A washing machine and its control method

A control method and washing machine technology, which are applied in the control device of washing machine, other washing machines, washing devices, etc., can solve the problem of inability to accurately measure the water intake of a non-porous inner cylinder, and achieve a clear design concept, improve washing capacity, and increase volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

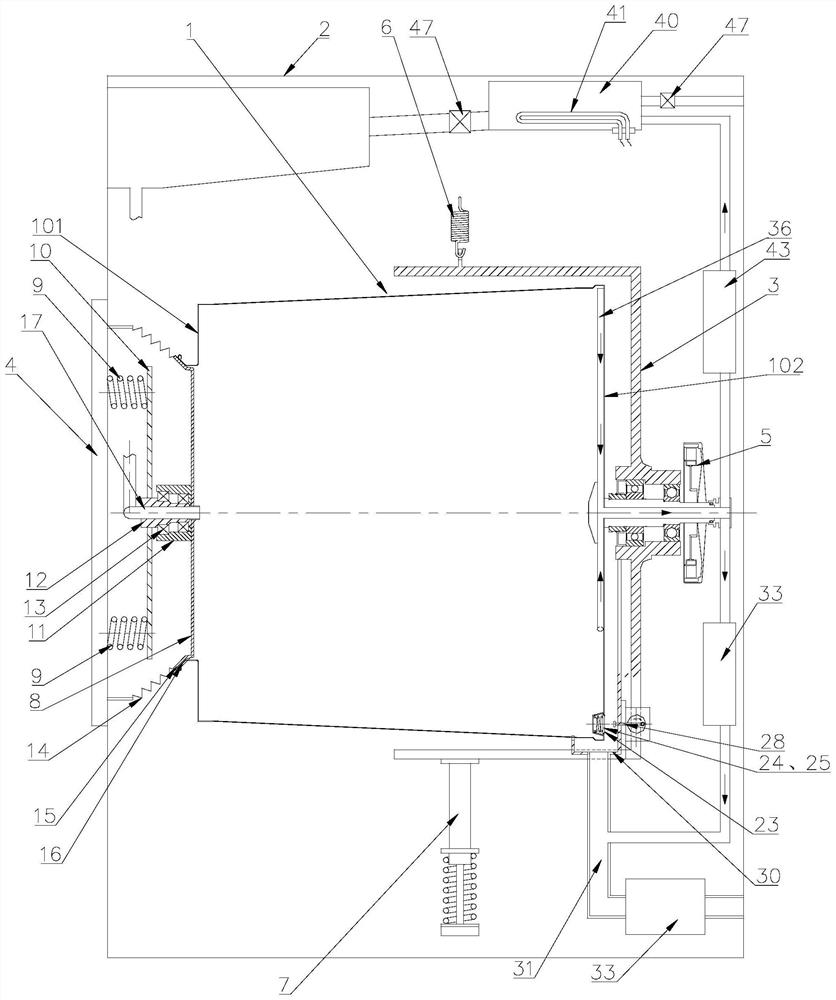

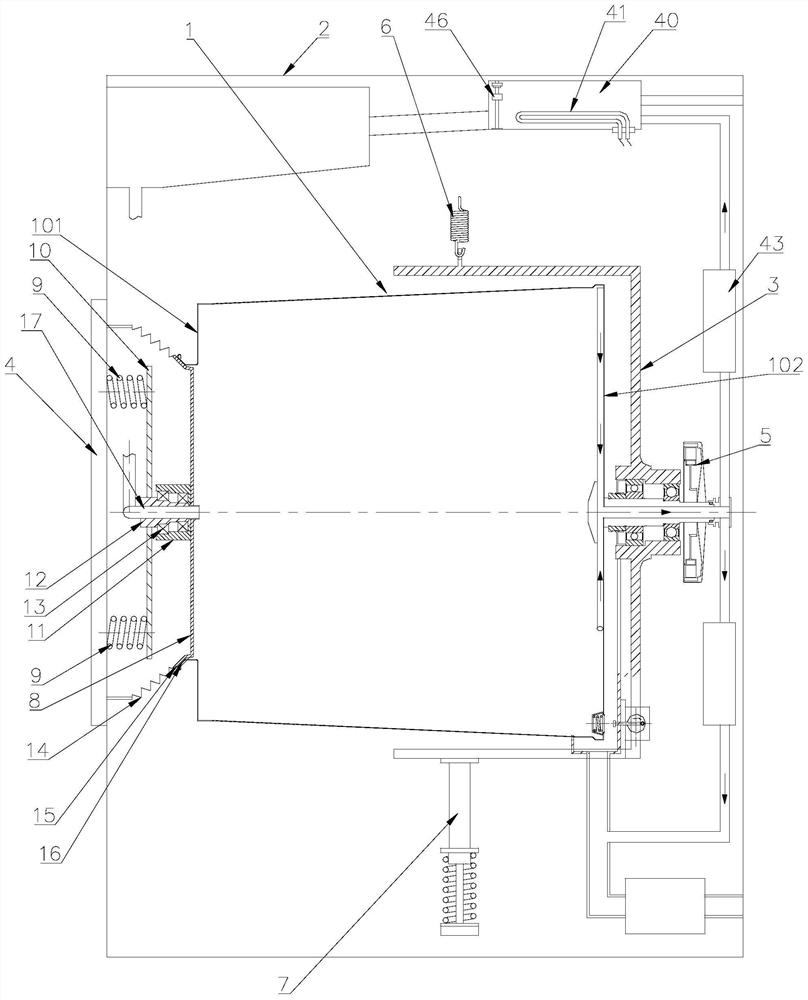

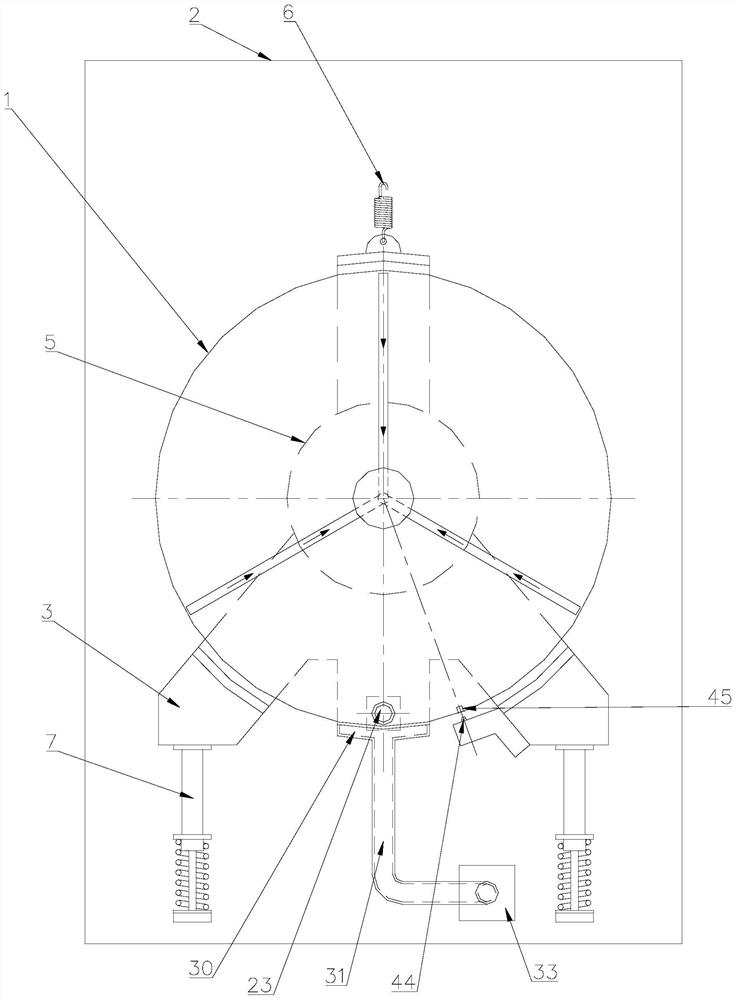

[0050] like figure 1 and figure 2 As shown in the figure, a washing machine is introduced in this embodiment. A sealed inner cylinder 1 is installed in the shell 2 of the washing machine. The inner cylinder 1 is communicated with the water inlet water source of the washing machine through the water inlet pipe 17, and the water inlet pipe 17 is provided with a constant volume box. 40. When the water level in the fixed volume box 40 reaches a high water level, the water inlet of the fixed volume box 40 is closed, the water outlet is opened, and water is fed into the inner cylinder 1; when the water level in the fixed volume box 40 reaches a low water level, the water in the fixed volume box 40 The water inlet is opened and the water outlet is closed; the water level corresponding to the inner cylinder can be obtained by detecting the opening times of the water outlet of the constant volume box 40 .

[0051] like figure 1 As shown, in this embodiment, the constant volume box 4...

Embodiment 2

