Reciprocating displacement type fatigue testing machine

A fatigue testing machine, displacement technology, applied in the direction of applying repeated force/pulsation force to test the strength of materials, etc., can solve the problem of unable to test fatigue and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

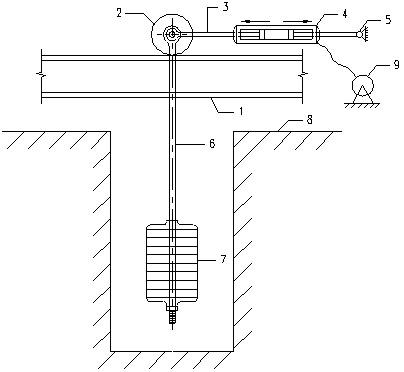

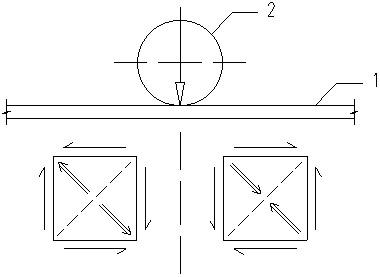

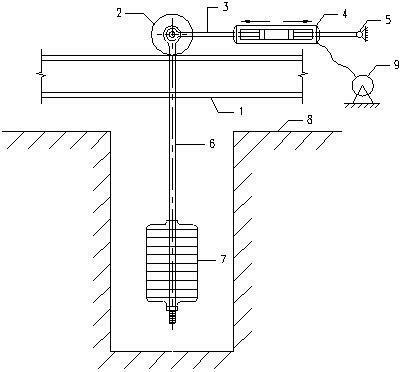

[0016] Embodiment 1: as figure 1 , consists of tested steel beam 1, action wheel 2, connecting rod 3, double-acting oil cylinder 4, oil cylinder support 5, boom 6, load gravity block 7, working platform 8 and hydraulic pump 9, and action wheel 2 passes through the connecting rod 3 is connected to the double-acting cylinder 4, the double-acting cylinder 4 is connected to the cylinder support 5, the double-acting cylinder is connected to the hydraulic pump 9, and the hydraulic pump 9 is connected to the control system; one end of the boom 6 is connected to the axle of the action wheel 2, and the other end of the boom 6 is connected to The load gravity block 7; the action wheel 2 is located above the steel beam 1 to be tested, and can move back and forth on the steel beam 1 to be tested; the load gravity block 7 is inserted into the space position in the working platform 8. Design the steel beam 1 to be tested according to the steel beam to be tested, and arrange the support pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com