Scratch-resistant conductive coating

A conductive coating, anti-scratch technology, applied in conductive coatings, coatings, anti-corrosion coatings, etc., can solve the problem of poor anti-aging and corrosion resistance of conductive coatings, poor scratch resistance of conductive coatings, and affect the appearance of products And other problems, to improve the anti-scratch performance, avoid aging effect, improve the effect of anti-aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

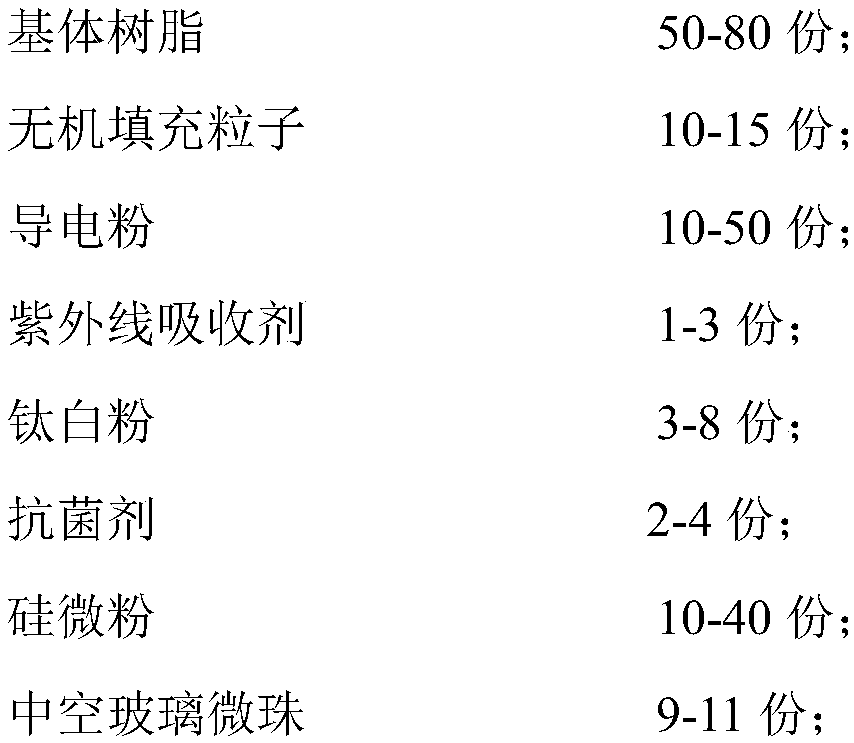

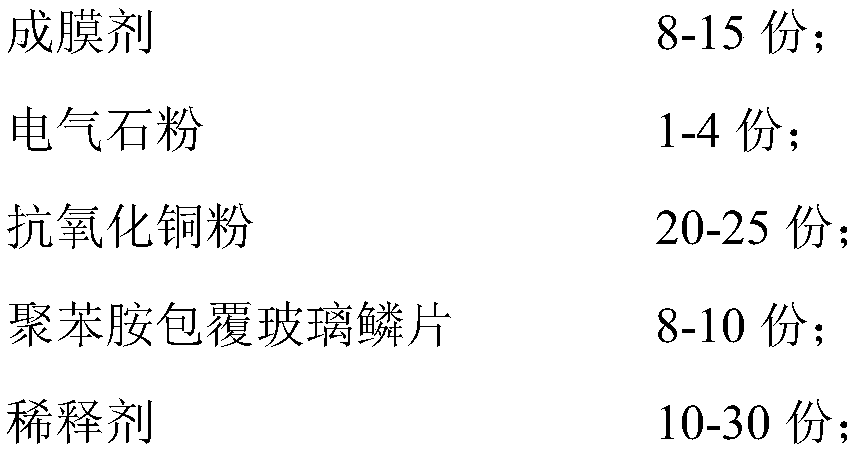

[0027] Example 1 A scratch-resistant conductive coating consisting of the following components by weight:

[0028]

[0029]

[0030] The inorganic filler particles form protrusions on the conductive coating, the height of the protrusions is 3 μm, and the coverage of the protrusions on the surface of the conductive coating is 30%.

[0031] The antibacterial agent is at least one of nano silver antibacterial agent, titanium dioxide antibacterial agent, nano zinc oxide antibacterial agent, and chitosan.

[0032] The inorganic filler particles are Al 2 O 3 , ZnO, MgO, CuO, MnO 2 , Fe 2 O 3 At least one or a combination of both.

[0033] The titanium dioxide is rutile titanium dioxide, and the average particle size of the titanium dioxide is 0.1 μm.

[0034] The antioxidant copper powder is composed of the following raw materials in parts by weight: 20 parts of epoxy resin, 65 parts of copper powder; 3 parts of curing agent, 1 part of oleic acid, 1.5 parts of benzotriazole, and 0.5 parts of ...

Example Embodiment

[0037] Example 2 A scratch-resistant conductive coating, characterized in that it consists of the following components by weight:

[0038]

[0039]

[0040] The inorganic filler particles form protrusions on the conductive coating, the height of the protrusions is 15 μm, and the coverage of the protrusions on the surface of the conductive coating is 60%.

[0041] The antibacterial agent is at least one of nano silver antibacterial agent, titanium dioxide antibacterial agent, nano zinc oxide antibacterial agent, and chitosan.

[0042] The inorganic filler particles are Al 2 O 3 , ZnO, MgO, CuO, MnO 2 , Fe 2 O 3 At least one or a combination of both.

[0043] The titanium dioxide is rutile titanium dioxide, and the average particle size of the titanium dioxide is 1 μm.

[0044] The antioxidant copper powder is composed of the following raw materials in parts by weight: 22 parts of epoxy resin, 70 parts of copper powder; 4.5 parts of curing agent, 1.5 parts of oleic acid, 2 parts of benzot...

Example Embodiment

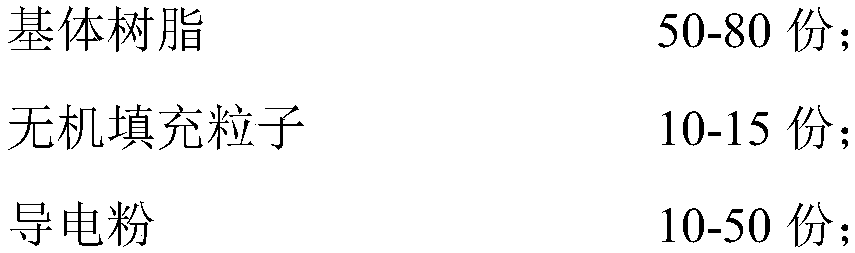

[0047] Example 3 A scratch-resistant conductive coating, which is characterized in that it consists of the following components by weight:

[0048]

[0049]

[0050] The inorganic filler particles form protrusions on the conductive coating, the height of the protrusions is 8 μm, and the coverage of the protrusions on the surface of the conductive coating is 45%.

[0051] The antibacterial agent is at least one of nano silver antibacterial agent, titanium dioxide antibacterial agent, nano zinc oxide antibacterial agent, and chitosan.

[0052] The inorganic filler particles are Al 2 O 3 , ZnO, MgO, CuO, MnO 2 , Fe 2 O 3 At least one or a combination of both.

[0053] The titanium dioxide is rutile type titanium dioxide, and the average particle size of the titanium dioxide is 0.5 μm.

[0054] The antioxidant copper powder is composed of the following raw materials in parts by weight: 21 parts of epoxy resin, 68 parts of copper powder; 3.7 parts of curing agent, 1.2 parts of oleic acid, 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com