[0059] In this embodiment, a method for controlling a washing machine is introduced. The water source of the washing machine flows into the constant volume box, and by controlling the valve body set in the constant volume box, the constant volume box can store water to a high water level, and then the constant volume box is stored in the constant volume box. The water is discharged into the inner cylinder until the water level of the constant volume box reaches the low water level, and the number of times of drainage of the constant volume box is counted to obtain the water inlet water level of the inner cylinder of the washing machine.

[0060] In this embodiment, the specific steps of the washing machine control method are as follows:

[0061] Step 1. Feed water into the inner tub of the washing machine from the water inlet pipe of the washing machine;

[0062] Step 2. The water inlet of the constant volume box is opened, the water outlet is closed, and the water inlet of th...

Embodiment 3

[0072] In this embodiment, in order to realize the sealing of the inner cylinder opening 101 when the washing machine is in operation, the following settings are made:

[0073] like figure 1 and figure 2 As shown, a washing machine, a door cover 4 is installed on the washing machine shell 2, and the door cover 4 is relatively rotatably connected with the inner cylinder cover 8 through the elastic mechanism, so that the elastic mechanism provides the inner cylinder cover 8 after the door cover 4 is closed. Lock the elastic force, make the inner cylinder cover 8 and the inner cylinder cylinder mouth 101 in sealing contact, and make the inner cylinder cover 8 rotate together with the inner cylinder 1, so as to realize that the inner cylinder cover 8 is buckled to the inner cylinder cylinder mouth 101 after the door cover 4 is closed. The purpose of sealing the inner cylinder 1.

[0074]Through the above arrangement, to achieve the sealing of the inner cylinder cover pressed by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com