Plastic bottle laser marking system and method based on machine vision

A laser marking method and machine vision technology, applied in the field of visual laser marking, can solve the problems of one-time marking of difficult workpieces, unfavorable simultaneous positioning of multiple workpieces, and low safety, so as to improve marking accuracy and reliability. Reproducibility and the effect of improving marking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

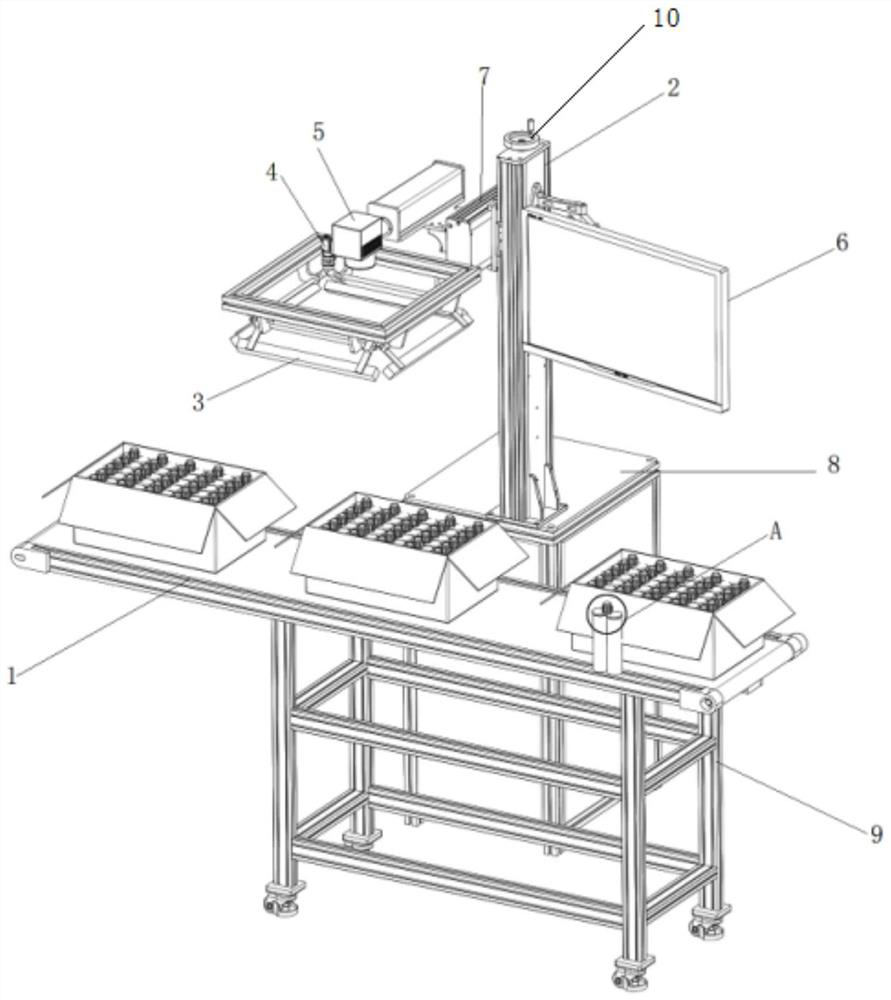

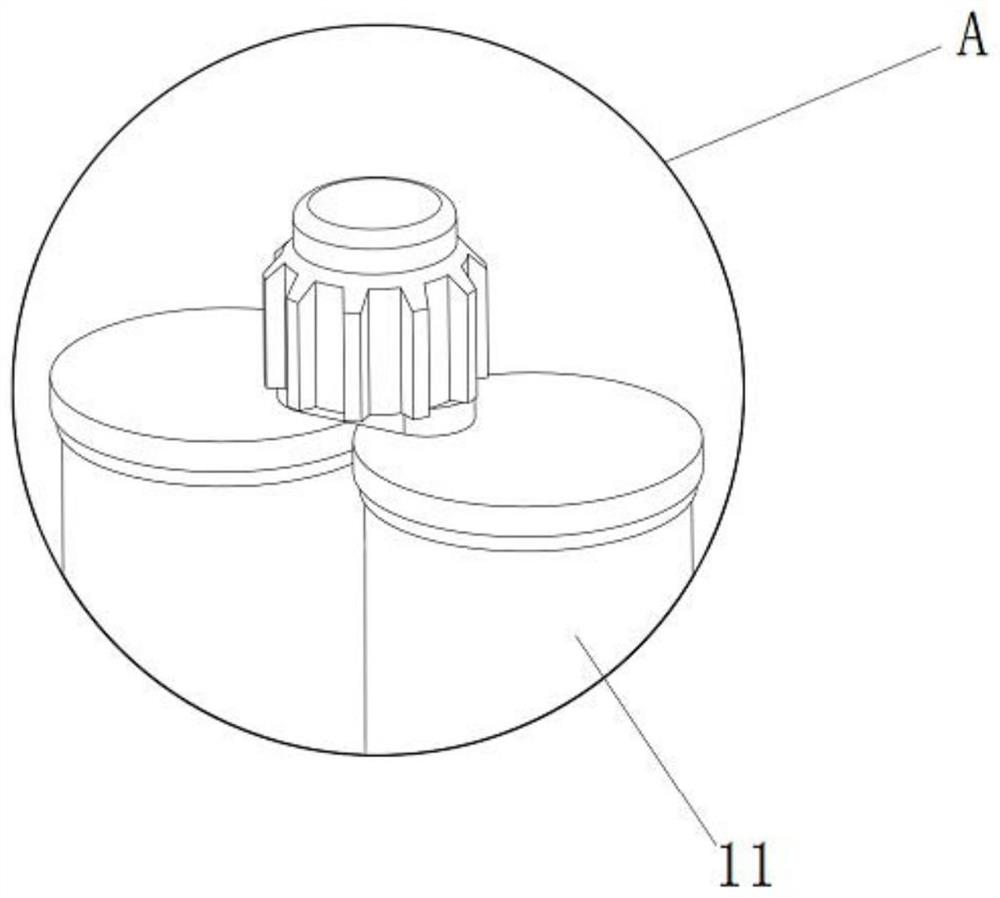

[0042] Such as Figure 1~6 As shown, the embodiment of the present invention provides a laser marking system for plastic bottles based on machine vision, including a transmission mechanism and a marking machine mechanism, the transmission mechanism includes a fixed frame 9 and a conveyor belt 1 installed on the fixed frame 9, marking The mechanism 5 is set up on the side of the conveyor belt 1, and the marking mechanism 5 is used to mark the plastic bottles on the conveyor belt 1.

