A kind of laser marking method of capsule

A laser marking method and capsule technology, applied in typewriters, printing, etc., can solve problems such as inability to process laser marking and difficult implementation, and achieve the effect of large-scale industrial production and laser marking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

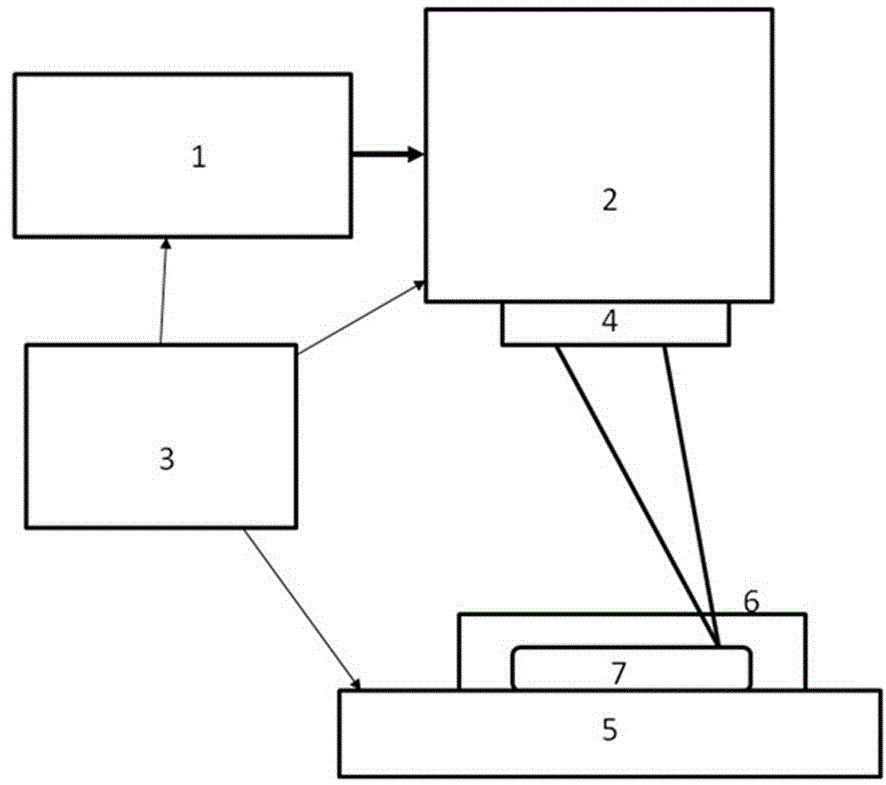

[0024] Embodiment one: see attached figure 1 As shown, a capsule laser marking method, capsules, such as medical material capsules, are encapsulated by a transparent or translucent packaging layer and fixed on a multi-dimensional processing platform 5 to wait for marking processing. The specific connection relationship is as follows: 2 micron nanosecond pulse The nanosecond pulsed laser beam output by the fiber laser 1 enters the high-speed laser scanning galvanometer 2 after laser collimation and beam expansion; the laser beam entering the high-speed laser scanning galvanometer 2 is controlled by the marking machine controller 3 to realize The high-speed movement of the beam on the surface of the capsule processing part 7 realizes the laser marking process; the laser beam passing through the high-speed laser scanning galvanometer 2 enters the 2-micron flat field mirror 4, and realizes that the laser beam is focused on the surface of the capsule processing part 7, and the 2-mic...

