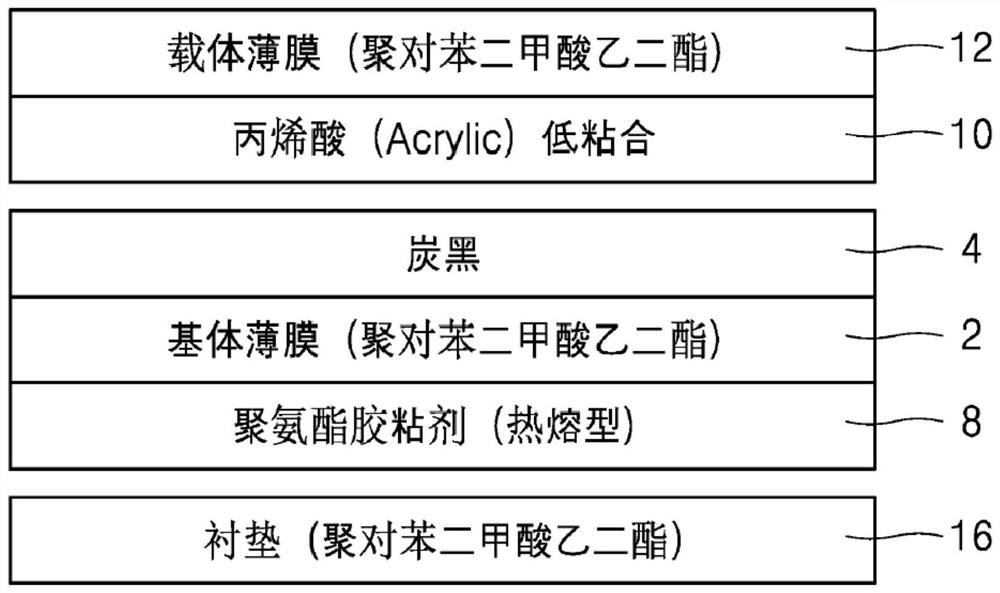

Wafer level backside adhesive tape, and manufacturing method therefor

A wafer-level, back-side technology, applied in semiconductor/solid-state device manufacturing, adhesives, adhesive types, etc., can solve problems such as cracks, improper sawing lines, and product detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

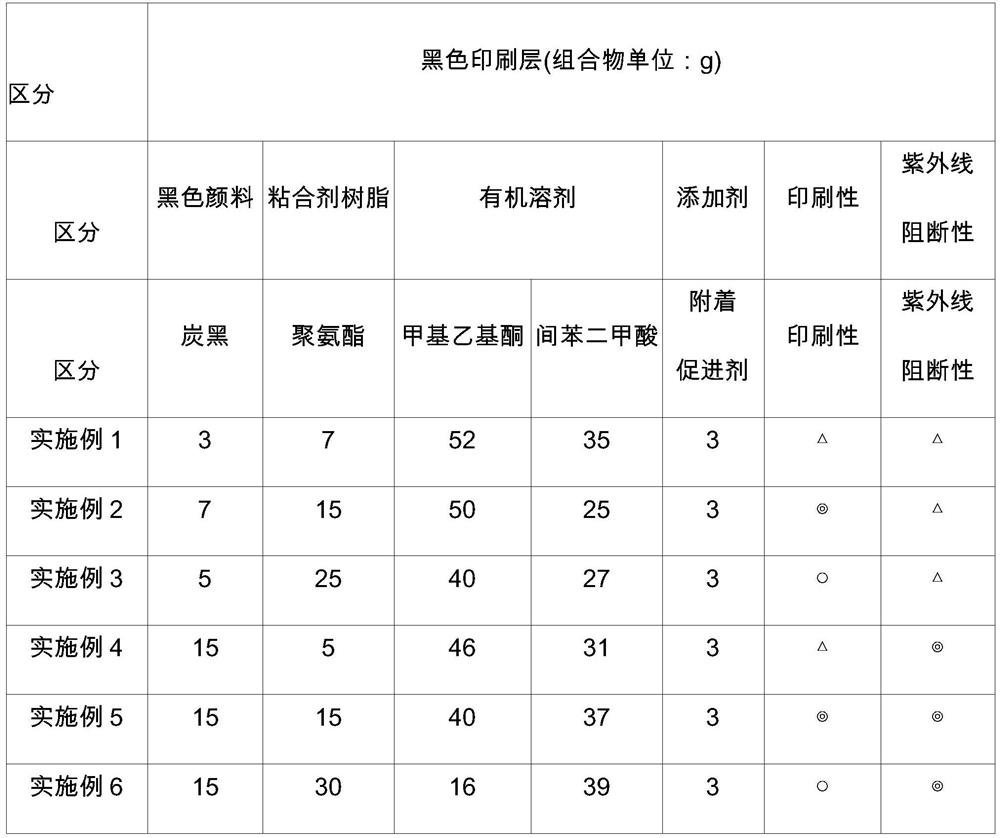

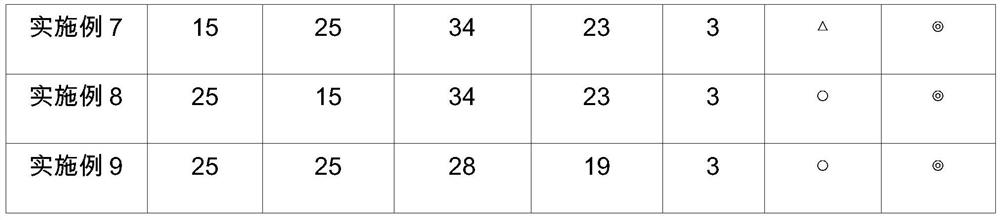

Examples

Embodiment 1

[0083] A PET film obtained by corona-treating one side surface of a PET film with a thickness of about 12 μm that was primer-coated with a thermosetting acrylic coating agent was prepared.

[0084] Thereafter, a black printing layer coating liquid of 5 g of carbon black, 15 g of polyurethane resin, 77 g of an organic solvent consisting of 52 g of methyl ethyl ketone and 25 g of isopropyl alcohol, and 3 g of adhesion promoter BYK-4500 was mixed using the gravure printing method A PET film having a black printed layer having a thickness of about 3.5 μm was formed by coating on one side surface of the corona-treated PET film.

Embodiment 2

[0086] A PET film obtained by corona-treating one side surface of a PET film with a thickness of about 12 μm that was primer-coated with a thermosetting acrylic coating agent was prepared.

[0087] Thereafter, a black printing layer coating solution that mixed 7 g of carbon black, 15 g of polyurethane resin, 75 g of an organic solvent consisting of 50 g of methyl ethyl ketone and 25 g of isopropyl alcohol, and 3 g of adhesion promoter BYK-4500 was mixed using the gravure printing method A PET film having a black printing layer having a thickness of about 3.5 μm was formed by coating on one side surface of the corona-treated PET film.

Embodiment 3

[0089] A PET film obtained by corona-treating one side surface of a PET film with a thickness of about 12 μm that was primer-coated with a thermosetting acrylic coating agent was prepared.

[0090] Thereafter, a black printing layer coating liquid that mixed 5 g of carbon black, 25 g of polyurethane resin, 67 g of an organic solvent consisting of 40 g of methyl ethyl ketone and 27 g of isopropyl alcohol, and 3 g of adhesion promoter BYK-4500 was mixed using the gravure printing method A PET film having a black printing layer having a thickness of about 3.5 μm was formed by coating on one side surface of the corona-treated PET film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com