Socket

A socket and socket hole technology, applied in the electrical field, can solve the problems of surface dust, dust or water droplets entering, causing harm, etc., and achieve the effect of preventing dust and dust and water from falling into

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

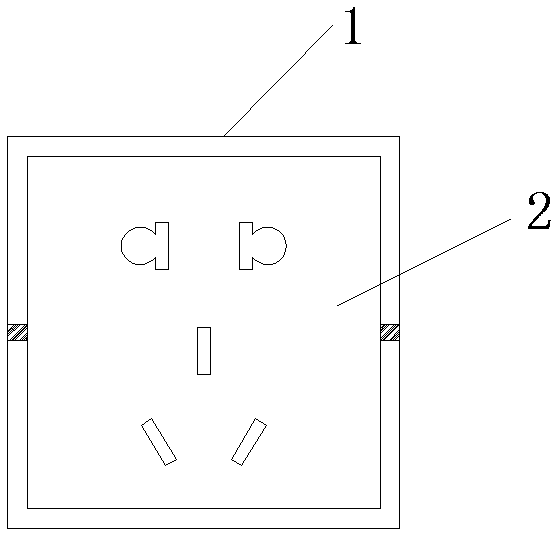

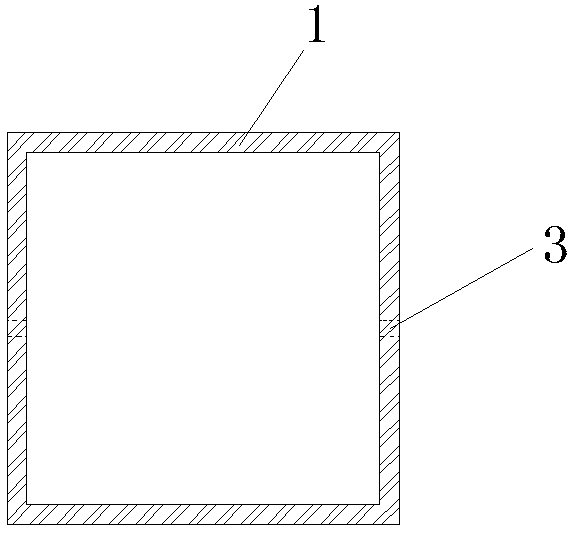

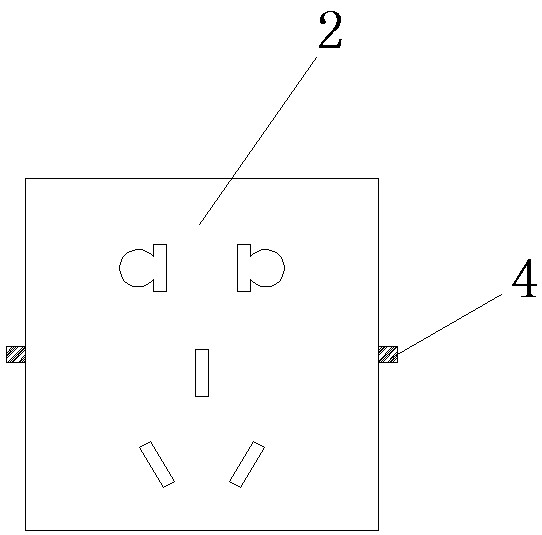

[0052] a socket such as figure 1 As shown, it includes the socket slot 1 and the socket body 2, the socket slot 1 and the socket body 2 are rotatably connected, and the socket slot 1 is a cube, such as Figure 4 As shown, the inner wall of socket groove 1 is provided with two relative shaft holes 3, and these two shaft holes 3 can be up and down, or left and right, as figure 2 In the schematic diagram shown, the shaft hole 3 is opened on the left and right, and the shaft hole 3 runs through the inner wall of the socket groove 1, image 3 Shown is a schematic diagram of the structure of the socket body 2. There are rotating shafts 4 on both sides of the socket body 2. The rotating shaft 4 is hollow. The rotating shaft hole 3 matches the rotating shaft 4. The setting of the hollow rotating shaft 4 can connect the wires. 15 passes through the hollow rotating shaft 4, and is electrically connected with the conductor in the socket hole, as Figure 15 As shown; when the plug need...

Embodiment 2

[0054] A socket, the same as Embodiment 1, the difference is that the socket groove 1 is hemispherical, and the socket body 2 is circular, such as Figure 5-8 shown.

Embodiment 3

[0056] Such as Figure 5-6As shown, the socket body 2 is provided with a card slot 6 around, and the dust-proof sheet 5 is arranged in the card slot 6, and the dust-proof sheet 5 is provided with a socket hole. When in use, connect the socket hole on the dust-proof sheet 5 with the socket body The socket holes on 2 correspond to each other, and then the plug can be plugged in. If the plug is not needed, the dust-proof sheet 5 can be rotated, so that dust is difficult to enter the socket; The design of 5 is not only suitable for the rotary connection between the socket slot 1 and the socket body 2, but also for the fixed connection commonly existing in the market, or other designs. In addition, the dust-proof sheet 5 can be replaced .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com