Vibrating motor upper housing automatic alignment machine

A vibrating motor and aligner technology, which is applied to the field of automatic aligning machines on vibration motors, can solve the problems of slow speed, damage, and low efficiency, and achieve the effects of accurate positioning, easy operation and product quality assurance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

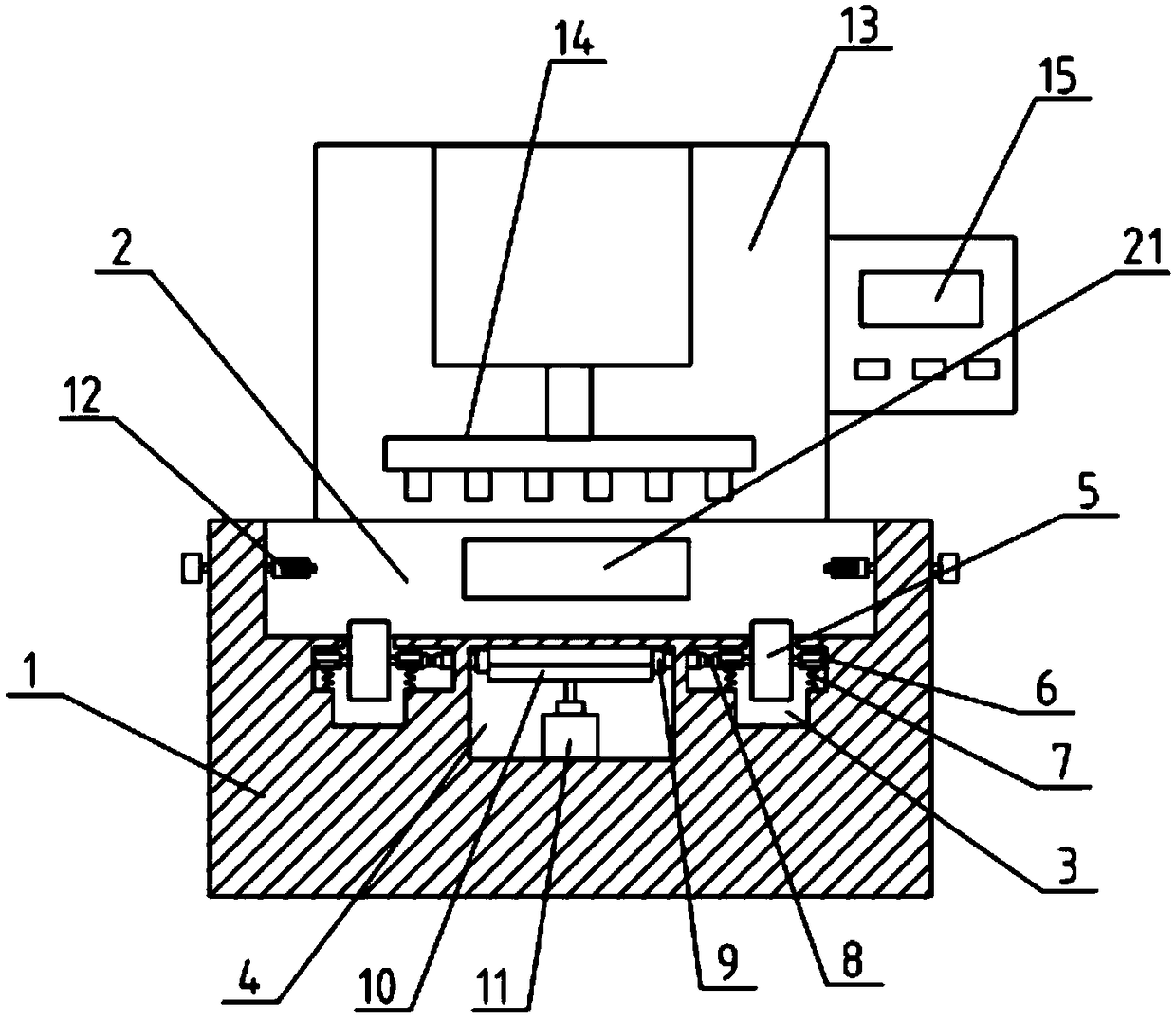

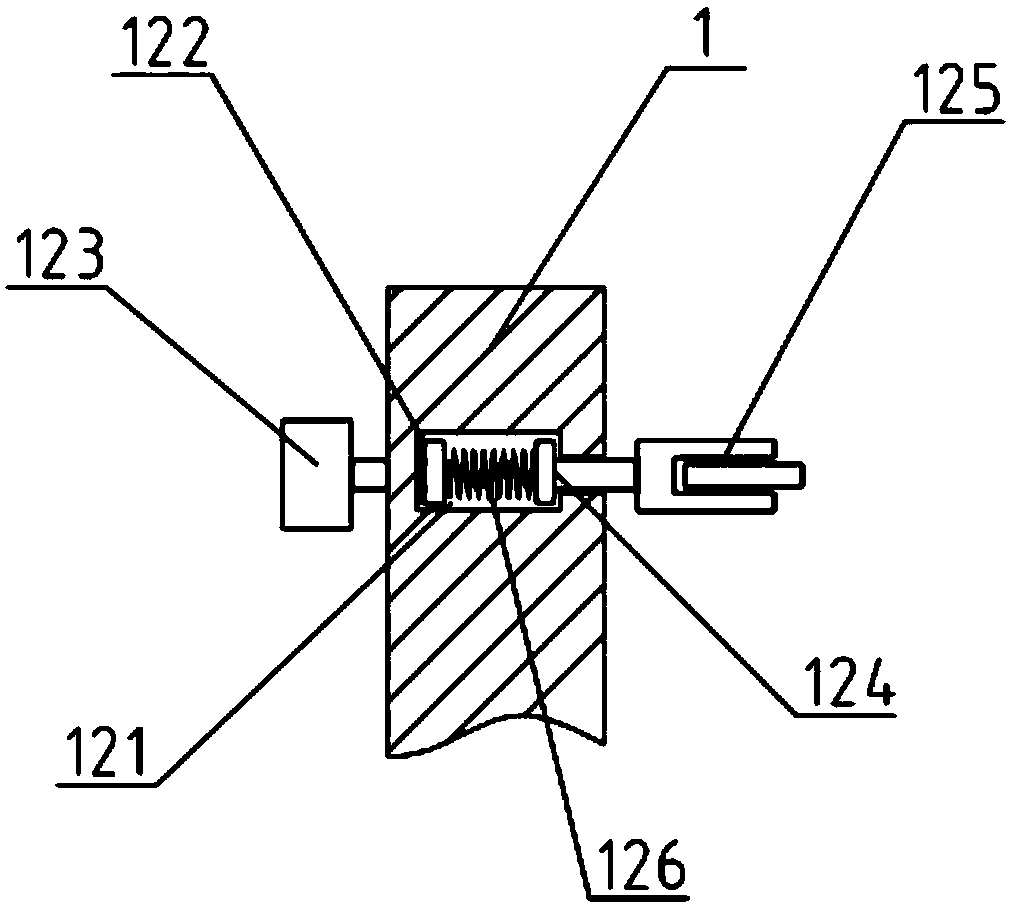

[0019] as attached figure 1 to attach image 3 shown

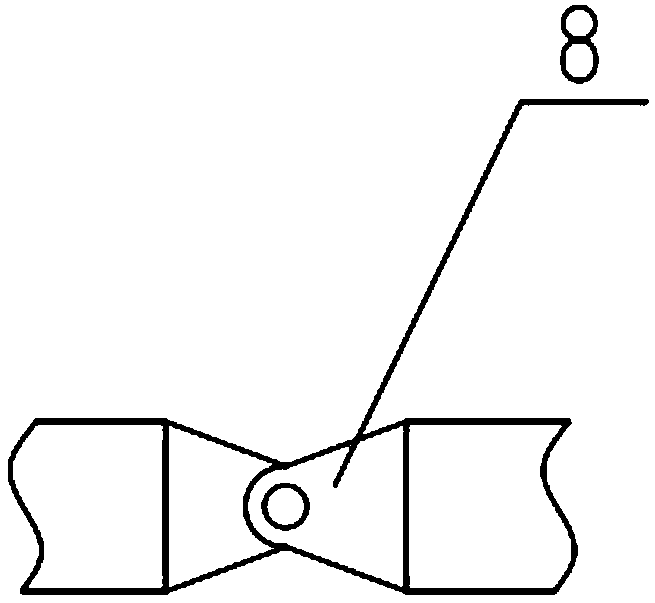

[0020] The present invention provides an automatic alignment machine for the upper casing of a vibrating motor, which includes a base 1, a positioning groove 2, a dial groove 3, a motor groove 4, a dial 5, a sliding sleeve 6, an elastic member 7, a rotating pair 8, and a gear 9. Gear 2 10, drive motor 11, positioning fixture 12, pneumatic punch 13, punch fixture 14 and control module 15, the upper part of the base 1 is provided with a positioning groove 2 for placing product fixtures, and the lower part of the base 1 is sequentially There are a dial groove 3 and a motor groove 4, wherein the dial groove 3 is located on both sides of the base 1, and the motor groove 4 is located in the middle of the base 1; the dial 5 is located in the dial groove 3, and the rotating shafts on both sides pass through the sliding The sleeve 6 is rotatably connected, and the bottom of the sliding sleeve 6 is supported and connected with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com