Extruder

A technology of extruder and hopper, which is applied in the field of plastic processing machinery and equipment, can solve the problems of material accumulation on the screen, and the bouncing effect is not obvious, so as to avoid waste and structure blockage and ensure the quality of extrusion molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

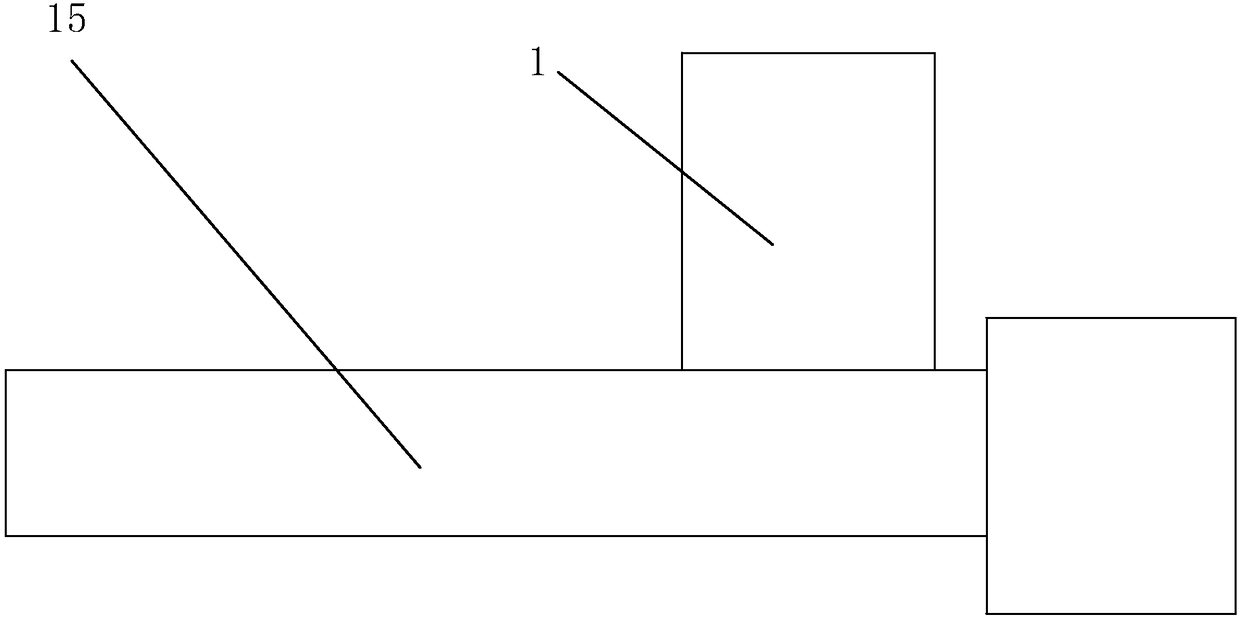

[0040] Embodiment 1: a kind of extruder, such as figure 1 As shown, it mainly includes a hopper 1 for materials to enter. The lower end of the hopper 1 is connected to the barrel 15. A transmission screw is arranged in the barrel 15. The material is thrown into the hopper 1 through the upper end of the hopper 1 and enters the barrel 15. It falls on the transmission screw, and is plasticized into a uniform melt during the transmission process of the transmission screw, and under the pressure established in this process, it is continuously extruded by the screw head to complete the extrusion of the material. .

