Method for achieving directional solidification based on 3D printing of multi-layer hollow shell mold

A 3D printing and directional solidification technology, applied in the direction of casting mold, core, casting mold composition, etc., can solve the problems of reducing casting performance, low cooling speed, affecting casting quality, etc., to improve casting pass rate, reduce miscellaneous crystals, The effect of optimizing the quality of castings and their properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The method for realizing directional solidification based on 3D printing multi-layer hollow shells according to the present invention will be described in detail below with reference to the accompanying drawings.

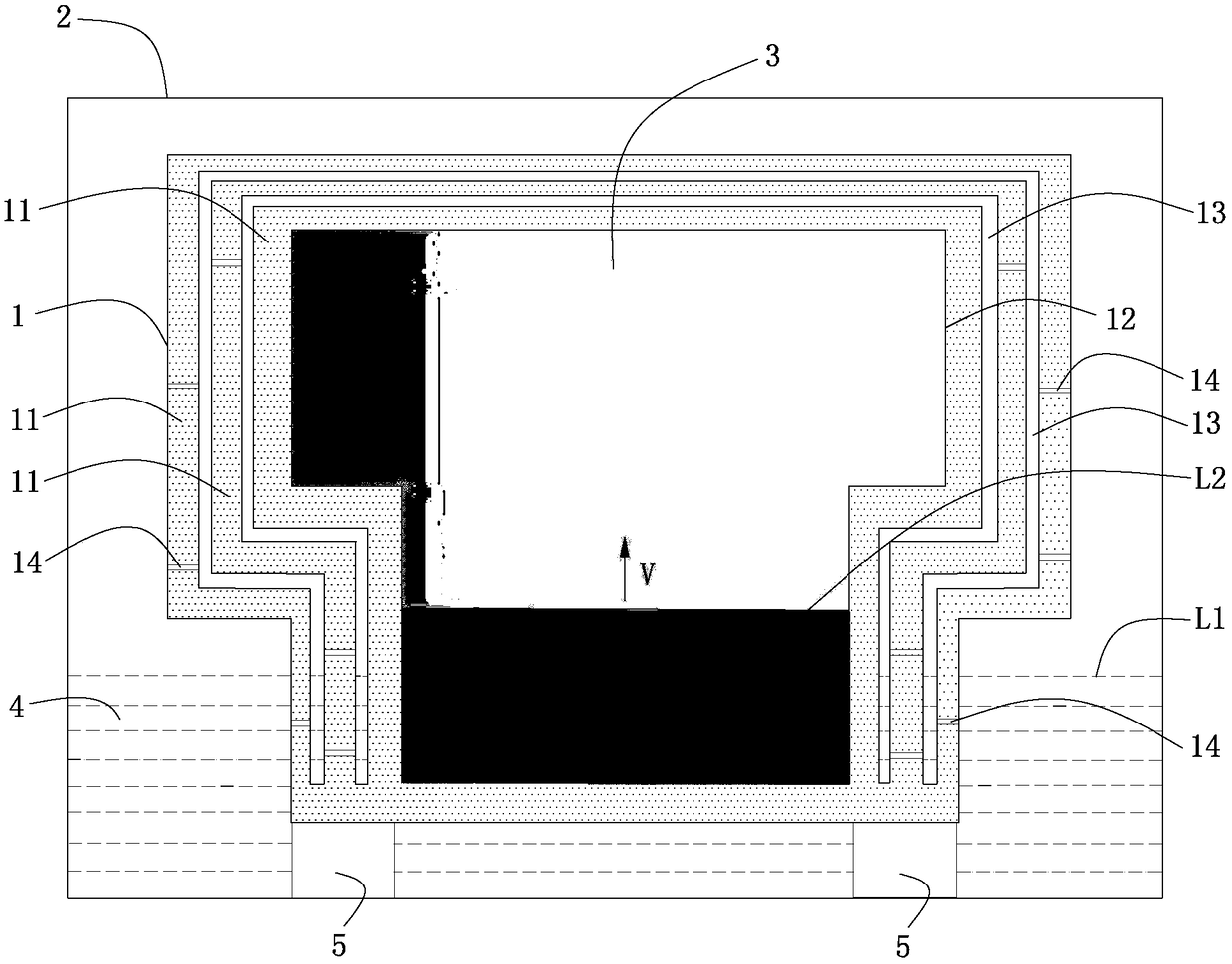

[0015] refer to figure 1 , according to the method for realizing directional solidification based on 3D printing multilayer hollow shell mold of the present invention, comprising step: S1, according to the casting to be cast, obtain the multilayer hollow shell mold structure 1 as the mold based on 3D printing technology, so The multi-layer hollow shell structure 1 includes a plurality of nested shells 11, the innermost shell 11 forms a cavity 12, and a hollow layer 13 is formed between two adjacent shells 11, except for the innermost Other shells 11 outside the shell are all provided with a plurality of through holes 14 evenly distributed in the vertical direction for communicating with the hollow layer 13; S2, the multilayer hollow shell structure 1 obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com