PET preform wall thickness measuring device

A technology of wall thickness measurement and preform, applied in the direction of mechanical thickness measurement, etc., can solve the problems of high measurement requirements, poor anti-electromagnetic interference ability, poor measurement accuracy, etc., and achieve the effect of mutual compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

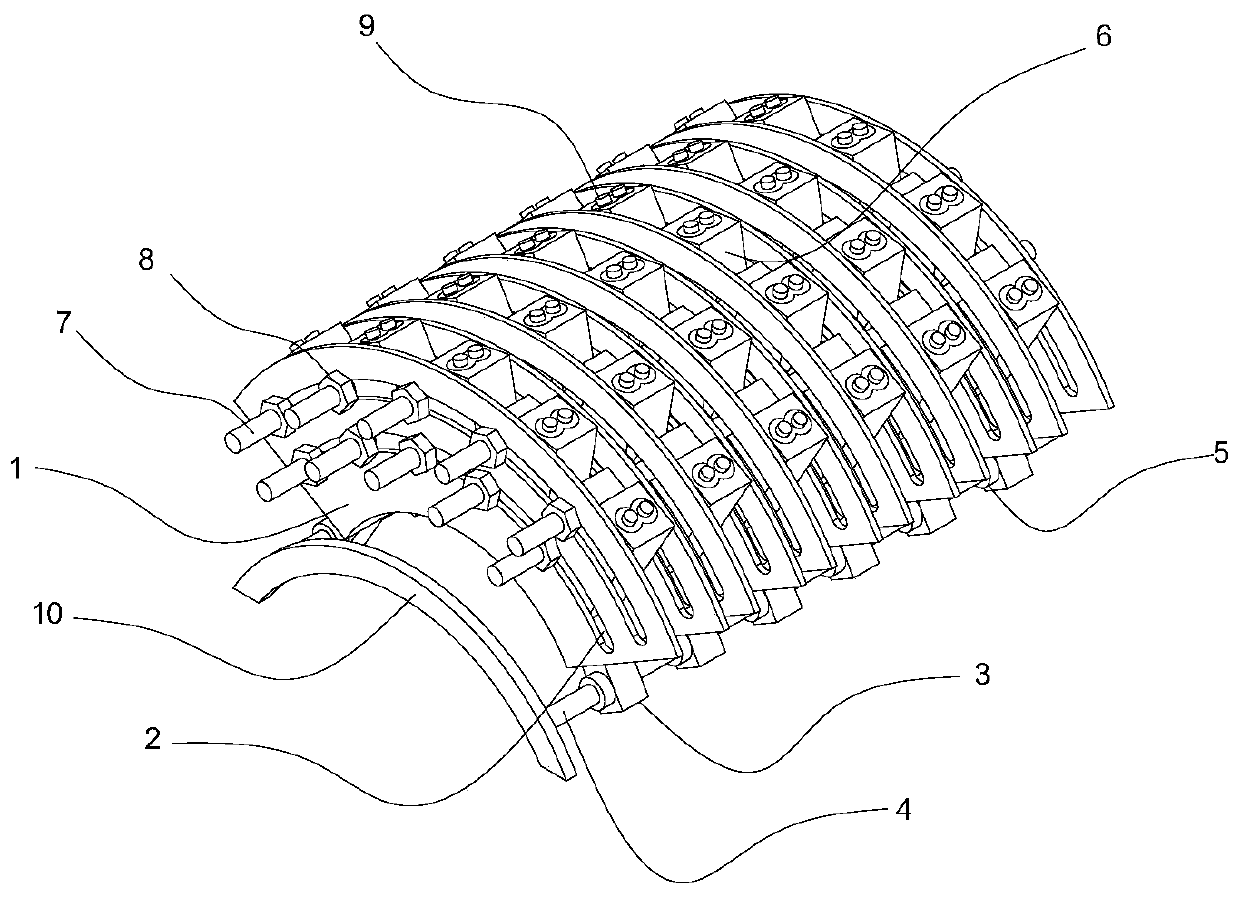

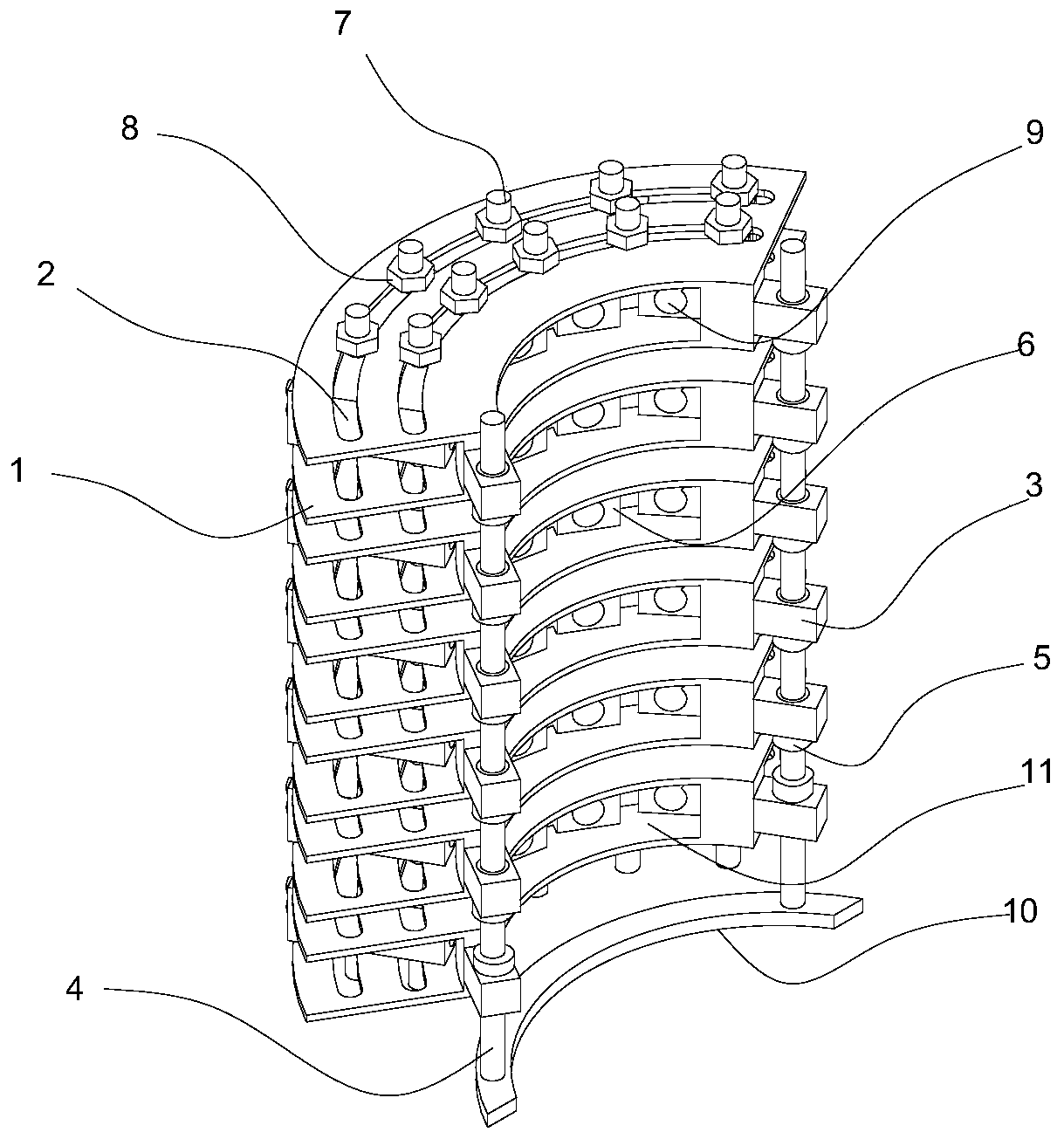

