A flexible automatic splitting machine based on bead

A split machine and flexible technology, applied in the field of bead manufacturing, can solve the problems of increased manufacturing cost, large labor force, and uneven quality of manual work, so as to ensure product quality, reduce time waste, and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

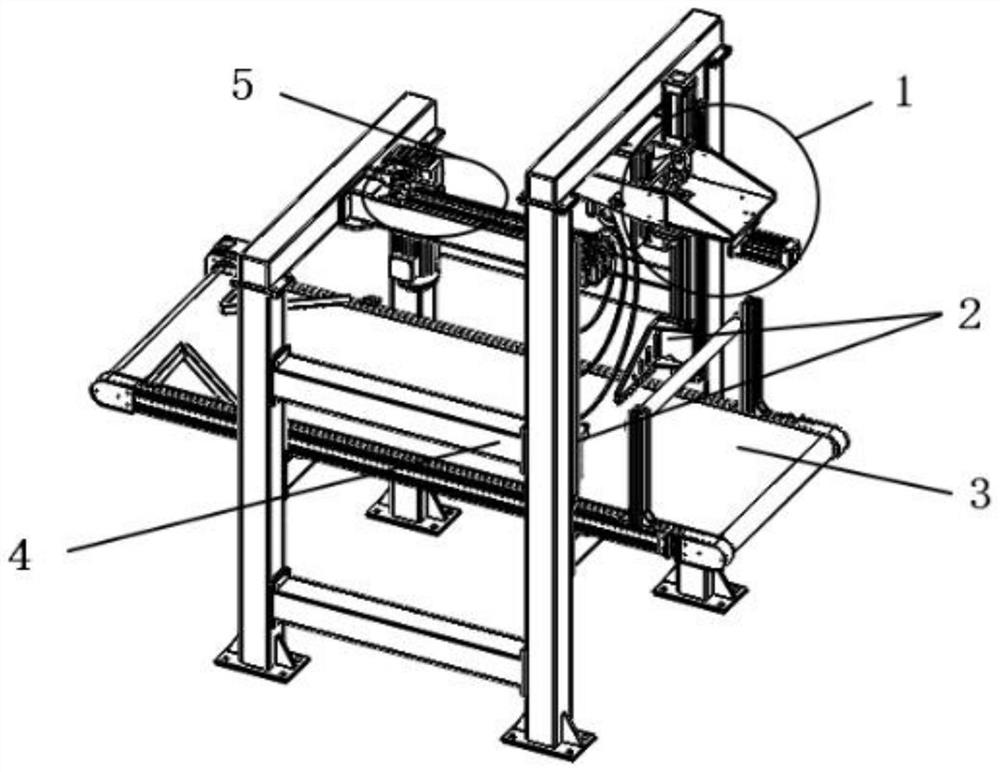

[0024] Such as figure 1 As shown, a bead-based flexible automatic splitting machine includes a square tube frame 4, a controller, a splitting component 1 communicating with the controller, a splitting component 2, a conveyor belt 3 and a suspension arm 5. The split part 1 is installed on the square tube frame 4 through the lifting part mounting seat 140. The split part 1 mainly uses the movement of the cylinder to drive the up and down movement of the lifting device 110 and the back and forth movement of the pulling device 120; the lifting device 110 is mainly used to To drive the pulling device 120 and the pressing device 130 to move up and down.

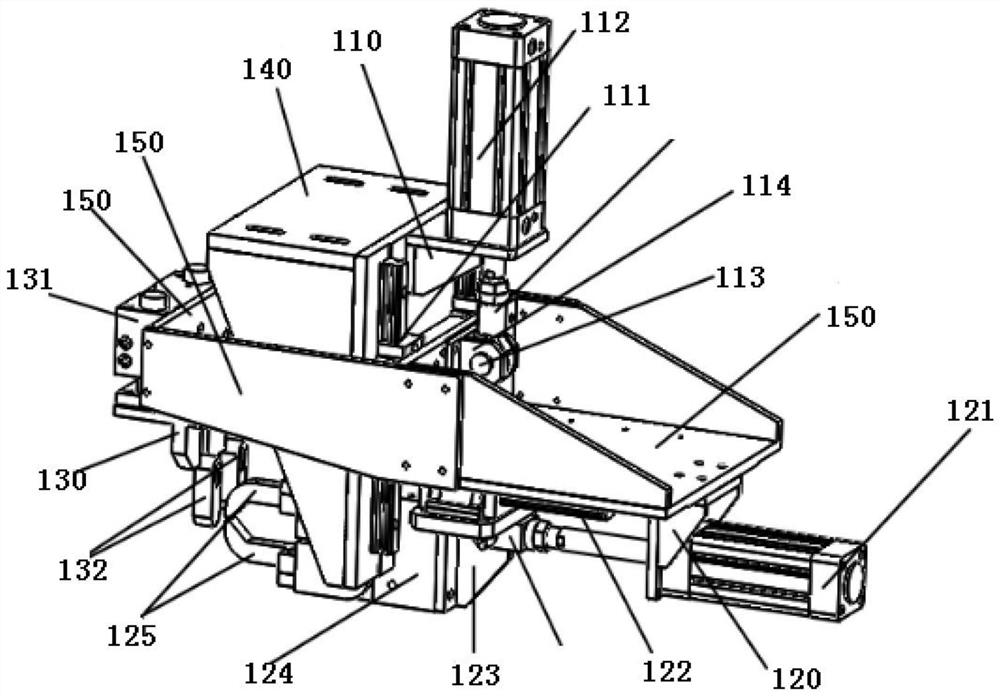

[0025] Such as figure 2 As shown, the disassembled part 1 includes a lifting device 110, a pulling device 120, a pressing device 130, a mounting base 140 and a mounting side plate 150, the upper side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com