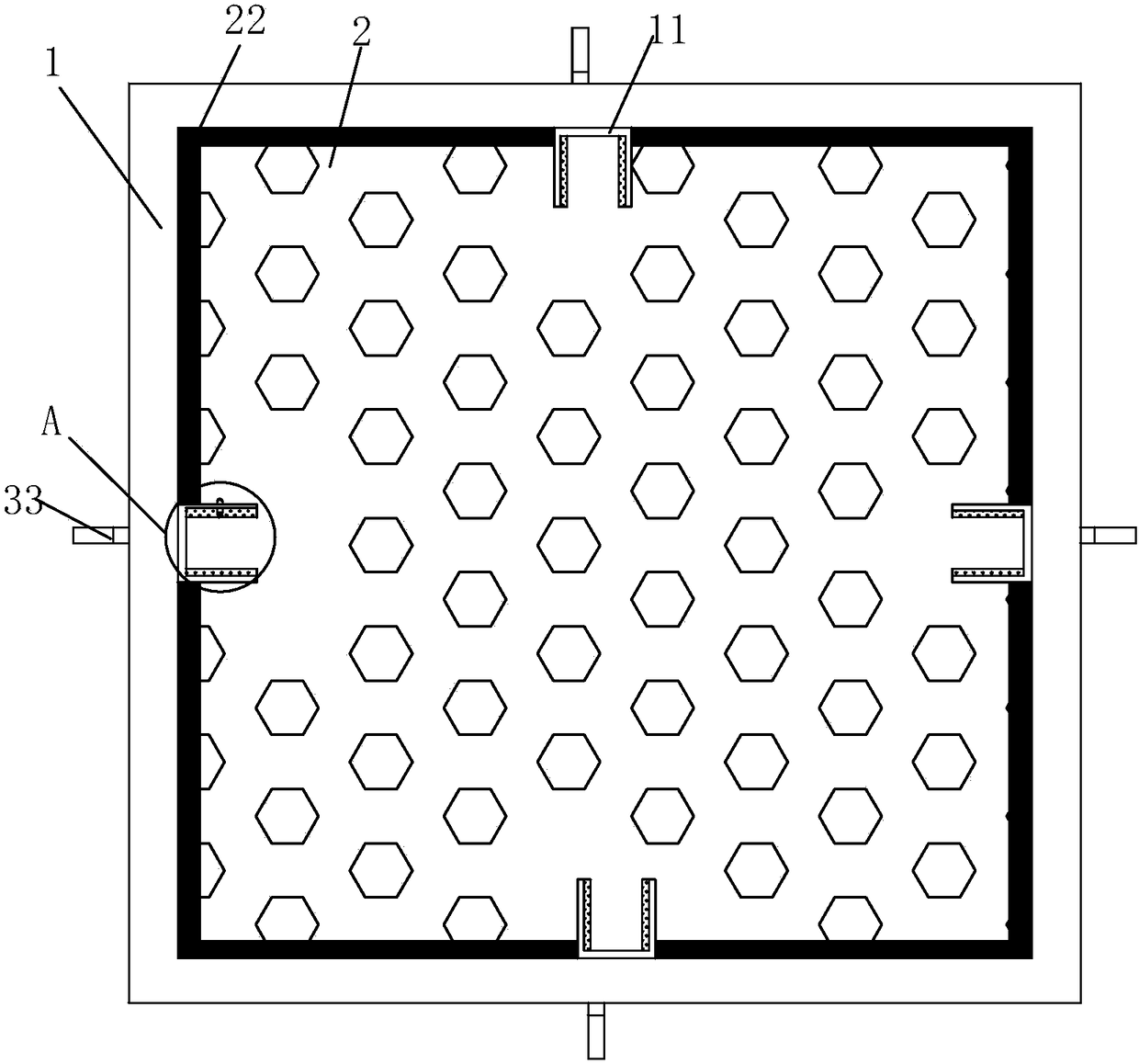

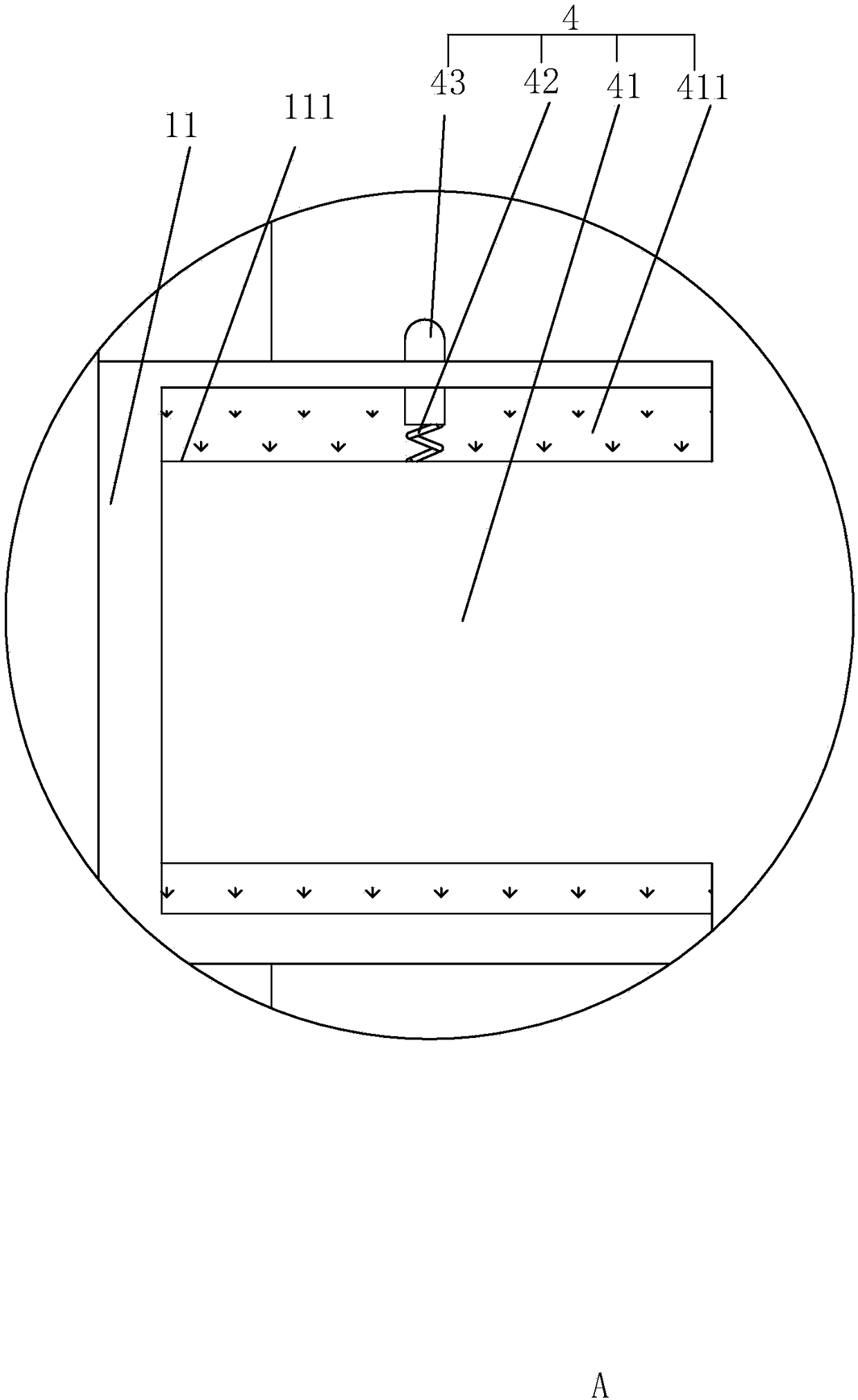

[0041] Such as figure 2 and 4 As shown, the cross section of the inner hole of the hopper 1 is in a square shape, and track grooves 16 are arranged on the four surfaces of the inner wall of the hopper 1, and supports 11 are slidingly connected in the track grooves 16, between the supports 11 Symmetrical in pairs; each support 11 is provided with a storage slot 111, t...

specific Embodiment approach

[0045] Specific implementation: before the extruder works, the sieve plate 2 needs to be installed in the extruder, that is, the sieve plate 2 is mounted on the support 11, and each extension column 41 of the sieve plate 2 is respectively embedded When the extension column 41 with the limiting column 43 is completely embedded in the storage slot 111, the limiting column 43 will firstly interfere with the inner wall of the storage slot 111, and under the action of this resistance, the compression The spring 42 is fully compressed. When the extension column 41 is fully embedded in the storage slot 111, the limiting column 43 slides along the inner side wall of the storage slot 111 to the through hole 44. At this time, the limiting column 43 is embedded in the through hole 44. The inside communicates with the outside, and at the same time, the compression spring 42 resumes its deformation. At this time, the locking of the extension column 41 in the storage slot 111 can be realized...

Embodiment 2

[0052] Embodiment 2: An extruder, the difference from Embodiment 1 is that during the process of feeding materials into the hopper 1 through the upper opening of the hopper 1, some materials will fall on the support 11 to form a The accumulation on the seat 11 will cause material waste at this time. In order to avoid this phenomenon, the upper end of the support 11 on the inner wall of the hopper 1 is provided with a deflector 14 to prevent the material from falling into the support 11. Such as Figure 6 and 7 As shown, the deflector 14 is adjusted in the hopper 1 through the adjustment device 5, so as to realize the diversion of the material and prevent the material from falling and accumulating on the support 11. At the same time, the deflector 14 can also be controlled to let out A space for the sieve plate 2 to be taken out from the hopper 1 smoothly.

[0053] Such as Figure 6 and 7 As shown, the adjusting device 5 includes working grooves 51 arranged on the inner wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com