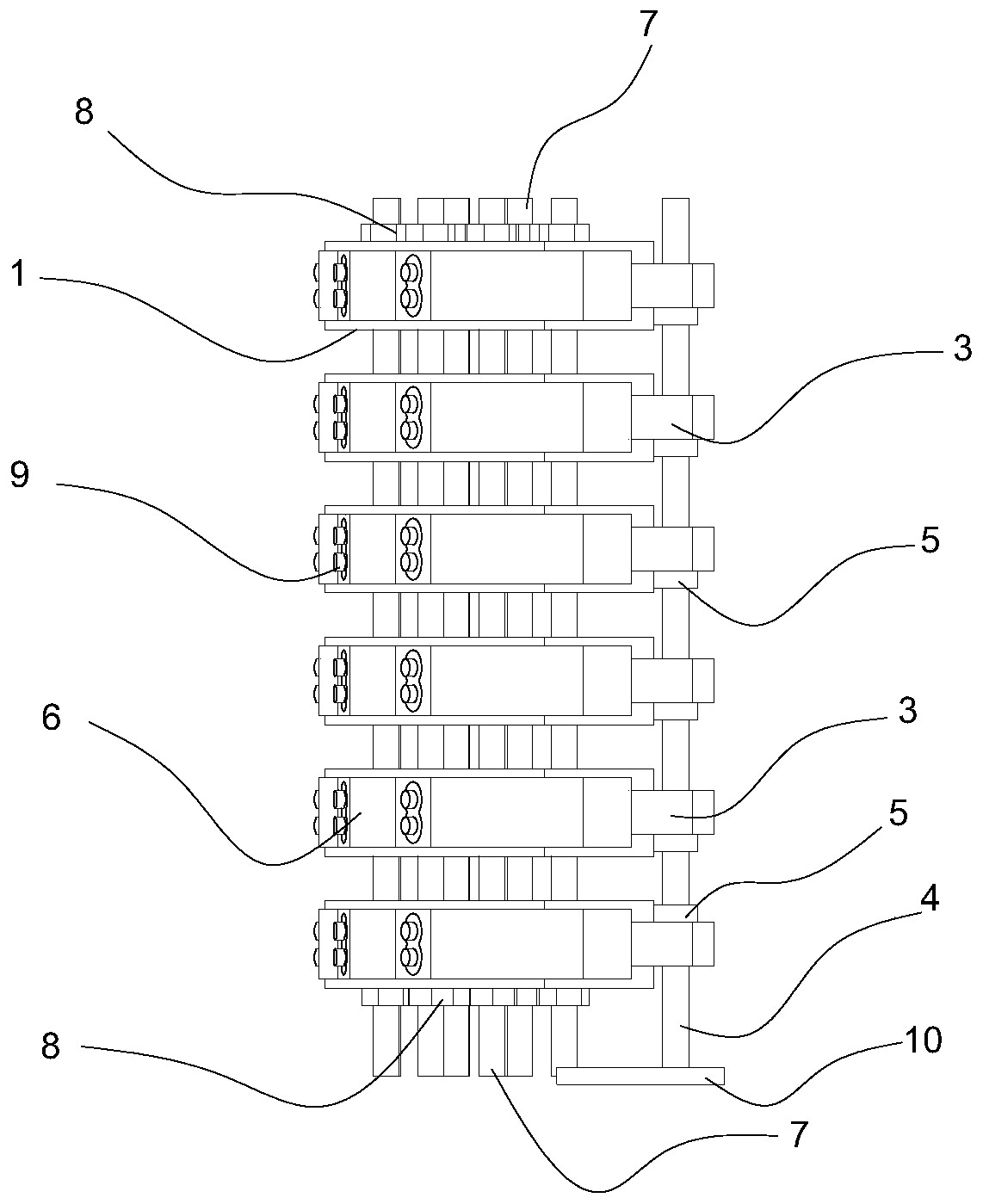

[0023] Such as Figure 1 to Figure 7 As shown, the PET preform wall thickness measuring device of the present invention includes an optical fiber fixing device and a Y-shaped optical fiber 9; the optical fiber fixing device includes a curved bottom plate 10, a curved installation chute 1, an angle adjustment shaft 7, a lock Tighten the nut 8, and the two ends of the arc-shaped bottom plate 10 are provided with an adjustment shaft 4;

[0024] The two ends of the arc-shaped installation chute 1 are provided with connecting blocks 3; the adjustment shaft 4 is equipped with at least three arc-shaped installation chutes 1; the two ends of the arc-shaped installation chute 1 are provided with connecting blocks 3. The bottom of the arc-shaped installation chute 1 has an opening 11; the connecting block 3 is provided with a through hole, and a bushing 5 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com