A thermal desorption device and method for soil remediation

A soil remediation and thermal desorption technology, applied in the restoration of polluted soil and other directions, can solve problems such as secondary pollution, achieve stable and uniform heating, reduce dioxin generation, and increase the intensity of combustion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings.

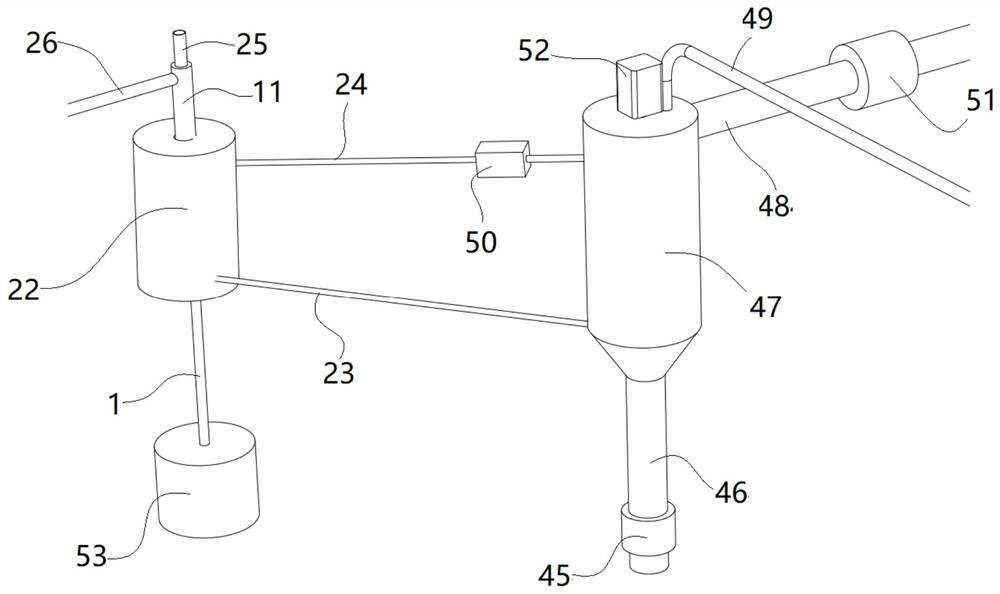

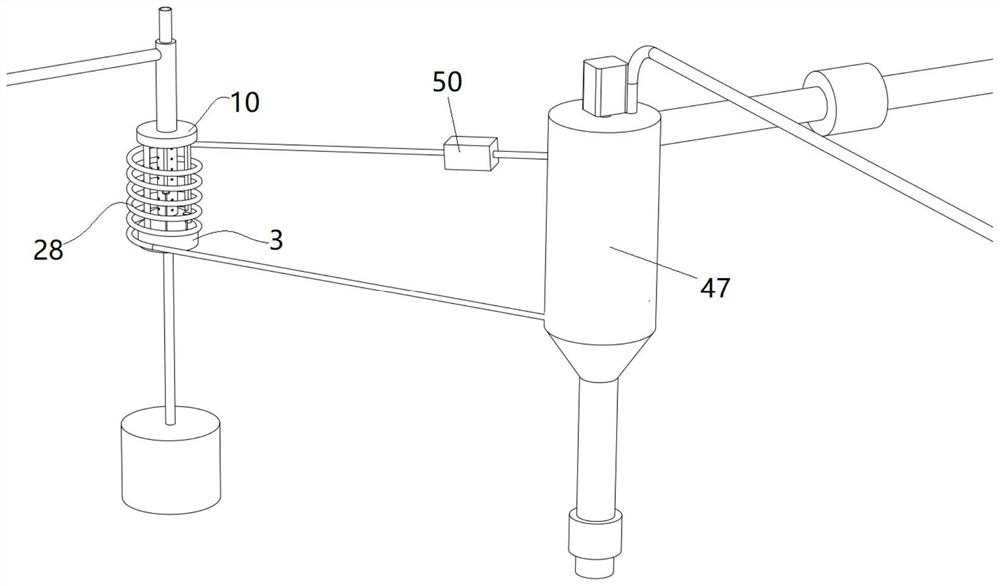

[0045] as attached Figures 1 to 11 Shown is a thermal desorption device for soil remediation, including a thermal oil heating furnace unit 22 and a thermal desorption unit 47;

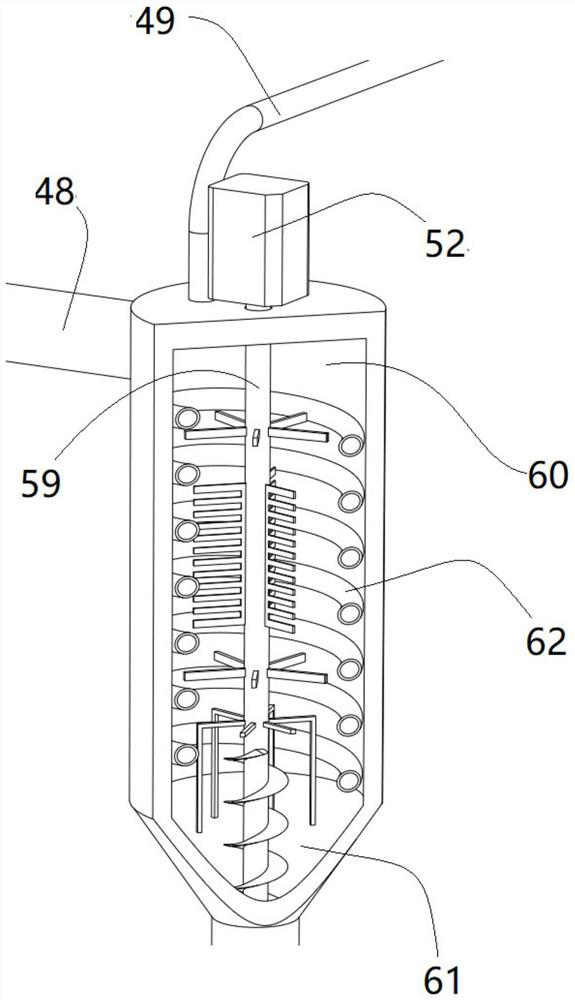

[0046] The heat-absorbing spiral tube 28 is arranged inside the thermal oil heating furnace unit 22; the heat-releasing spiral tube 62 is arranged inside the heat desorption unit 47; the hot oil outlet end of the heat-absorbing spiral tube 28 passes through the The oil pipe 23 is in communication with the hot oil inlet end of the heat releasing spiral tube 62; Communication connection; the second oil guide pipe 24 is provided with a circulation pump 50 .

[0047] The thermal desorption unit 47 has a cylindrical airtight container structure, the inner cavity of the thermal desorption unit 47 is a soil thermal desorption cavity 60, and the lower end of the soil thermal desorption cavity 60 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com