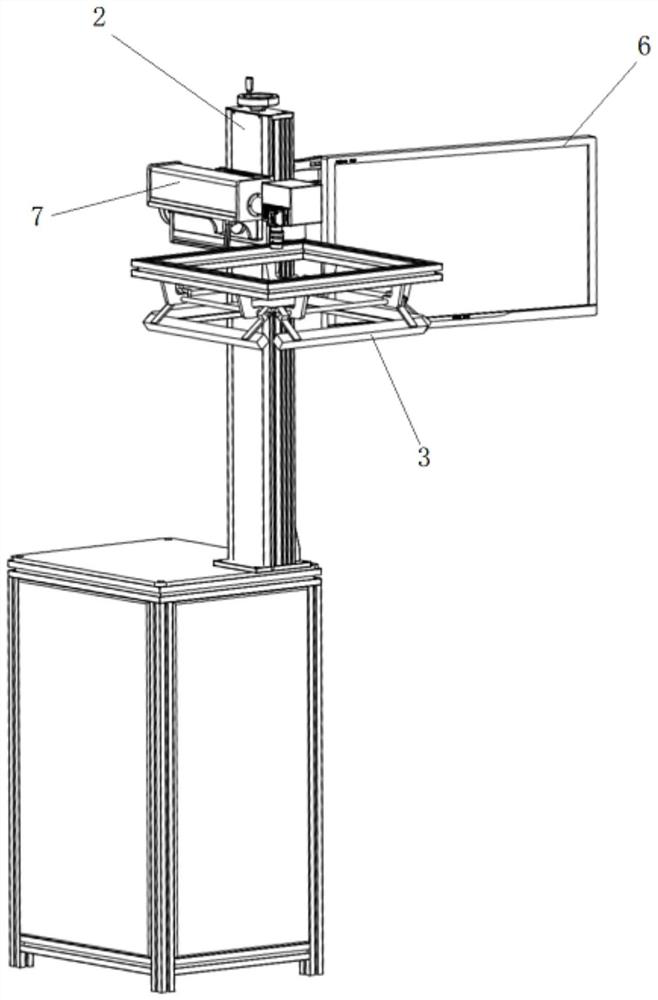

[0043] In this specific embodiment, the marking machine 5 mechanism includes a fixed table 8, a vertical support 2, a horizontal support 7, a micro industrial computer 6 and a visual positioning marking module, and the vertical support 2 is erected on the upper surface of the fixed table 8. One side of the straight support 2 can be slidably installed with a horizontal support 7, and the other side is equipped with a micro industrial computer 6; Straight bracket 2.

[0044] In this specific embodi...

Embodiment 2

[0060] Such as Figure 7 As shown, in order to better adjust the position of the visual positioning marking module, the present embodiment installs the vertical support 2 on the plane support 13 by setting the plane support on the fixed table 8, and then the corresponding plane support 13 can Adjust to adapt to the position of the entire marking mechanism corresponding to the transmission mechanism, so that the entire module has better adaptability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com