Clamp facilitating slope machining of mold

A technology of inclined planes and fixtures, applied in metal processing equipment, metal processing machinery parts, clamping, etc., can solve the problems of inconvenient work, troublesome adjustment of overload, inconvenient adjustment of the demoulding slope, etc., and achieve the effect of increasing the demoulding slope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

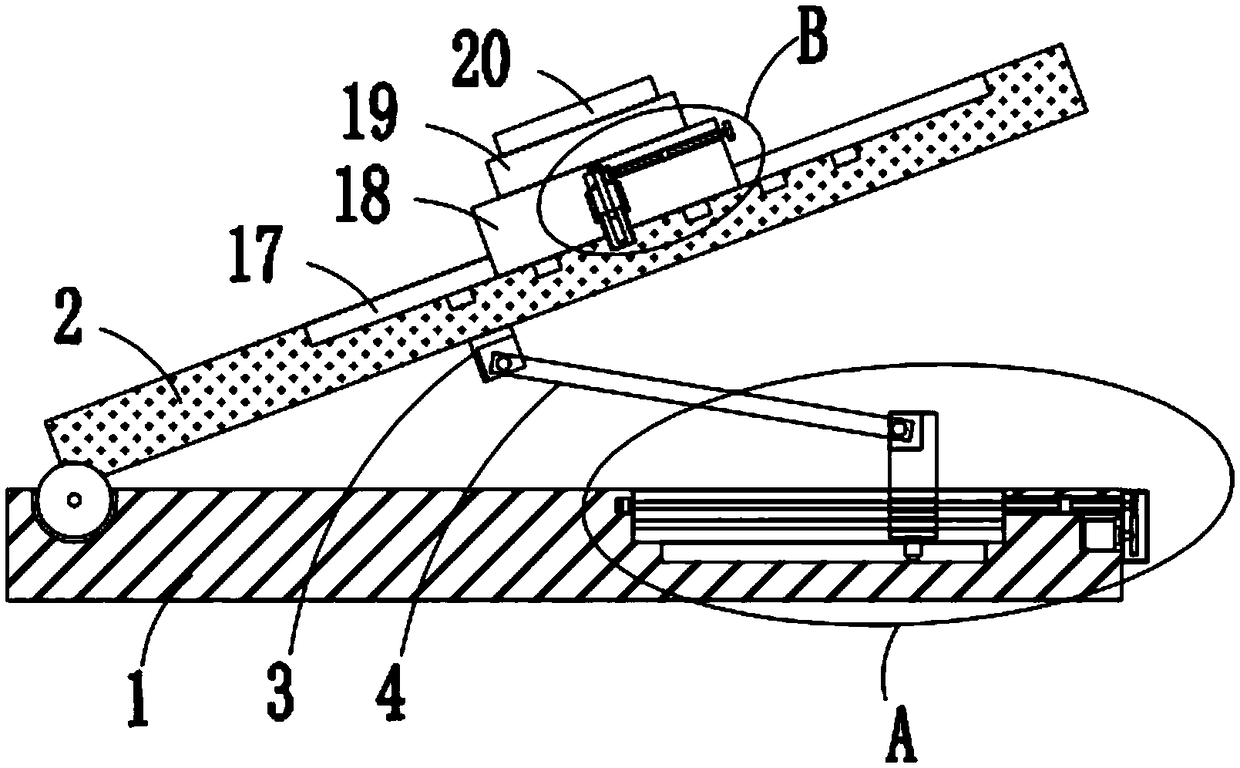

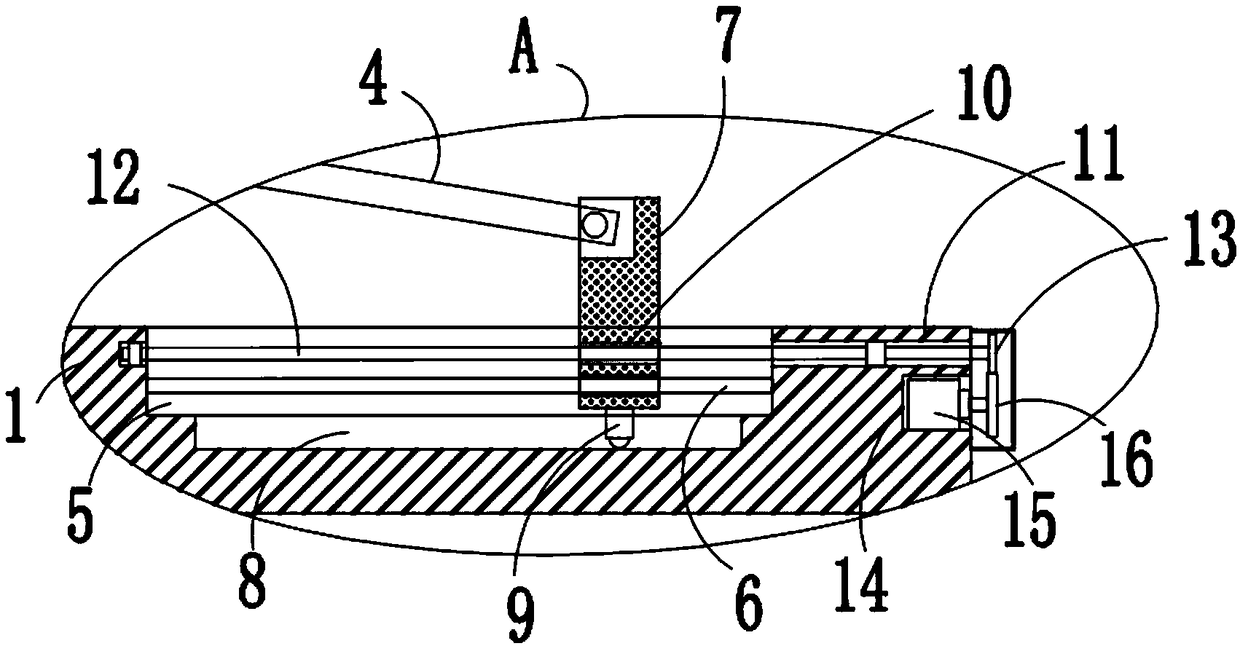

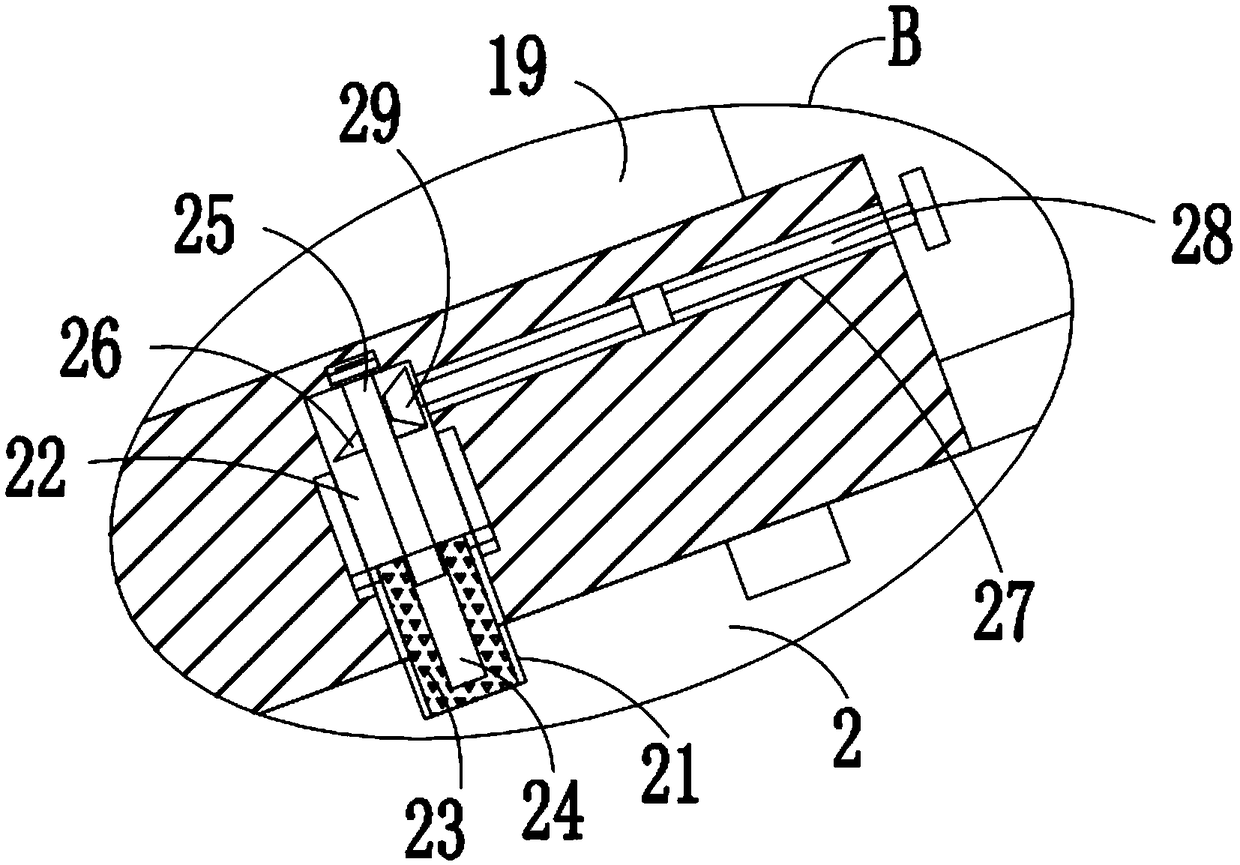

[0024] refer to Figure 1-5In this embodiment, a fixture is proposed to facilitate mold slope processing, including a base 1, the top of the base 1 is hinged with a stage 2, and the stage 2 is inclined, and the bottom of the stage 2 is welded with a connecting seat 3. The connecting rod 4 is installed on the bottom of the connecting seat 3. The connecting rod 4 is inclined. The top of the base 1 is provided with a first chute 5, and the inner wall of the first chute 5 is welded with a first sliding rod 6. A slide slot 5 is slidably installed with a slide seat 7 that is slidably sleeved on the first slide bar 6. The top of the slide seat 7 extends to the outside of the first slide slot 5, and the end of the connecting rod 4 away from the connection seat 3 is rotatably mounted on the On the top of the sliding seat 7, the bottom inner wall of the first chute 5 is provided with a first limiting groove 8, and the bottom of the sliding seat 7 is welded with a first limiting block 9,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com