Upper driving mechanism applicable for high-speed stacker

A technology of driving mechanism and stacker, which is applied to the stacking of objects, unstacking of objects, transportation and packaging, etc., which can solve the problems of long time required and difficulty in ensuring synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

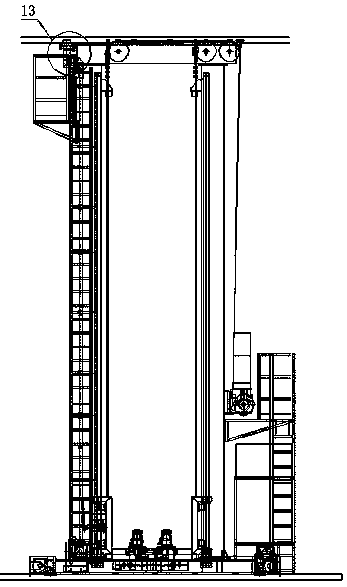

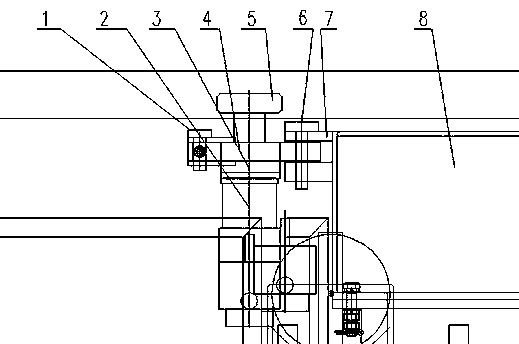

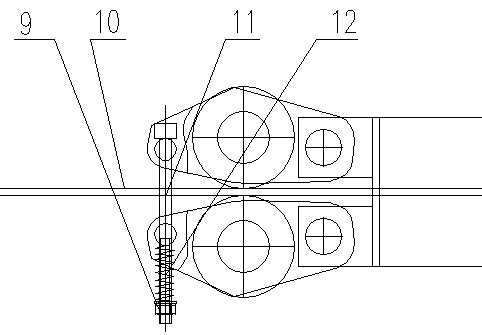

[0023] like Figure 1-3 As shown, the present invention discloses an upper driving mechanism applied to a high-speed stacker. Its structure includes a pin with a hole, a driving mechanism, a crank, a driving wheel, a pin, a mounting plate, an upper box, a lock nut, Guide rails, connecting rods and tensioning springs. Drive wheels and servo motors are mounted on the crank structure. The driving mechanism is a servo motor and a reducer, the servo motor and the reducer are installed in series, and the reducer is installed on the mounting plate. The present invention adopts the form driven by two motors, each of which is equipped with a drive wheel, and the servo motor can drive the drive wheel to rotate through the reducer. The driving wheels are made of polyurethane material to increase friction, and the two driving wheels ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com