Multi-sided laser marking fixture

A surface laser and fixture technology, applied in the field of multi-surface laser marking fixtures, can solve problems such as complex operation, affecting marking efficiency and marking position, and failing to meet people's marking needs, achieving low cost and convenient operation , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

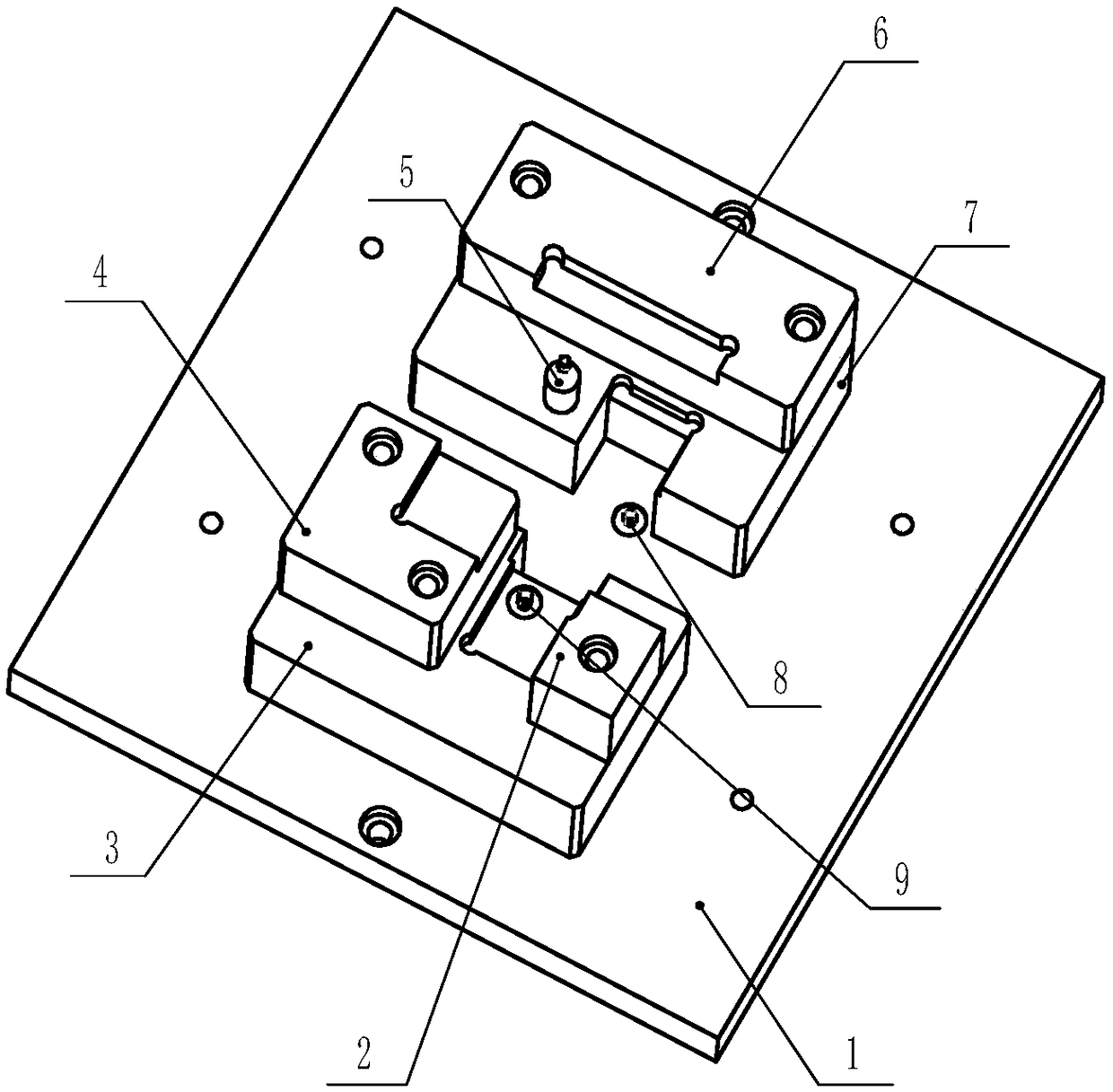

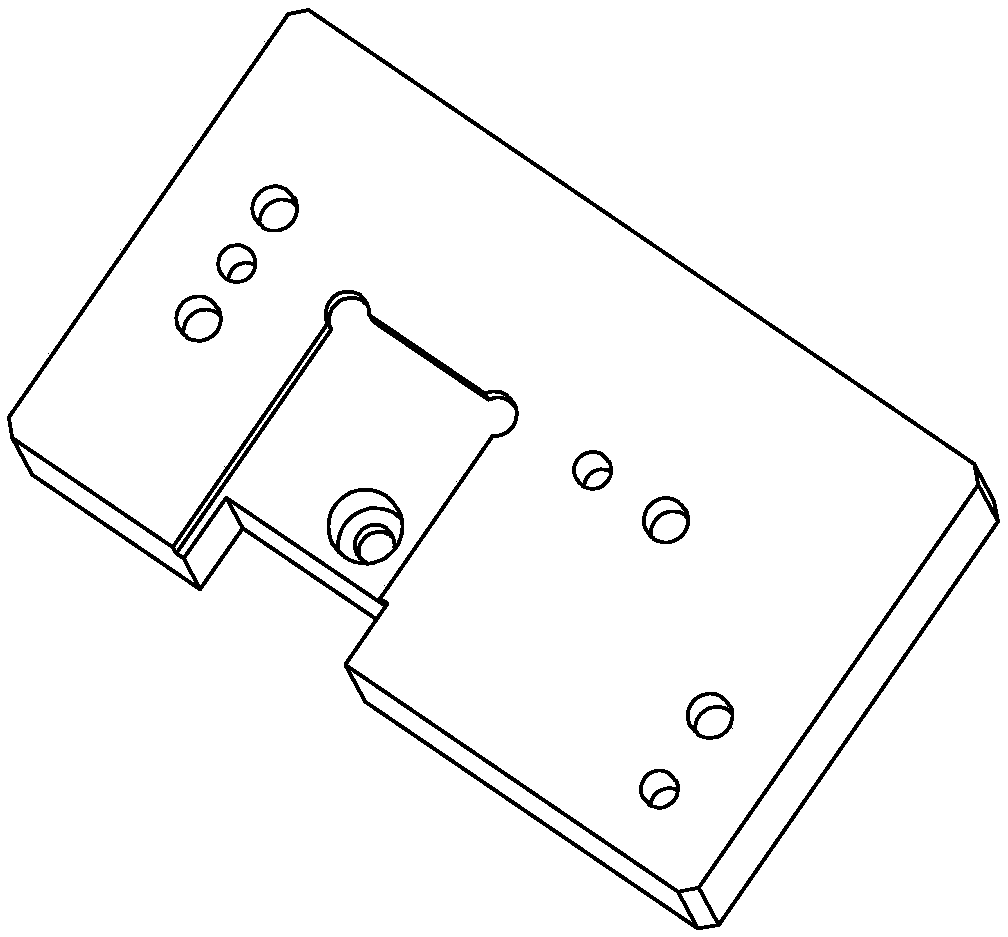

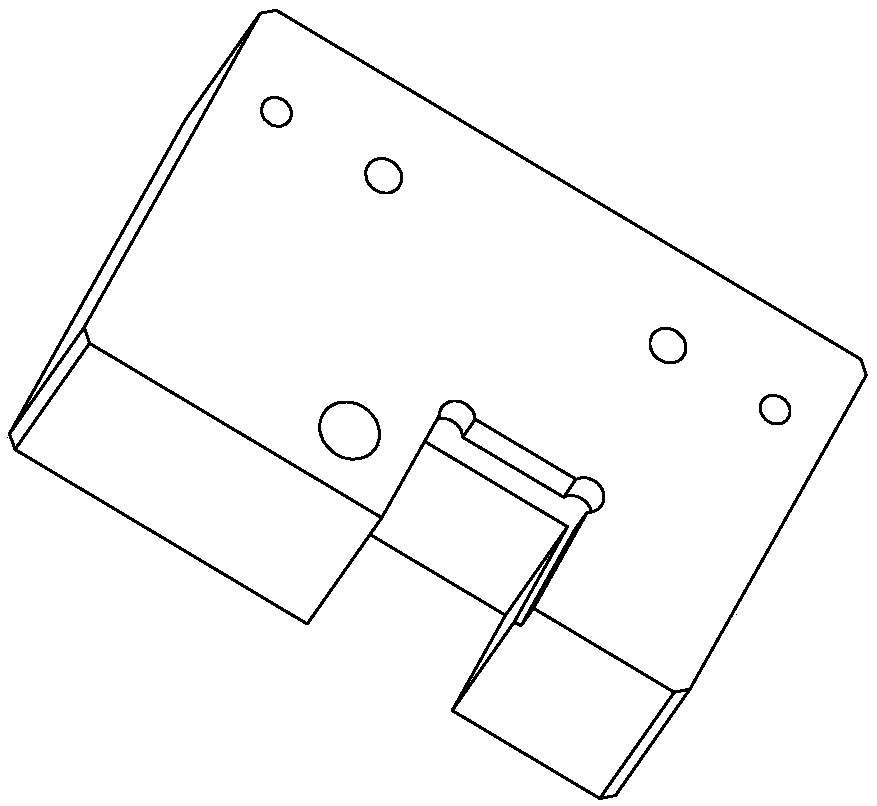

[0022] A multi-faceted laser marking fixture, including a bottom plate 1, a fifth positioning block 2, a first positioning block 3, a fourth positioning block 4, a third error prevention pin 5, a third positioning block 6, and a second positioning block 7 , the second anti-error pin 8 and the first anti-error pin 9, the first positioning block 3 is fixed on the top surface of the bottom plate 1 by screws and the first positioning block 3 is close to the front side of the bottom plate 1, the described The first positioning block 3 is provided with a rectangular groove, and the second positioning block 7 is fixedly installed on the top surface of the base plate 1 by screws and the second positioning block 7 is close to the rear side of the base plate 1. The second positioning block The block 7 is provided with a rectangular groove, the second anti-error ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com