Camera assembly, vehicle comprising the camera assembly and adjusting method of the camera assembly

A camera component and camera technology, applied in electrical components, image communication, vehicle parts, etc., can solve the problem of inconvenient adjustment of the camera

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

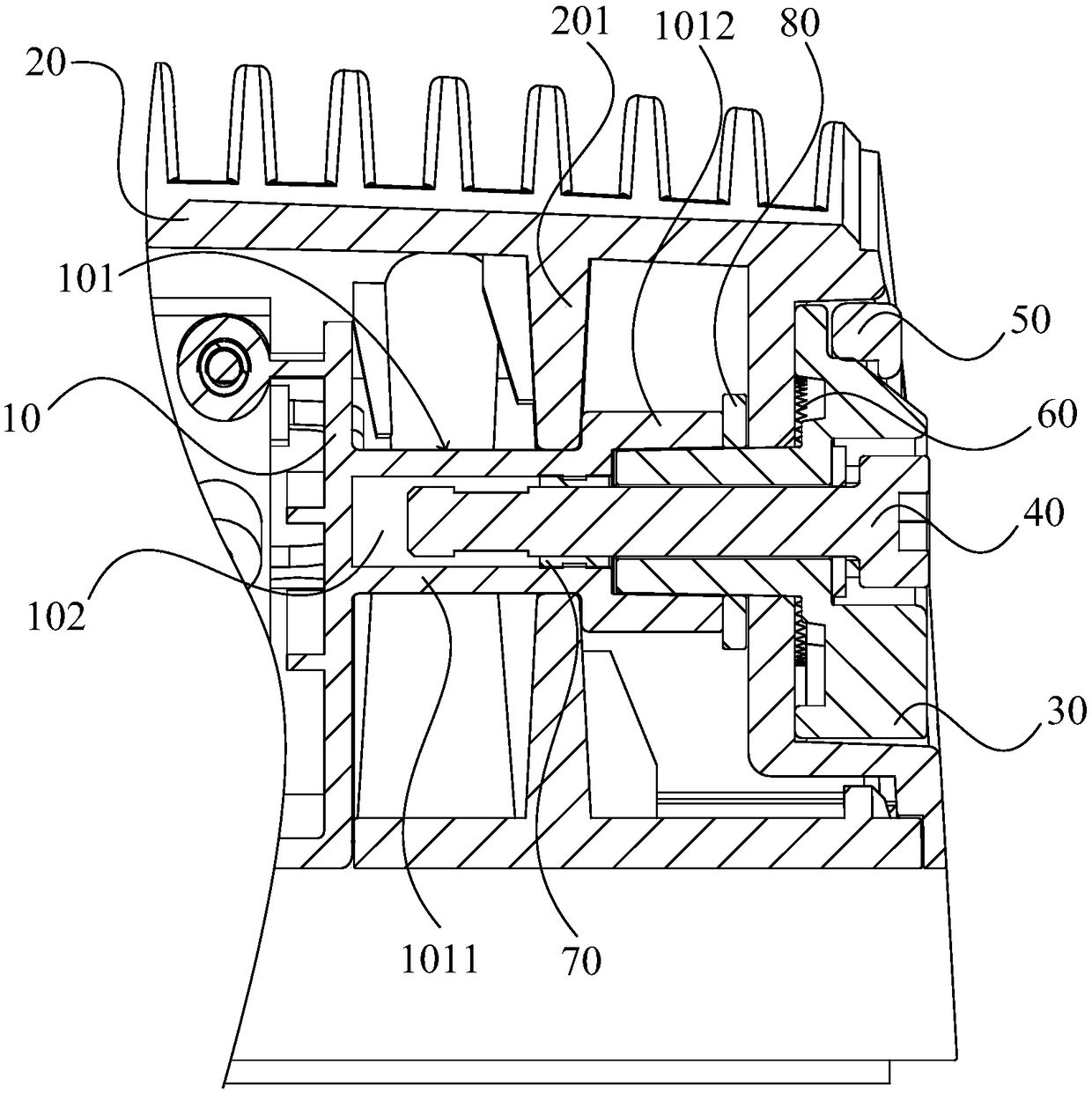

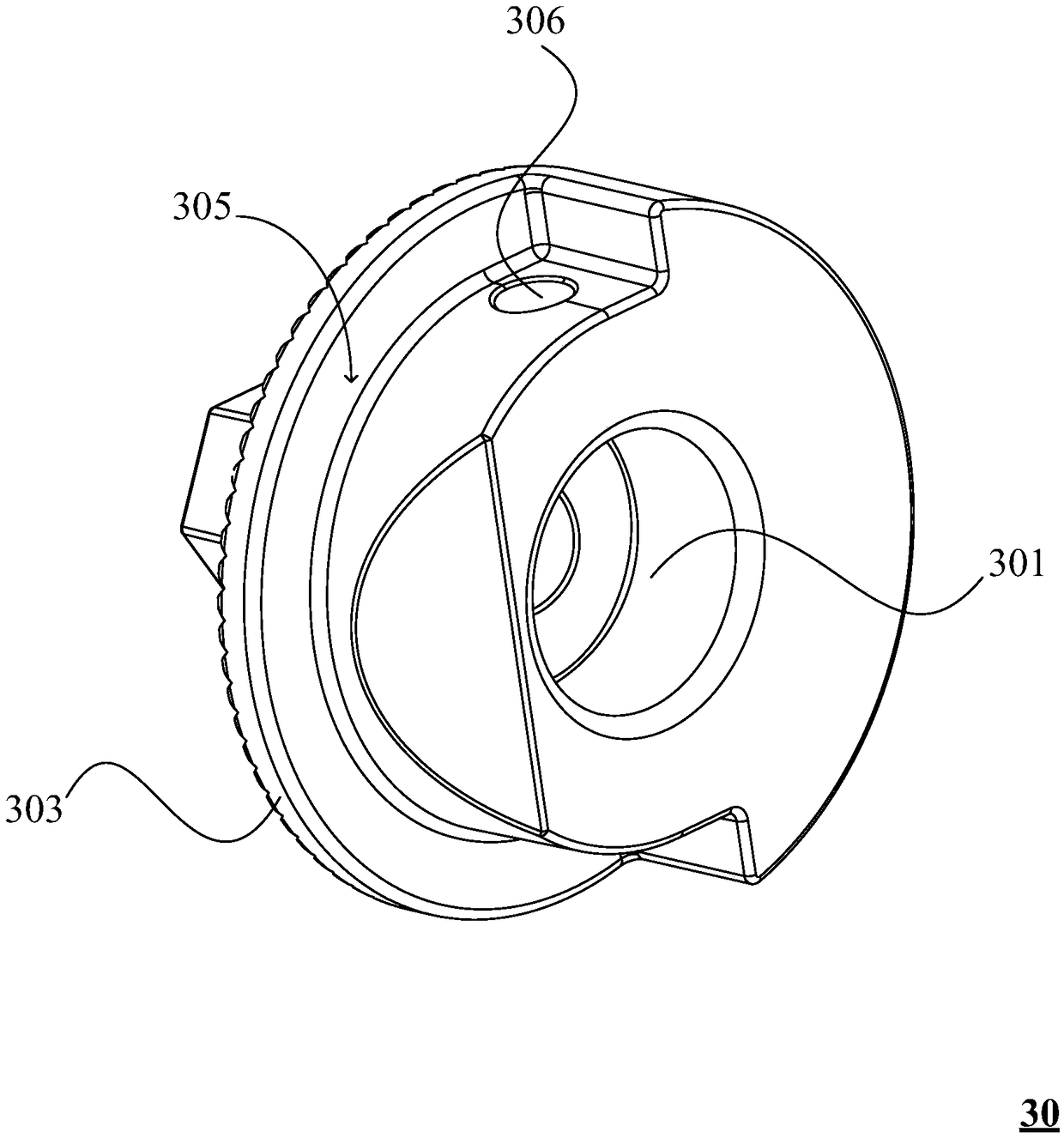

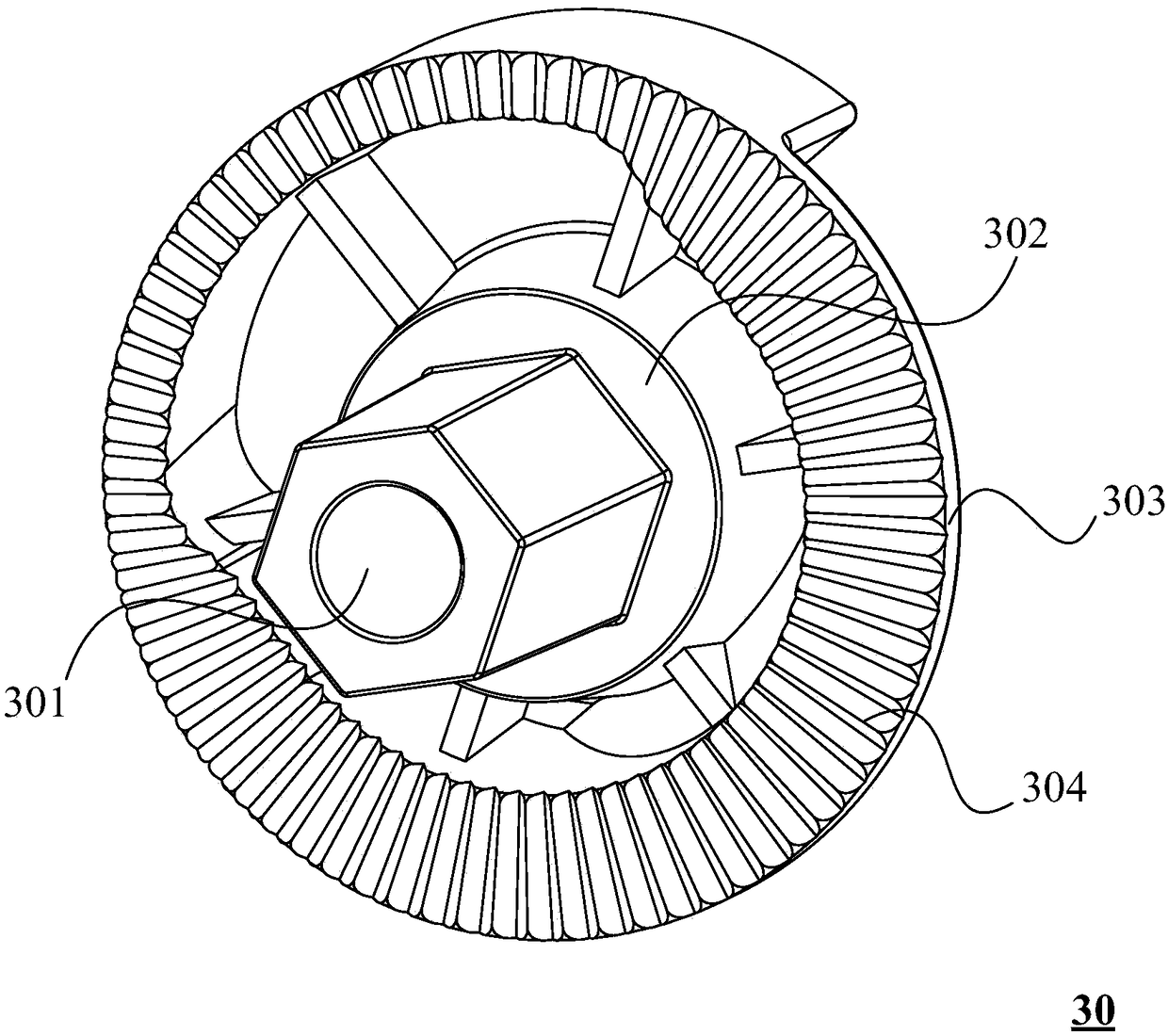

[0069] The present embodiment provides a camera assembly, which can be understood with reference to 1-5. The camera assembly includes a camera mount 10, a camera (not shown in the figure), a housing 20, an adjustment seat 30 and a fastener 40, and the camera mount One end of 10 is clamped on the housing 20, and the other end extends to the outside of the housing 20. The camera is located at the other end of the camera mount 10, and one of the side walls of the camera mount 10 is provided with a wall extending toward the side wall of the housing 20. The extension portion 101 has an accommodating hole 102 along the extension direction, and the extension portion 101 is located inside the housing 20 . The adjustment seat 30 has a head end and a tail end along the extension direction, the head end of the adjustment seat 30 is passed through the housing hole 102 through the side wall of the housing 20, and the tail end of the adjustment seat 30 is attached to the side wall of the hou...

Embodiment 2

[0084] This embodiment discloses a method for adjusting a camera assembly, the camera assembly is the camera assembly in Embodiment 1, refer to Image 6 It should be understood that the adjustment method includes the following steps:

[0085] Step 100, unscrew the fastener;

[0086] Step 200, apply an external force to the force application part along the force application direction, so as to make the adjustment seat and the extension part rotate relative to the casing.

[0087] In this embodiment, when the fastener is unscrewed, the casing, the camera mounting seat and the adjusting seat are still connected together. When an external force is applied to the force application part, the adjusting seat and the extension part rotate relative to the casing. By rotating the adjusting seat The position of the camera mount can be adjusted more conveniently, so that the position of the camera can be adjusted more conveniently.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap