Refrigerator

A refrigerator and box technology, applied in the field of home appliances, can solve problems such as inability to use, occupy, and large storage space, and achieve the effect of avoiding condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

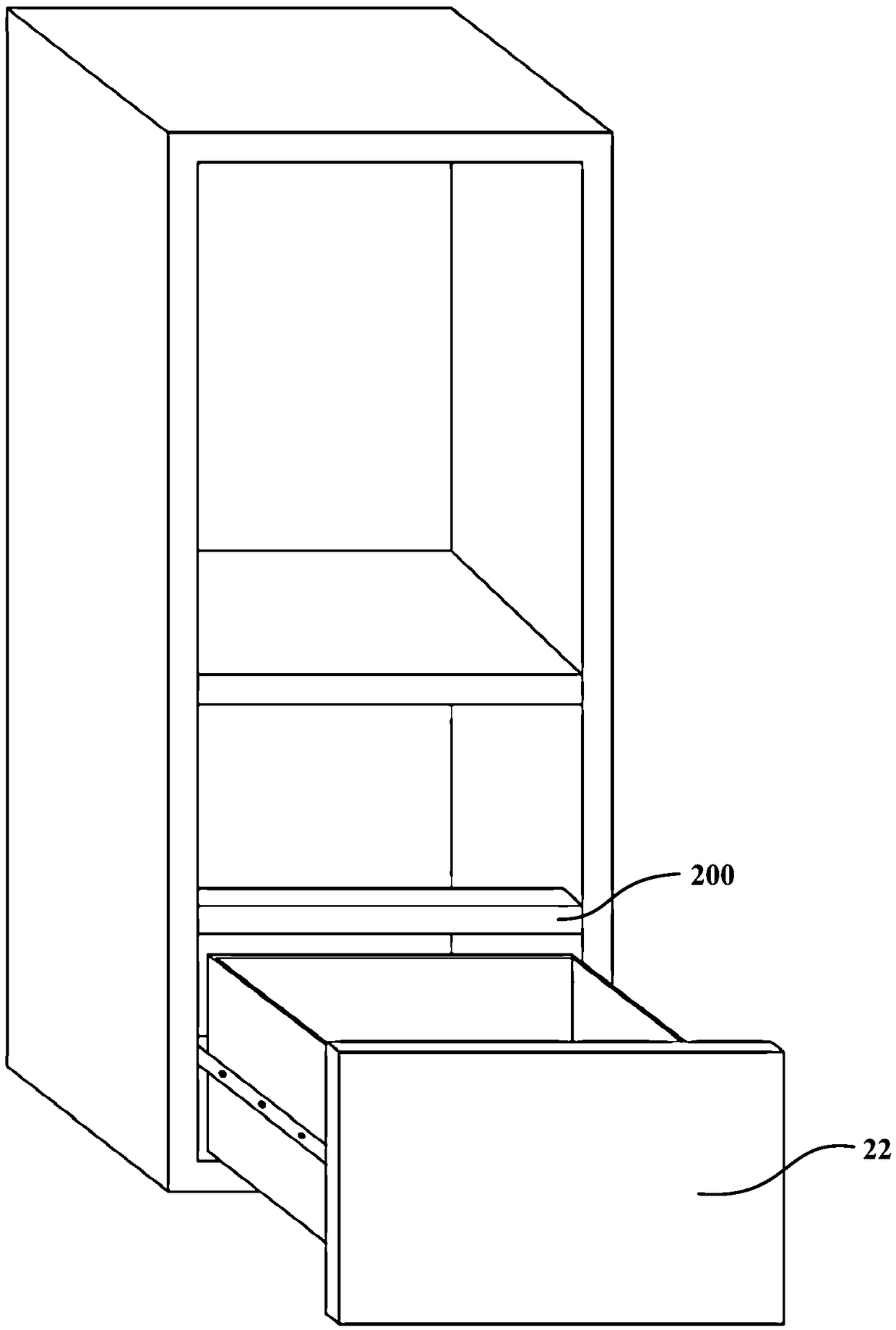

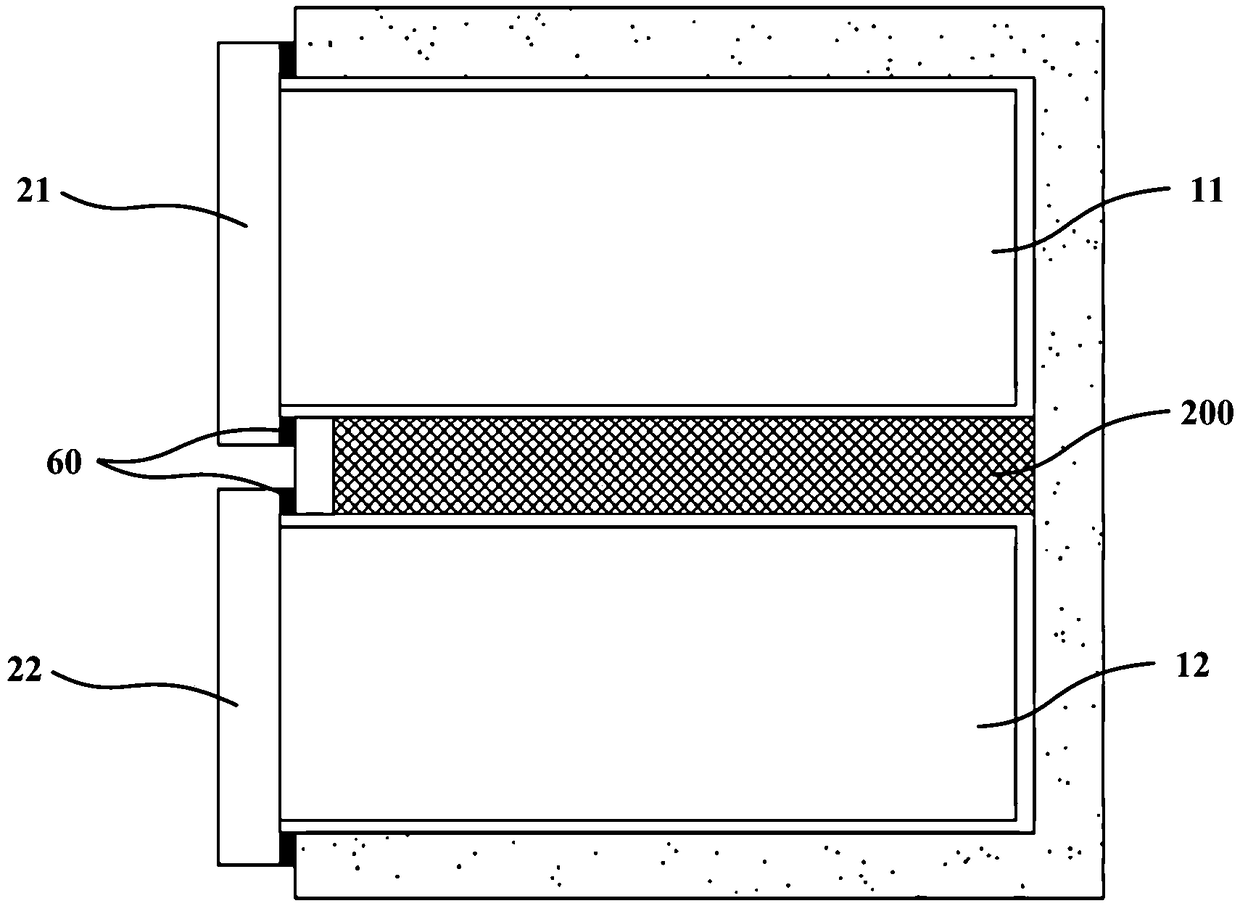

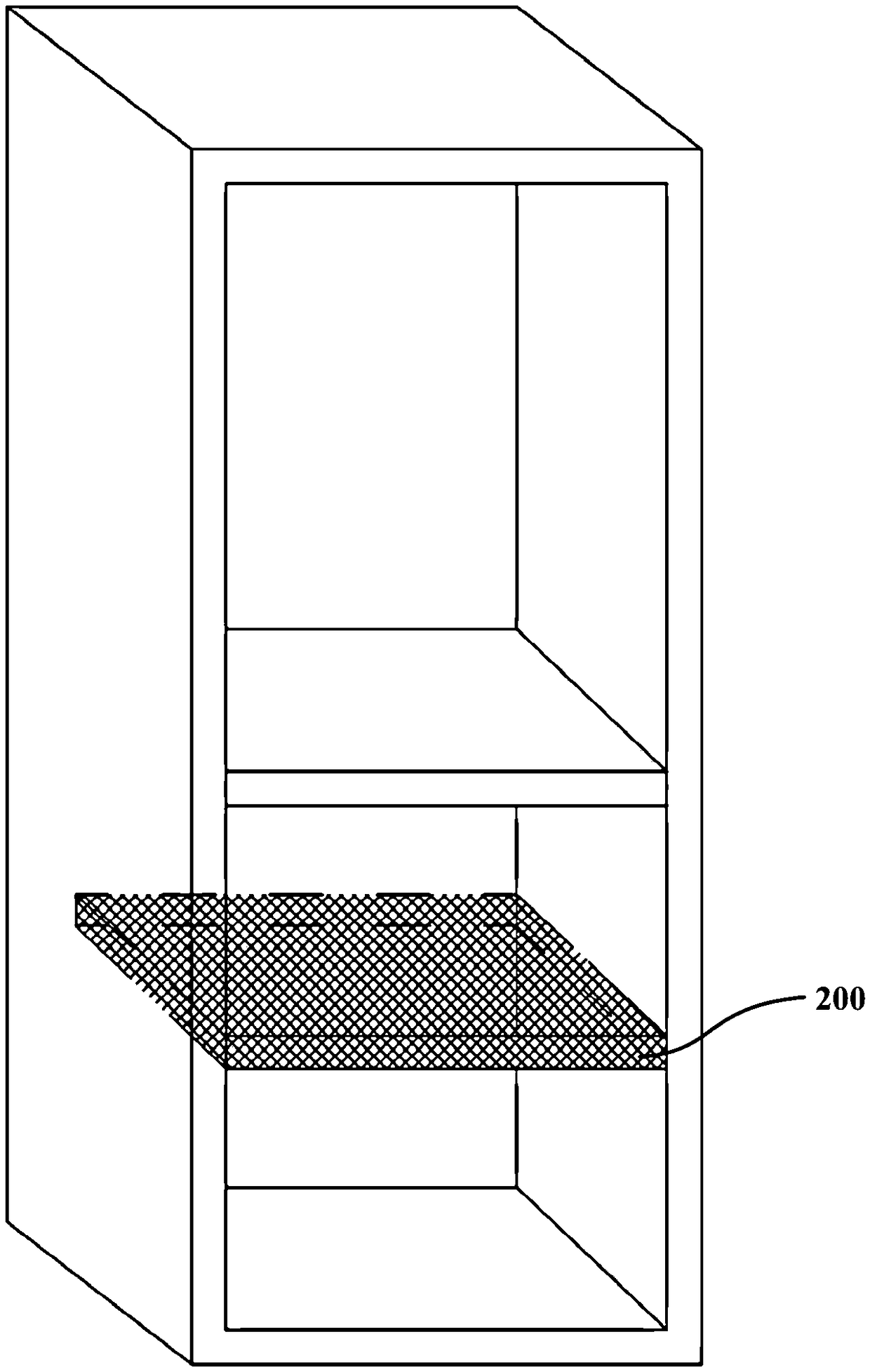

[0031] figure 1 It is a schematic diagram of the sealed drawer door of the refrigerator in the prior art when it is opened, figure 2 It is a schematic diagram when the sealed drawer door of the refrigerator in the prior art is closed, image 3 It is a structural schematic diagram of a beam 200 of a refrigerator in the prior art. Such as Figure 1 to Figure 3 As shown, when the refrigerator in the prior art is provided with the first drawer 11 and the second drawer 12 adjacent to each other up and down, the first door body 21 of the first drawer 11 and the second door body of the second drawer 12 will A fixed crossbeam 200 is arranged between 22, so that some of the door seals 60 on the first drawer 11 and the second drawer 12 can be pressed on the crossbeam 200 here, so as to avoid the leakage of cold energy at the door seal 60. In order to ensure the thermal insulation at the door seal 60, the pressing portion of the door seal 60 and the beam 200 is at least 8mm. And in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com