Embodiment 2

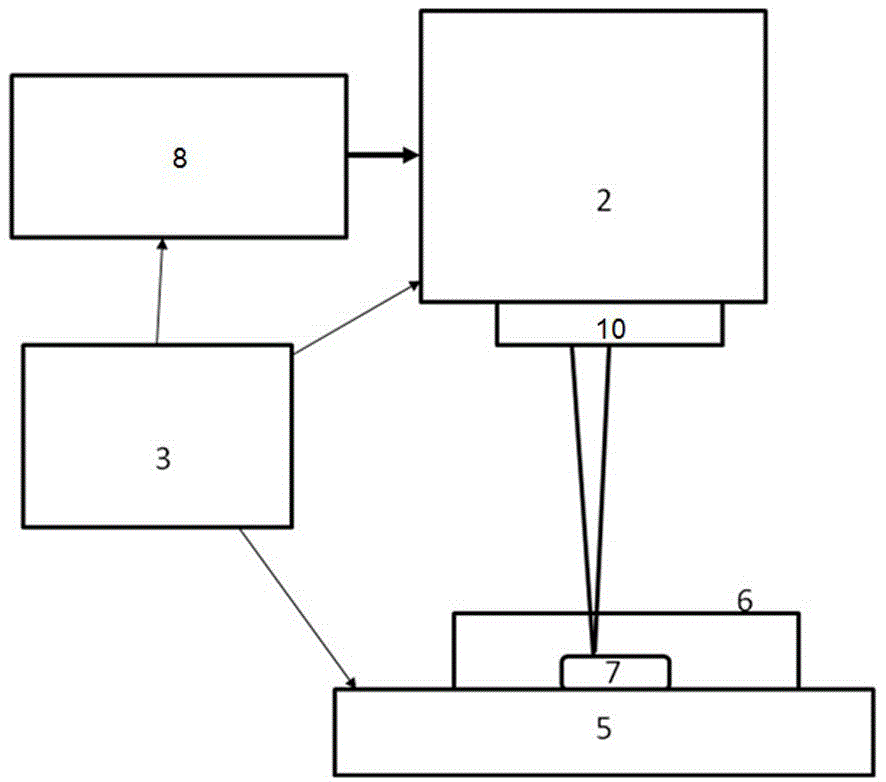

[0025] Embodiment two: see attached figure 2 As shown, a capsule laser marking method, capsules, such as medical material capsules, are encapsulated by a transparent or translucent packaging layer and fixed on a multi-dimensional processing platform 5 to wait for laser marking processing. The specific connection relationship is as follows: 2 microns microseconds The microsecond pulsed laser beam output by the pulsed fiber laser 8 enters the high-speed laser scanning galvanometer 2 after laser collimation and beam expansion; the laser beam entering the high-speed laser scanning galvanometer 2 is realized under the control of the marking machine controller 3 The high-speed movement of the laser beam on the surface of the capsule processing part 7 realizes the marking process of the laser; the laser beam passing through the high-speed laser scanning galvanometer 2 enters the 2-micron telecentric focusing field lens 10, and this 2-micron telecentric focusing field lens can be In ...

Embodiment 3

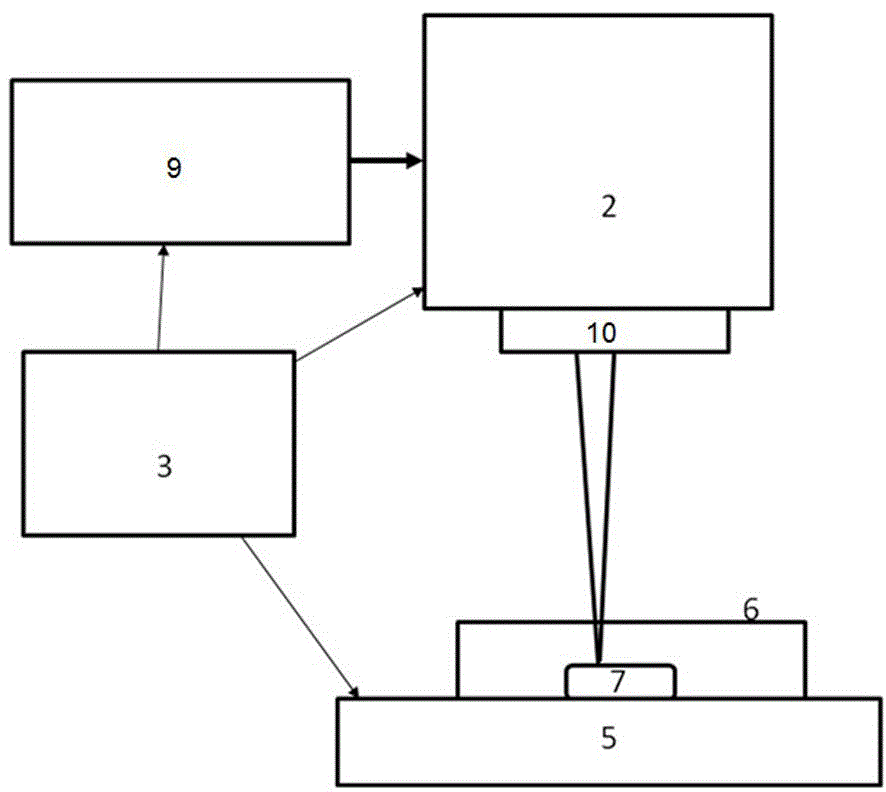

[0026] Embodiment three: see attached image 3As shown, a capsule laser marking method, capsules such as medical material capsules are encapsulated by a transparent or translucent packaging layer and fixed on a multi-dimensional processing platform 5 to wait for laser marking processing. The specific connection relationship is as follows: 2 micron millisecond pulse The millisecond pulsed laser beam output by the fiber laser 9 enters the high-speed laser scanning galvanometer 2 after laser collimation and beam expansion; the laser beam entering the high-speed laser scanning galvanometer 2 is controlled by the marking machine controller 3 to realize The high-speed movement on the surface of the capsule processing part 7 realizes the marking process of the laser; the laser beam passing through the high-speed laser scanning galvanometer 2 enters the 2-micron telecentric focusing field lens 10, and this 2-micron telecentric focusing field lens can be used throughout the processing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com