

[0033] Such as Figure 2a-Figure 2c As shown, the structure of the booster device is that two groups of conveyor belts 201 are symmetrically arranged on the base 205, the conveyor belts 201 are set on the outer surface of the conveyor wheel 202, and the two ends of the conveyor belt 201 are provided with clamping devices 203 respectively.

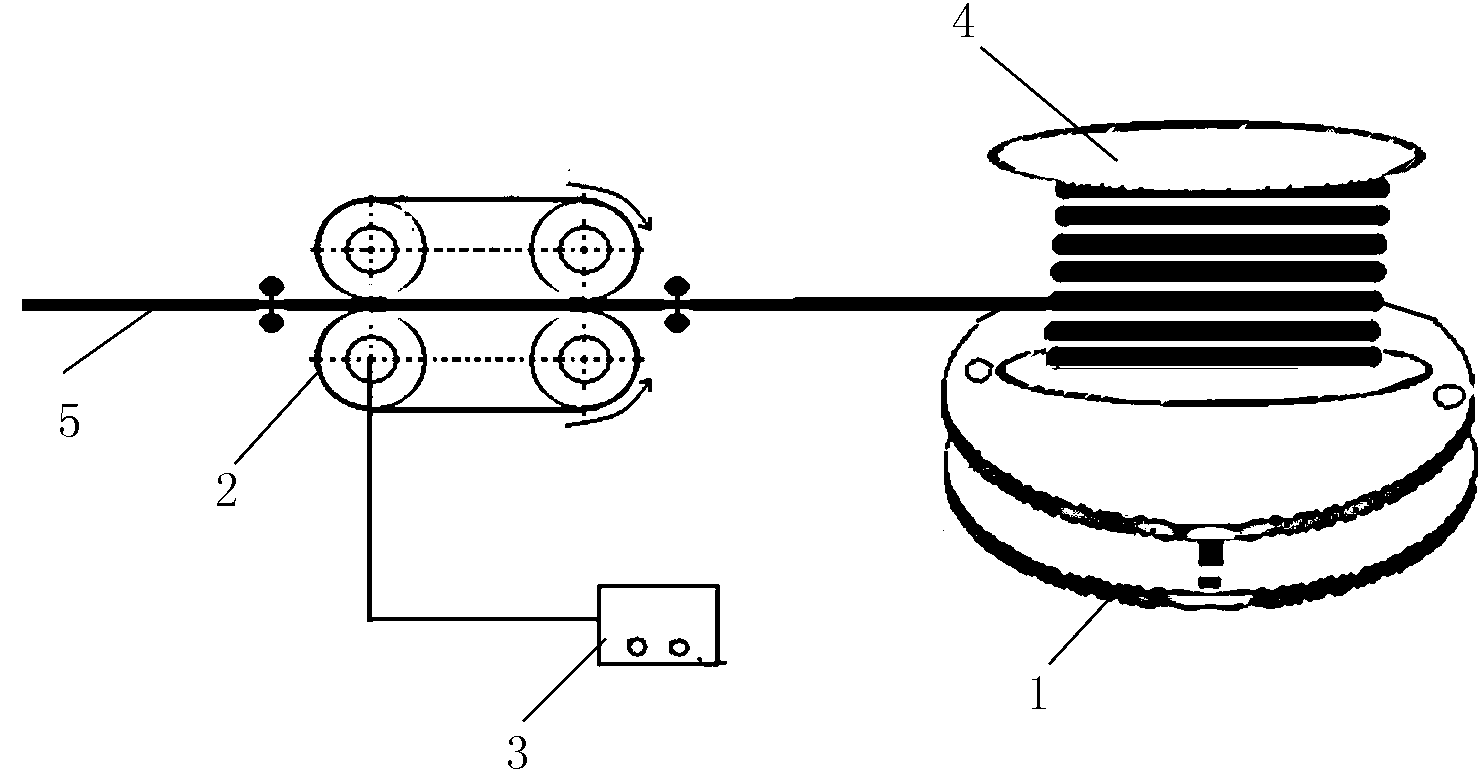

[0034] Such as figure 1 As shown, the cable reel 4 is set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com