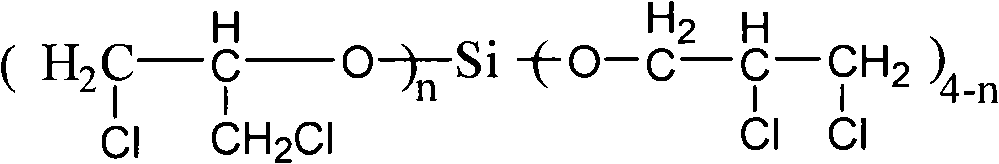

Silicic acid tetra (dichloropropyl) ester compound and preparation method thereof

A synergistic technology of epichlorohydrin and silicon halide, applied in the direction of silicon organic compounds, etc., to achieve good application prospects, small investment and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

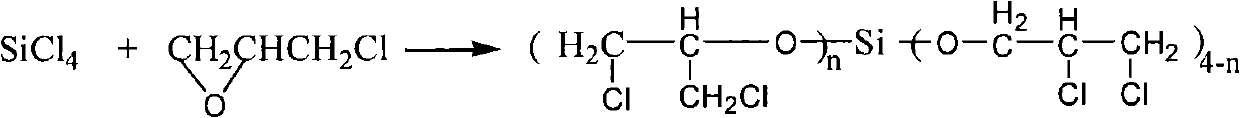

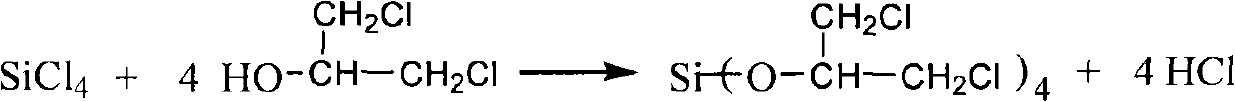

Method used

Image

Examples

preparation example 1

[0040] Preparation Example 1 In a 250ml four-neck flask equipped with a stirrer and a drying tube, nitrogen protection was introduced, 0.80mol of epichlorohydrin was added, stirred, and the initial temperature was 25° C. The reaction is carried out and the temperature is gradually increased), and then the temperature is slowly raised to 50 ° C. After maintaining the temperature for 8 hours, the excess reactant is distilled off, cooled, and the liquid obtained by filtering is tetrakis (dichloropropyl) silicate. The yield is 93%, the decomposition temperature is 267±5°C, and the flash point (open cup) is 260±5°C. The degree of Baume is 45.53 (14°C), the density is 1.455 (14°C), and the refractive index is n D 20 = 1.4966.

preparation example 2

[0041] Preparation Example 2 In a 250ml four-necked flask equipped with a stirrer and a drying tube, pass through nitrogen protection, add 0.6mol of epichlorohydrin, stir, and start to drop 0.10mol of silicon tetrachloride at an initial temperature of 25°C (with The reaction is carried out and the temperature is gradually increased), and then the temperature is slowly raised to 70 ° C. After maintaining the temperature for 6 hours, the excess reactant is distilled off, cooled, and the liquid obtained by filtering is tetrakis (dichloropropyl) silicate. The yield is 95%, the decomposition temperature is 267±5°C, and the flash point (open cup) is 260±5°C. The degree of Baume is 45.53 (14°C), the density is 1.455 (14°C), and the refractive index is n D 20 = 1.4966.

preparation example 3

[0042] Preparation Example 3 In a 250ml three-neck flask equipped with a stirrer and a drying tube, feed nitrogen protection, add 0.50mol of epichlorohydrin, stir, and start to drop 0.10mol of silicon tetrachloride (with the reaction Gradually increase the temperature), then slowly heat up to 90°C, and after maintaining the temperature for 4 hours, distill off the excess reactant, cool, and filter the resulting liquid to be tetra(dichloropropyl)silicate, with a yield of 95 %, the decomposition temperature is 267±5°C, and the flash point (open cup) is 260±5°C. The degree of Baume is 45.53 (14°C), the density is 1.455 (14°C), and the refractive index is n D 20 =1.4966

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com