a washing machine

A washing machine and washing machine shell technology, which is applied in the field of washing machines, can solve the problems of how to seal the mouth of the cylinder and enter the water, and achieve the effects of clear design concept, increased volume, and improved washing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

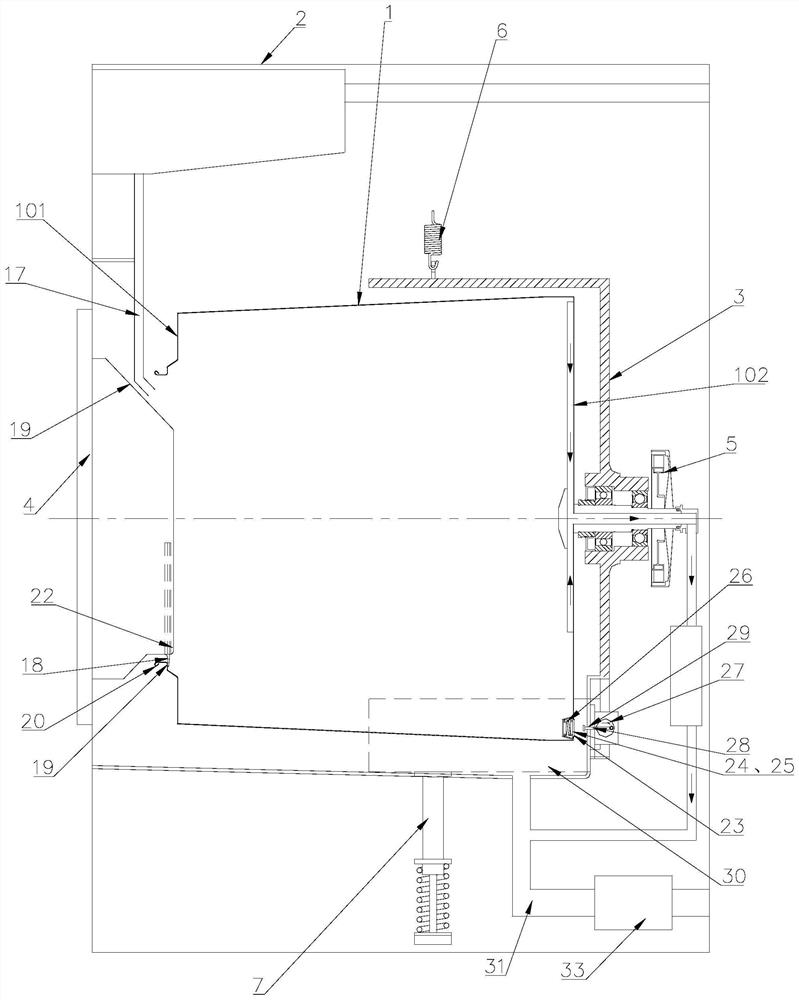

[0046] In this embodiment, in order to feed water into the inner cylinder of the washing machine and realize the sealing of the inner cylinder mouth 101 during the working process of the washing machine, the following settings are made:

[0047] like figure 1 As shown, a water inlet structure of a washing machine, a door cover 4 is installed on the washing machine shell 2, and the door cover 4 is sealed and connected with the lower part of the inner cylinder mouth 101, so that the door cover 4 is fastened to the inner cylinder mouth 101 to realize the inner The lower part of the cylinder 1 is sealed with water; there is a certain gap between the upper end of the door cover 4 and the mouth 101 of the inner cylinder, and the water inlet pipe 17 is connected with the inside of the inner cylinder 1 through the gap, so as to enter the inner cylinder 1 from the upper gap of the door cover 4 water.

[0048] By sealing the lower part of the inner cylinder and setting the upper openin...

