Photoelectric 12 divisions drilling tools face angle drill following sensor

A photoelectric and sensor technology, applied in the field of sensors, can solve the problems of inability to perform testing while drilling, turbidity of drilling circulating fluid, impracticability of deep holes, etc., and achieve the effect of convenient secondary instrument interface, low cost and strong vibration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

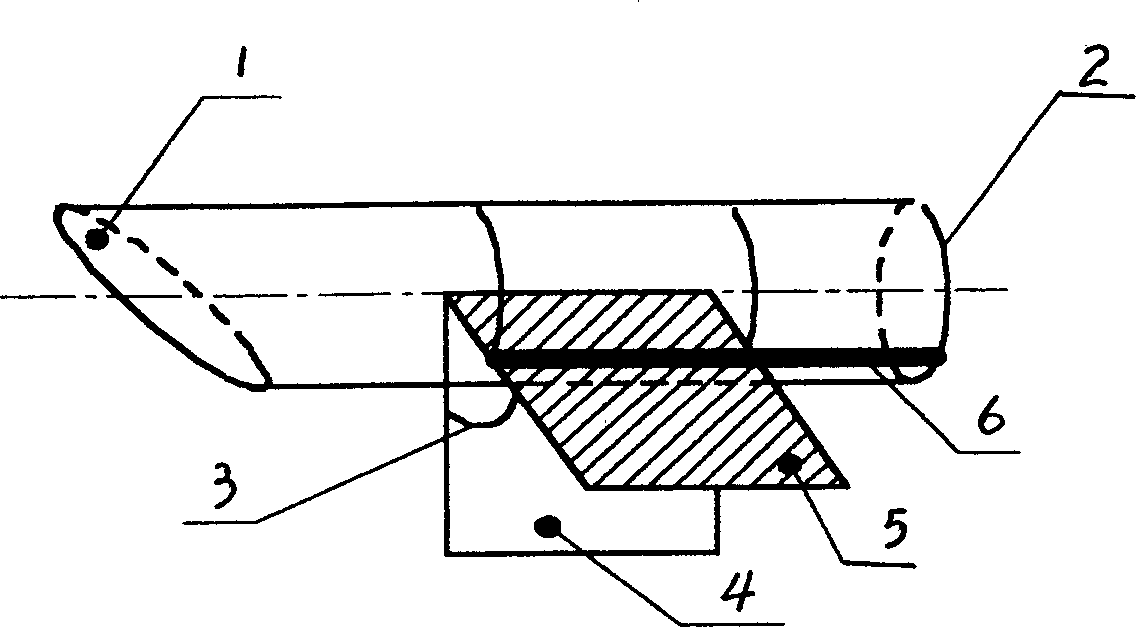

[0022] The invention aims at the key technical problem that the face angle of the drilling tool needs to be detected while drilling in the underground near-horizontal steering drilling project, and realizes the detection of the face angle of the drilling tool by adopting the method of combining the gravity rolling slider and the photoelectric effect. Due to the limitation of the diameter of the underground borehole, the sensor is required to be small in size and easy to install. In addition, it should be able to adapt to the environment of measurement while drilling (anti-vibration, etc.).

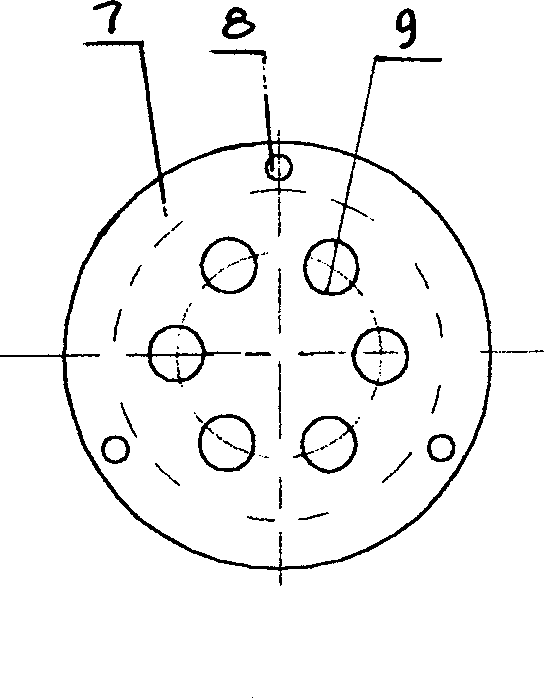

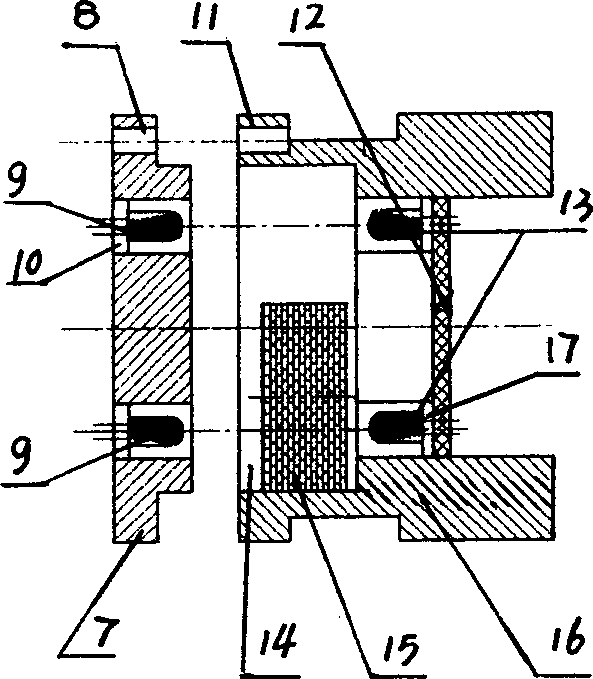

[0023] Such as figure 2 , image 3 , Figure 4 As shown, the photoelectric 12-degree indexing drilling tool face angle while drilling sensor, the front cover plate 7 is evenly arranged with 6 light-emitting holes 10 along the circumference, and the 6 infrared light-emitting tubes 9 are respectively located in the light-emitting holes 10; One side of the front cover 7 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com