Broaching fixture for key groove of connection fork sleeve

A technology for connecting fork sleeves and keyways, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of increased production cost, delayed production schedule, low processing efficiency, etc., to reduce production costs and labor. Strength, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

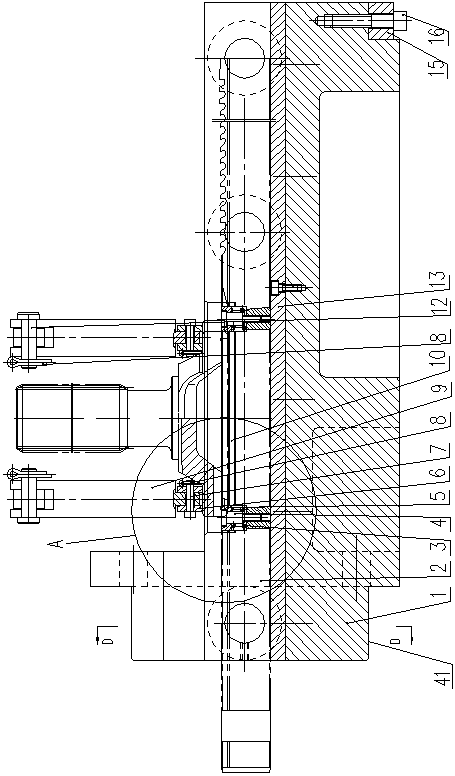

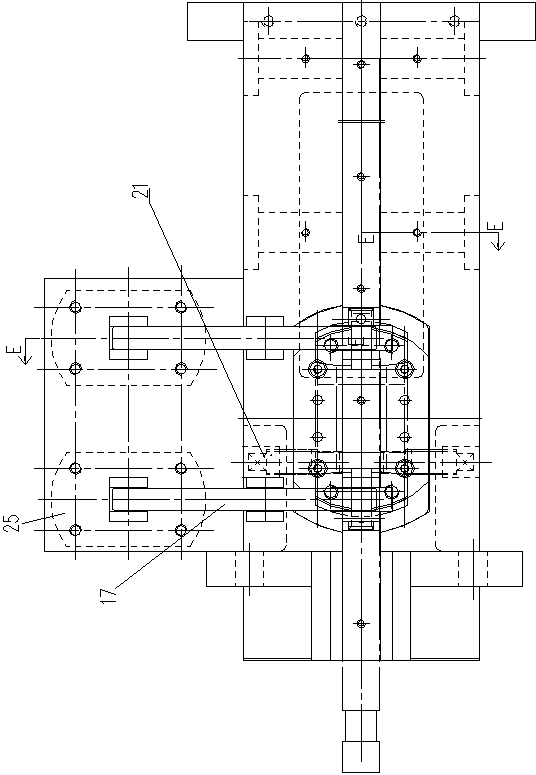

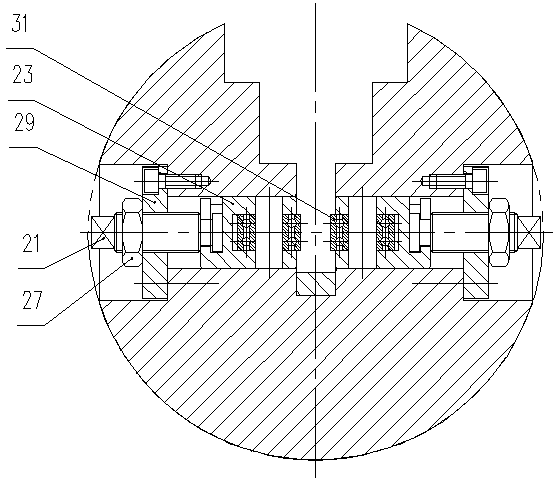

[0023] Such as Figure 1 to Figure 5 As shown, the jig for broaching the keyway of the yoke sleeve of the present invention includes a clamp body 1, the left end of the clamp body 1 is provided with a notch 41 compatible with the machine tool, the clamp body 1 is provided with a broach backing plate 13, and the broach pad The plate 13 is provided with a broach 2; the chuck body 1 is connected with a positioning disk 10 through a hexagon socket head screw, and the positioning disk 10 is used for positioning the outer circle and the end surface of the workpiece. The broach 2 passes through the positioning disc 10; the clamp body 1 is provided with a workpiece pressing device for pressing the workpiece. The bottom of the clamp body 1 on the other side of the notch 41 is provided with a support backing plate 15. When in use, one side of the clamp body 1 is connected to the machine tool through the notch 41, and the support pad 15 on the other side of the clamp body 1 passes throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com