Camera module, assembly method and electronic device

A technology of camera module and assembly method, which is applied in the direction of TV, electrical components, image communication, etc., can solve problems such as weak rigidity, achieve the effects of reducing accumulation, reducing assembly tolerance, and ensuring assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

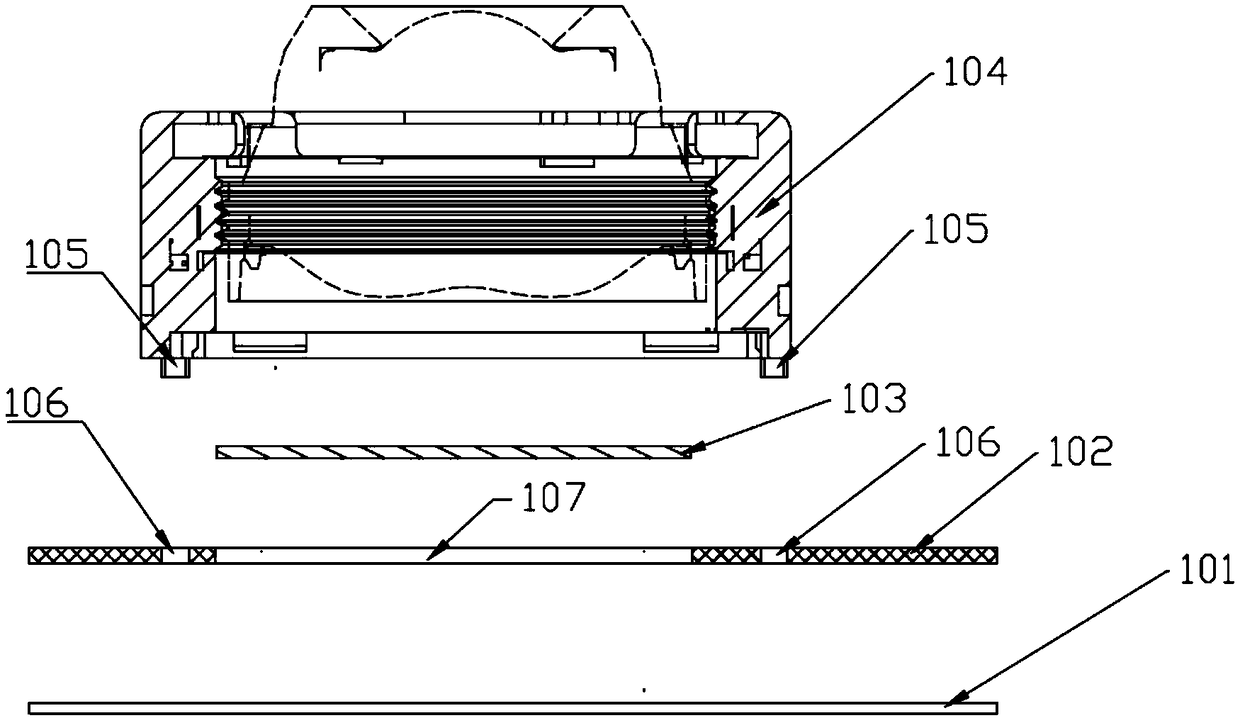

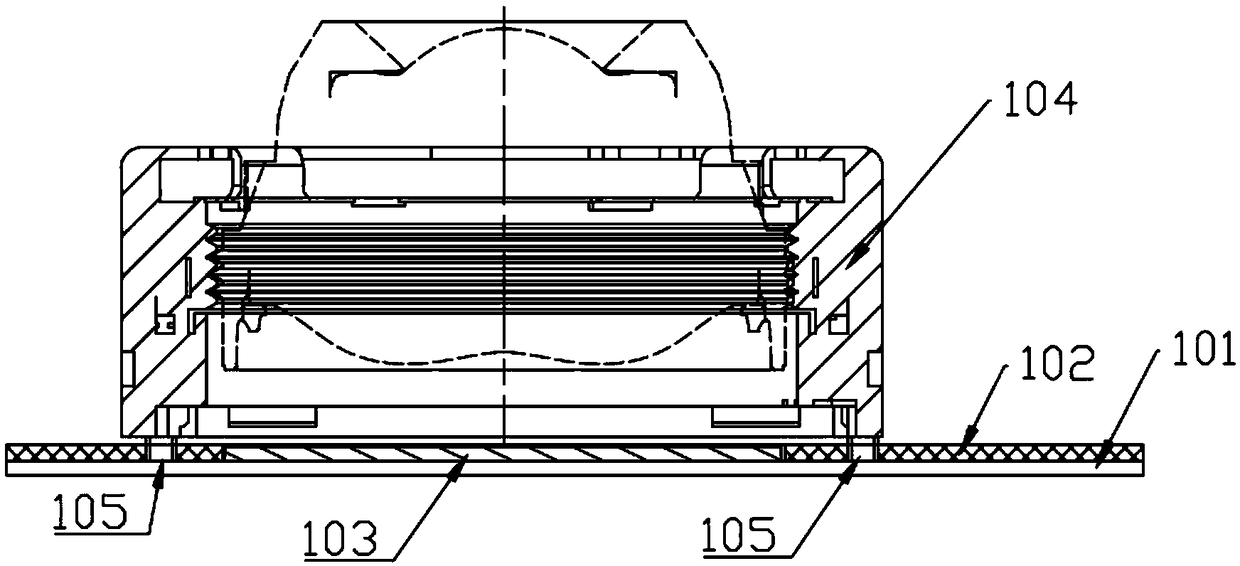

[0032] like figure 2 and image 3 As shown, the camera module provided in this embodiment includes: a reinforcing plate 101 , a circuit board 102 , a photosensitive chip 103 and a lens assembly 104 .