Embodiment 2

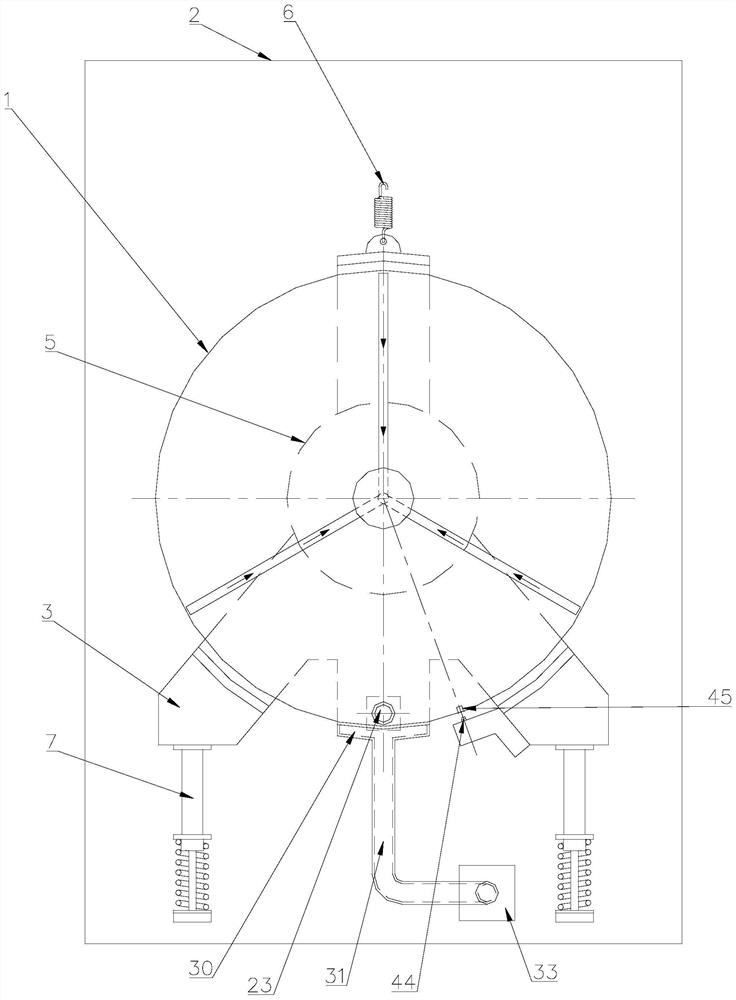

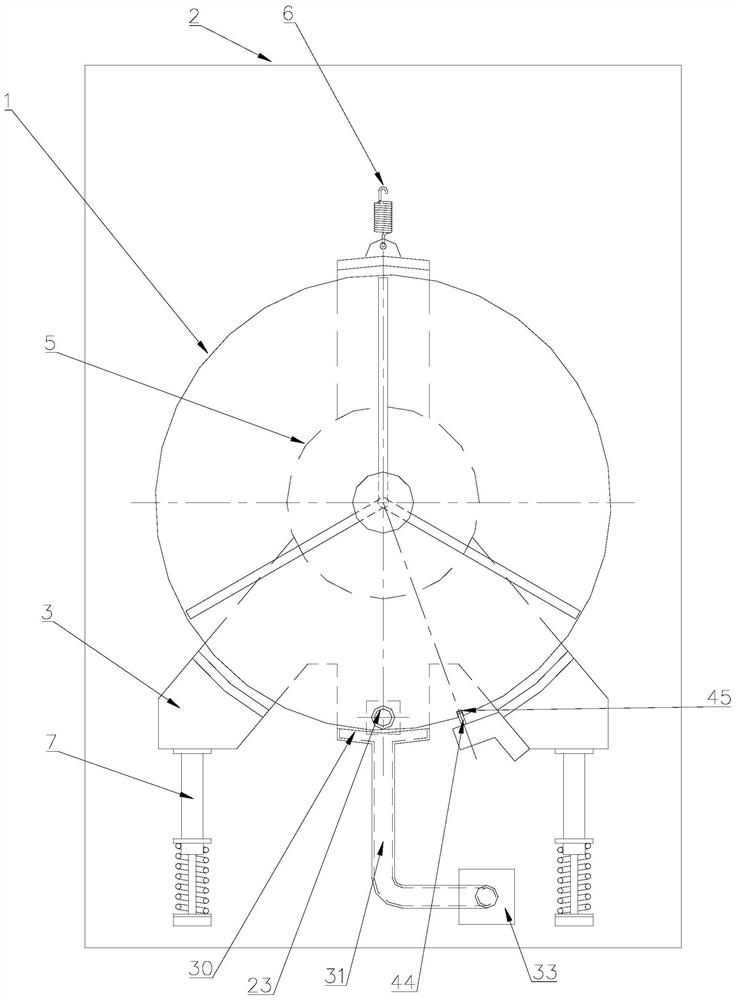

[0060] In the embodiment of the present invention, in order to discharge the water in the inner cylinder of the washing machine, and realize the sealing of the inner cylinder to hold water for normal washing during the working process of the washing machine, the following settings are made:

[0061] like Figure 1 to Figure 5 As shown, a drainage structure of a washing machine, an inner tube 1 is installed in the washing machine shell 2, and a drain port 23 is provided on the inner tube 1, and a drain valve 24 in a normally closed state is installed at the drain port 23; the washing machine is provided with Rotate the inner cylinder 1 to a fixed drainage position and fix the positioning locking mechanism; the washing machine is provided with a spool opening mechanism that opens the drain valve 24 after the inner cylinder 1 is rotated to a fixed drainage position, so that when the washing machine is in the drainage state, the inner cylinder 1 After rotating to a fixed drain pos...

Embodiment 3

[0076] The difference between this embodiment and Embodiment 2 is that the valve core opening mechanism includes an electromagnet installed on the inner tube support 3, and the electromagnet is set corresponding to the drain valve 23, so that the inner tube 1 rotates to a fixed position. In the drain position, the drain valve 23 and the electromagnet are in the coaxial direction; the spool 25 of the drain valve 23 is equipped with a magnet or the spool is entirely made of magnets, so that the electromagnet provides electromagnetic repulsion to the spool 25 after the electromagnet is energized to push the valve. The core 25 moves toward the inner side of the inner cylinder 1 to open the drain valve 23 to drain water.

[0077] During the normal washing process of the washing machine, the drain valve is closed, the inner cylinder rotates normally, and the water in the inner cylinder will not flow out from the drain outlet, and the clothes are washed normally; The iron provides a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com