Sawing machine provided with high-precision saw blade positioning device

A technology of positioning device and sawing machine, which is applied to sawing equipment, band saws, wood processing appliances, etc., can solve the problems of wood line deviation, waste, left and right eccentricity of saw blades, etc., and achieves the effect of enhancing stability and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

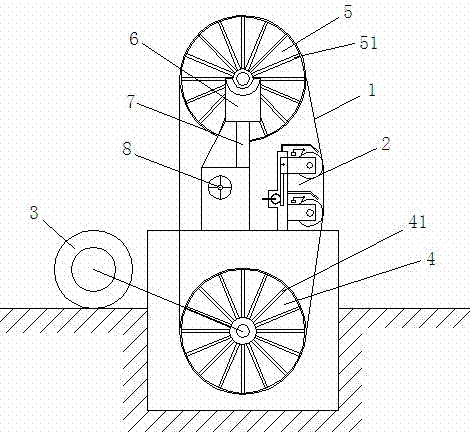

[0021] Such as figure 1 , figure 2 As shown, the present invention includes a saw blade 1, a saw blade transmission device and a saw blade positioning device 2 that abuts against the saw blade to make the cutting area of the saw blade in a vertical state. The saw blade transmission device includes a drive device 3 (motor), and a The driving wheel 4 and the driven wheel 5 located above the fuselage, the motor drives the driving wheel 4 through a V-belt (or chain), the saw blade 1 drives and connects the driving wheel 4 and the driven wheel 5, and the driving wheel 4 and the driven wheel 5 are respectively equipped with Support rod 41,51, driven wheel 5 below is provided with support holder 6, and support holder 6 below is connected with push rod 7, and push rod 7 below is provided with adjusting dial 8, can adjust push rod 7 to move up and down by adjusting rotating disc 8, plays the role of The effect of tensioning saw blade 1.

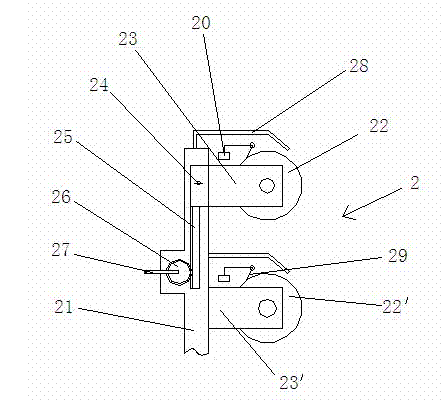

[0022] The saw blade positioning device 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com