Wide-width surface overturning laser marking machine

A laser marking machine and flip technology, applied in typewriters, printing and other directions, can solve the problems of small marking range, inability to achieve large-scale, wide-format laser marking, and inability to achieve multiple anti-counterfeiting of finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

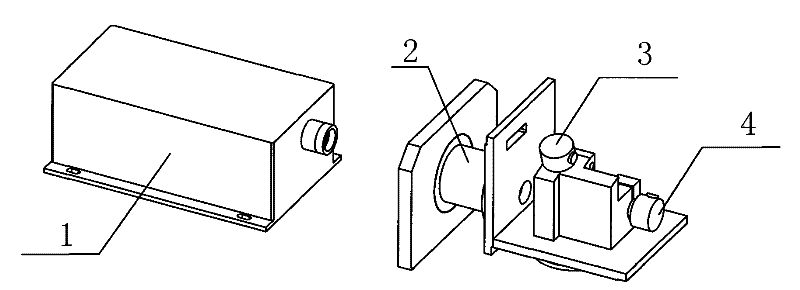

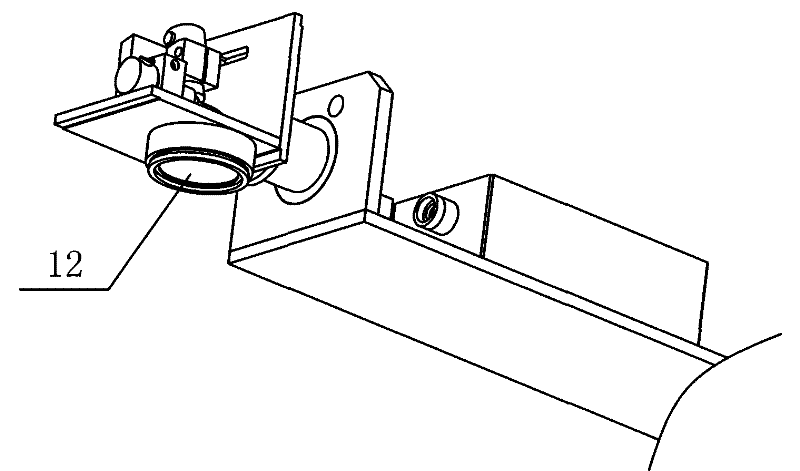

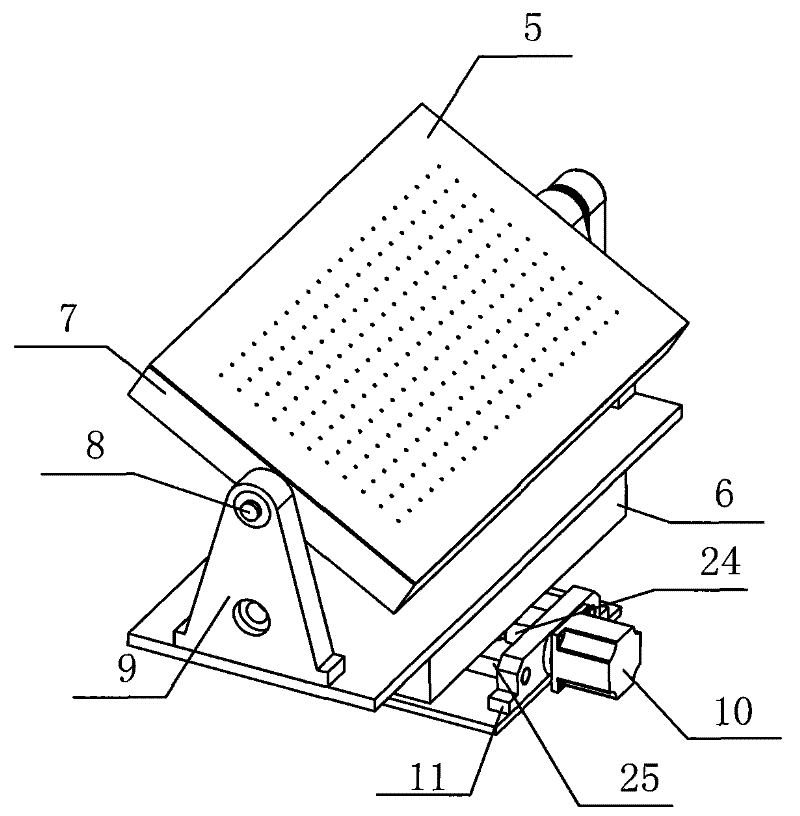

[0033] Such as Figure 1~4 The wide-format reversible laser marking machine shown includes a laser marking machine body and laser components. The laser component is installed on the laser marking machine body. Its special feature is that one end of the laser component is equipped with a reflective focusing The device 12 is equipped with a wide-format turning device on the working surface of the laser marking machine body facing the reflective focusing device 12 . In simple terms, the wide-format turning device includes a two-dimensional mobile worktable, and an axial turning mechanism is installed on the front of the workbench.

[0034] further combined figure 1 , figure 2 From the point of view, the laser component includes a laser resonator 1, the working end of the laser resonator 1 is provided with a beam expander 2, and one side of the working end of the beam expander 2 is distributed with an X vibrating mirror 3 and a Y vibrating mirror 4, and a Y vibrating mirror 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com