Yarn spraying device for processing graphite tetrafluoride synthetic fiber

A synthetic fiber and graphite technology, used in filament generation, textiles and papermaking, etc., can solve the problems of inability to apply different specifications of fiber spinning, poor fiber spinning effect, accurate fiber movement, etc., to increase the scope of application, The effect of wide application range and high guiding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

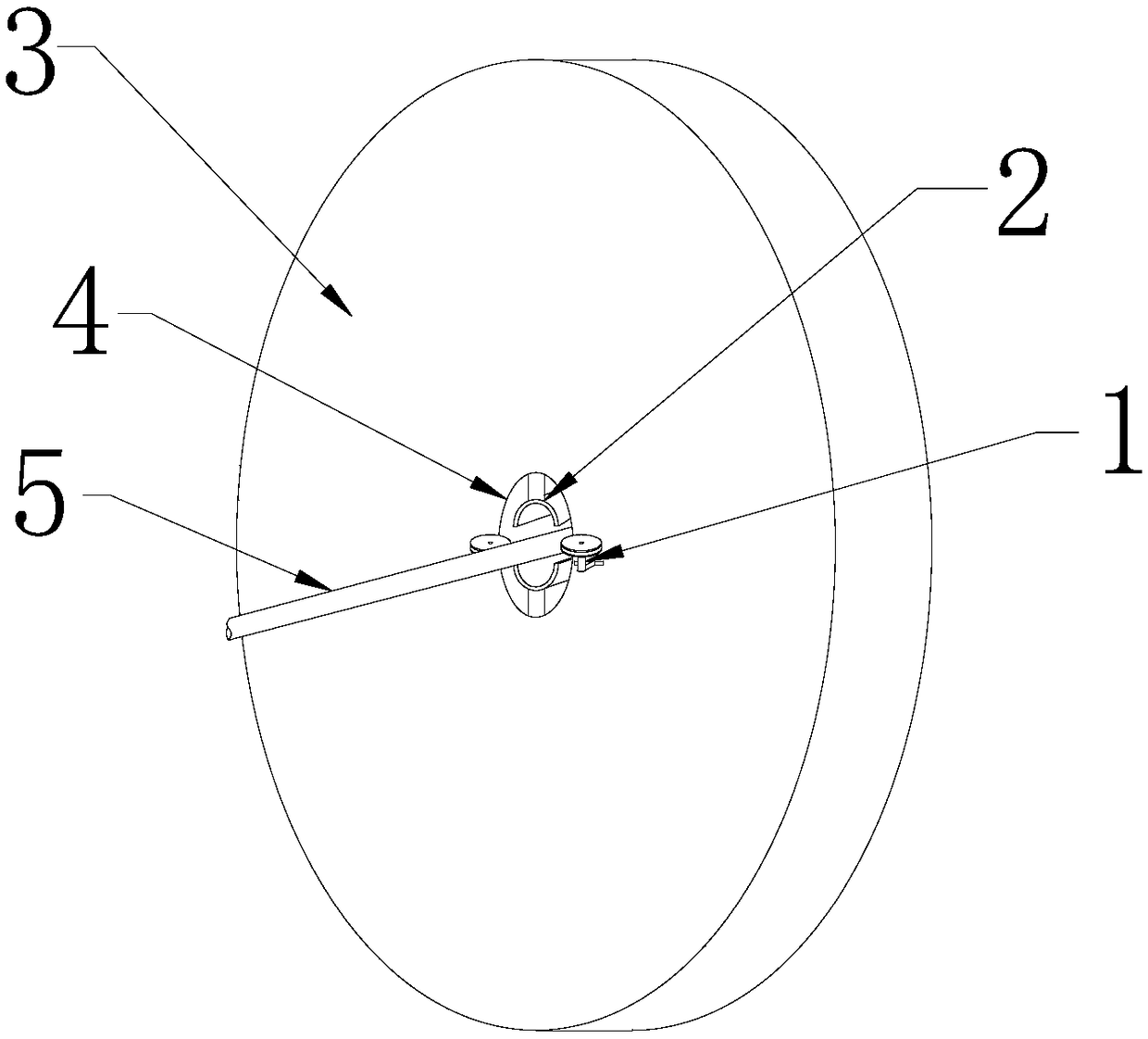

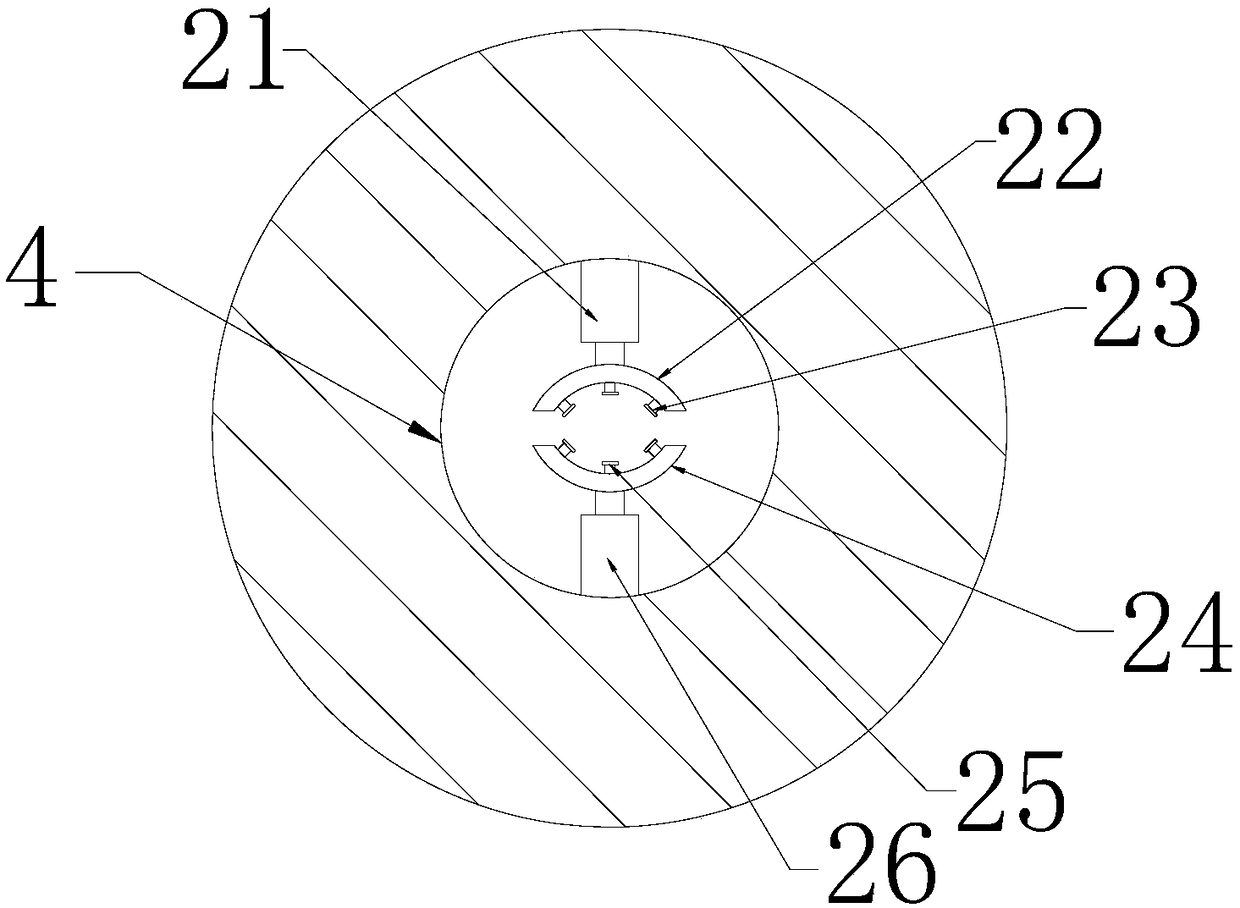

[0019] See Figure 1-Figure 3 , The present invention provides a technical solution: a yarn spraying device for processing graphite PTFE synthetic