Laser mark printing device for section steel

A laser marking and section steel technology, applied in the field of laser marking, can solve the problems of section steel marking and positioning and difficult to achieve assembly line operation, and achieve the effect of realizing assembly line operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

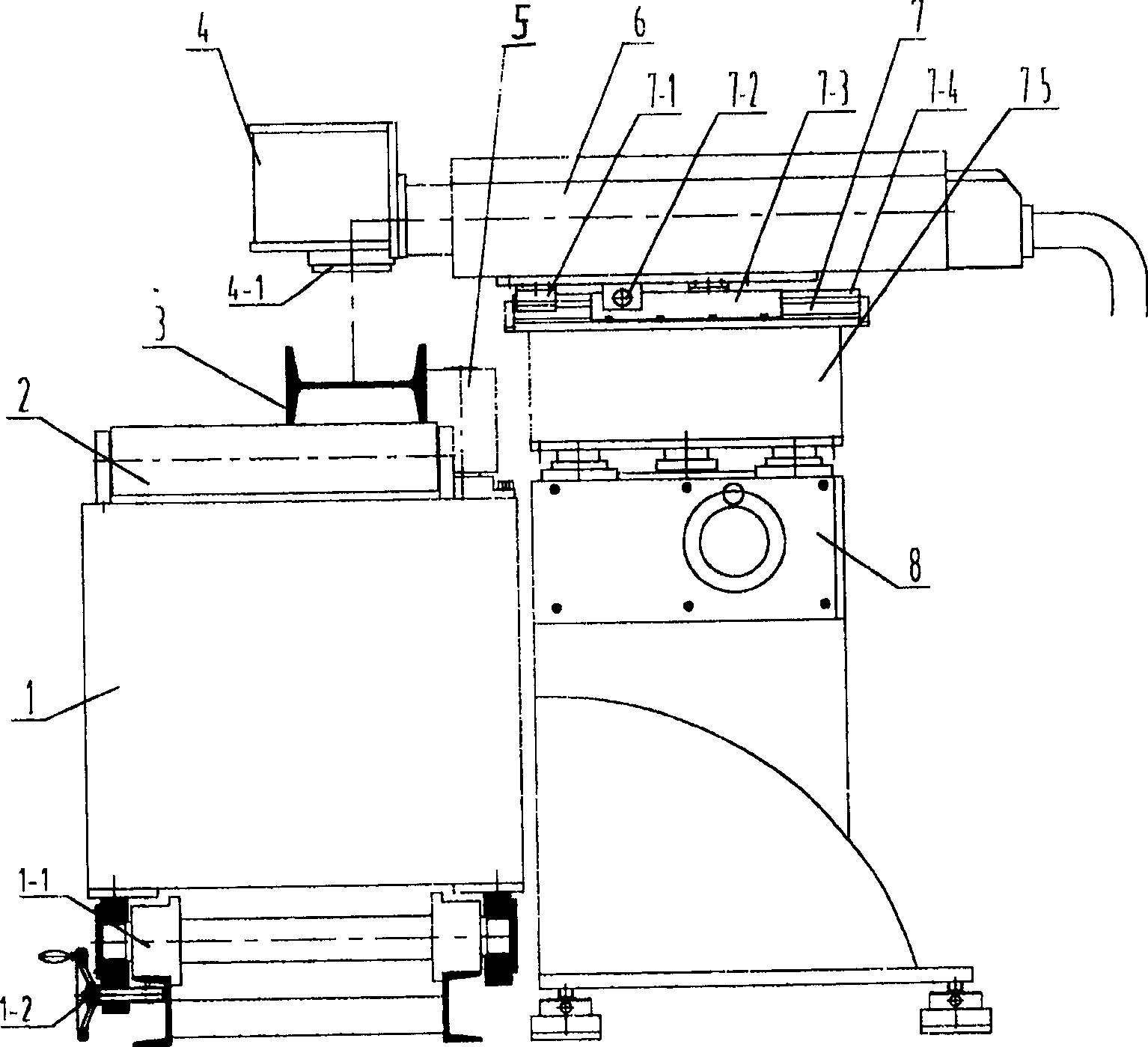

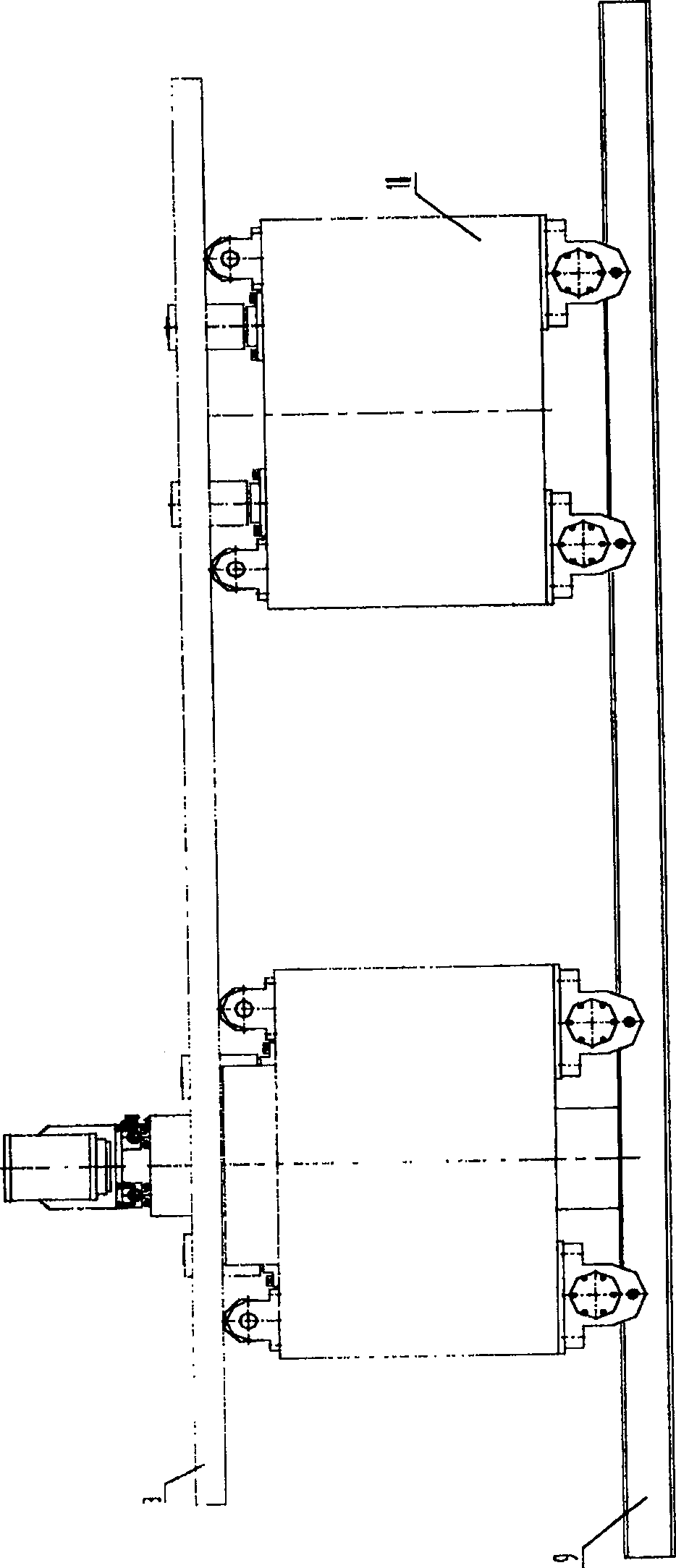

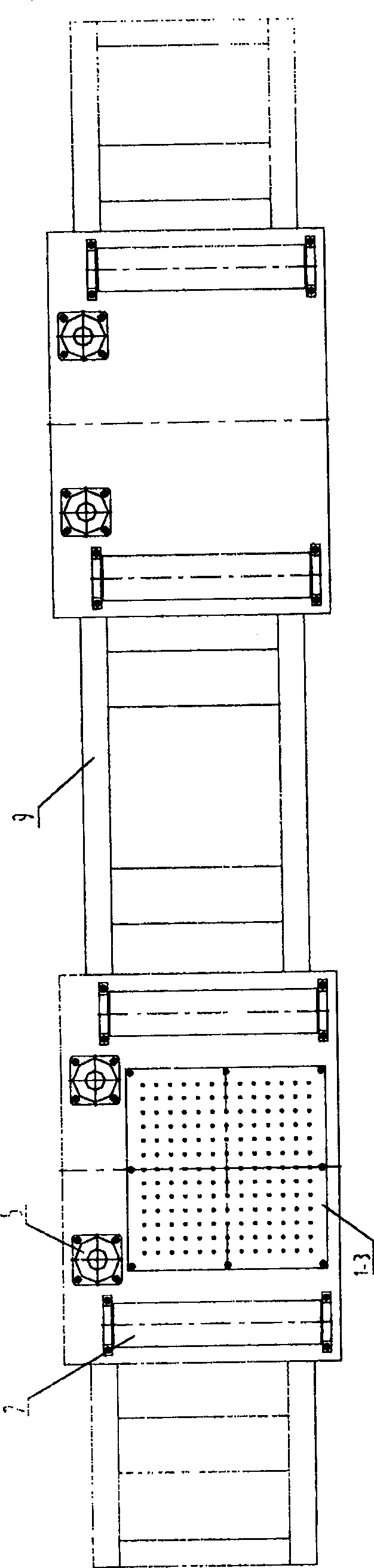

[0025] see figure 1 , figure 2 , the main components of the present invention are main workbench trolley 1, trolley wheels 1-1, trolley brake hand wheel 1-2, horizontal roller 2 for placing workpieces, workpieces waiting to be marked 3, two-dimensional scanning head 4, optical flat-field mirror 4-1. Vertical roller 5 for workpiece limit, laser 6, laser X-direction precision sliding table 7, laser Y-direction precision lifting mechanism 8, working trolley guide rail 9, driven working trolley 10.

[0026] see figure 1 , figure 2 , place the workpiece 3 on the main workbench trolley 1 and the driven work trolley 10, figure 1 The workpiece 3 in is an I-beam shown, and of course it can be other shaped steel, such as angle steel and channel steel. The workpiece 3 can roll on the horizontal roller 2. There are 2 pairs of horizontal rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com