[0033] Wherein, the reinforcing plate 101 may be a metal material, for example, but not limited to, it is implemented as a metal product such as a steel sheet obtained by a process such as stamping. The reinforcing plate 101 has a very high flatness. In addition to supporting and fixing the camera module, it can also provide a very flat reference surface for the photosensitive chip 103 and the lens assembly 104. The photosensitive chip 103 and the lens assembly 104 Mounting based on this reference plane can greatly reduce assembly tolerances.

[0034] The number of circuit boards 102 is not limited. The camera module provided in this embodiment includes one circuit board 102, which is provided with at least one hollow area 107 and at least one positioning hole 106, and is att...

Embodiment 2

[0045] On the basis of Embodiment 1, this embodiment provides a camera module, the camera module includes a reinforcing plate, a circuit board, a photosensitive chip, and a lens assembly, wherein the reinforcing plate, the circuit board, and the photosensitive chip are the same as those in Embodiment 1. are the same, and will not be repeated here.

[0046] The camera module provided in this embodiment is an autofocus module, wherein the lens assembly includes:

[0047] a drive assembly, the drive assembly includes a base, a lens carrier, and a drive member for driving the lens to move, and a surface of the base is provided with at least one positioning post extending outward;

[0048] a lens, the lens is mounted on the lens carrier of the drive assembly;

[0049] a filter element, mounted on the base of the drive assembly;

[0050] The lens and the filter element are sequentially located on the photosensitive path of the photosensitive chip.

[0051] It is worth mentioning ...

Embodiment 3

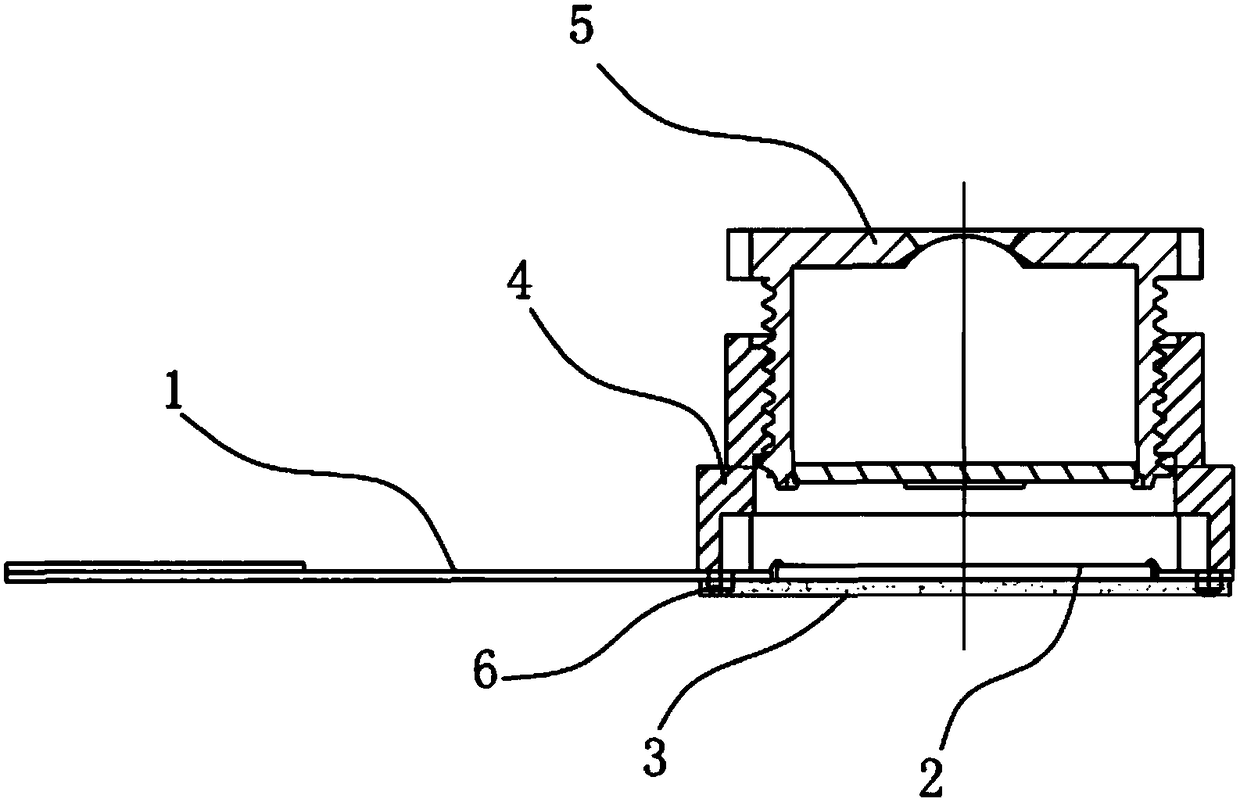

[0061] On the basis of Embodiment 1, this embodiment provides a camera module, the camera module includes a reinforcing plate, a circuit board, a photosensitive chip, and a lens assembly, wherein the reinforcing plate, the circuit board, and the photosensitive chip are the same as those in Embodiment 1. are the same, and will not be repeated here.

[0062] The camera module provided in this embodiment is a fixed-focus module, wherein the lens assembly includes:

[0063] a base, a surface of the base is provided with at least one positioning post extending outward;

[0064] a filter element, the filter element is arranged on the other end face of the base opposite to the positioning column;

[0065] a lens, the lens is arranged on the base;

[0066] The lens and the filter element are sequentially located on the photosensitive path of the photosensitive chip.

[0067] Specifically, the filter element is a filter, and the lens and the filter element are sequentially located o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com