Optical fiber pay-off device

A pay-off device and optical fiber technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve problems such as excessive attenuation, fiber breakage, and optical fiber damage, and achieve reduction of damage, elimination of sliding frictional resistance, The effect of reducing fiber breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Specific embodiments of the invention will be described in detail below in conjunction with the accompanying drawings.

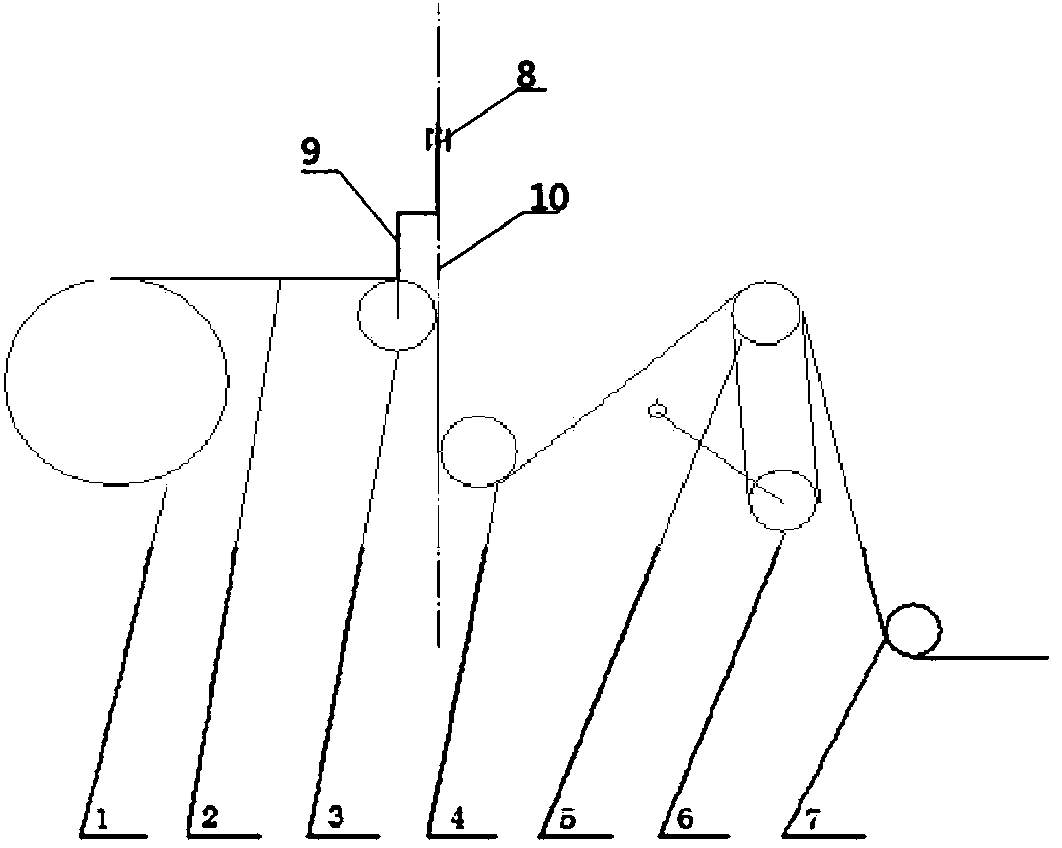

[0009] Such as figure 1 As shown in , the optical fiber 2 is released from the pay-off reel 1, and the optical fiber 2 is guided to the lower right positioning wheel 4 through the universal wheel 3, and then successively passes through the positioning wheel group 5 and the dancing wheel group 6 composed of two guide wheels , and finally enter the casing through the guide wheel 7. The universal wheel 3 is supported by a rotatable bracket 9 mounted on the top of the universal wheel 3. In order to allow the rotary bracket 9 to rotate freely, a bearing 8 is housed in the rotary bracket 9, so that the universal wheel 3 will follow the optical fiber 2 in unwrapping Disc 1 moves left and right and rotates to reduce friction; in order to further reduce friction, the center line 10 of the rotating shaft of the universal wheel support is tangent to the wheel g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com