fiber, comprising a device main body, a guide mechanism 1 and a yarn spraying mechanism 2. The device main body includes a carrier plate 3, a central nozzle hole 4 and graphite PTFE In the synthetic fiber body 5, the central spray hole 4 is opened in the center of the carrier plate 3, and the graphite tetrafluoro synthetic fiber body 5 is arranged in the central spray hole 4.

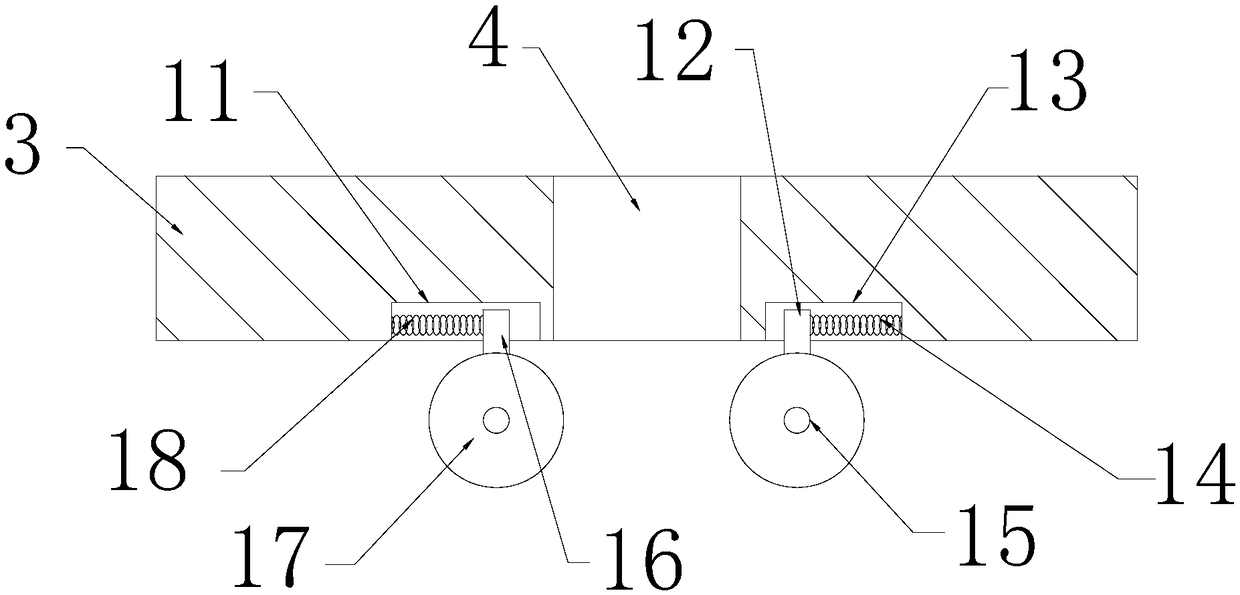

[0020] The guide mechanism 1 is arranged at the middle of the front end of the tray 3. The guide mechanism 1 includes a guide slot 11, a bracket 2 12, a guide slot 2 13, a return spring 14, a right guide wheel 15, a support 16, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com