Intelligent quality monitoring device for bearing ring

A technology for quality monitoring and bearing rings, applied in electromagnetic measuring devices, mechanical diameter measurement, electric/magnetic diameter measurement, etc., can solve problems such as high instrument cost, many auxiliary equipment, and inconvenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

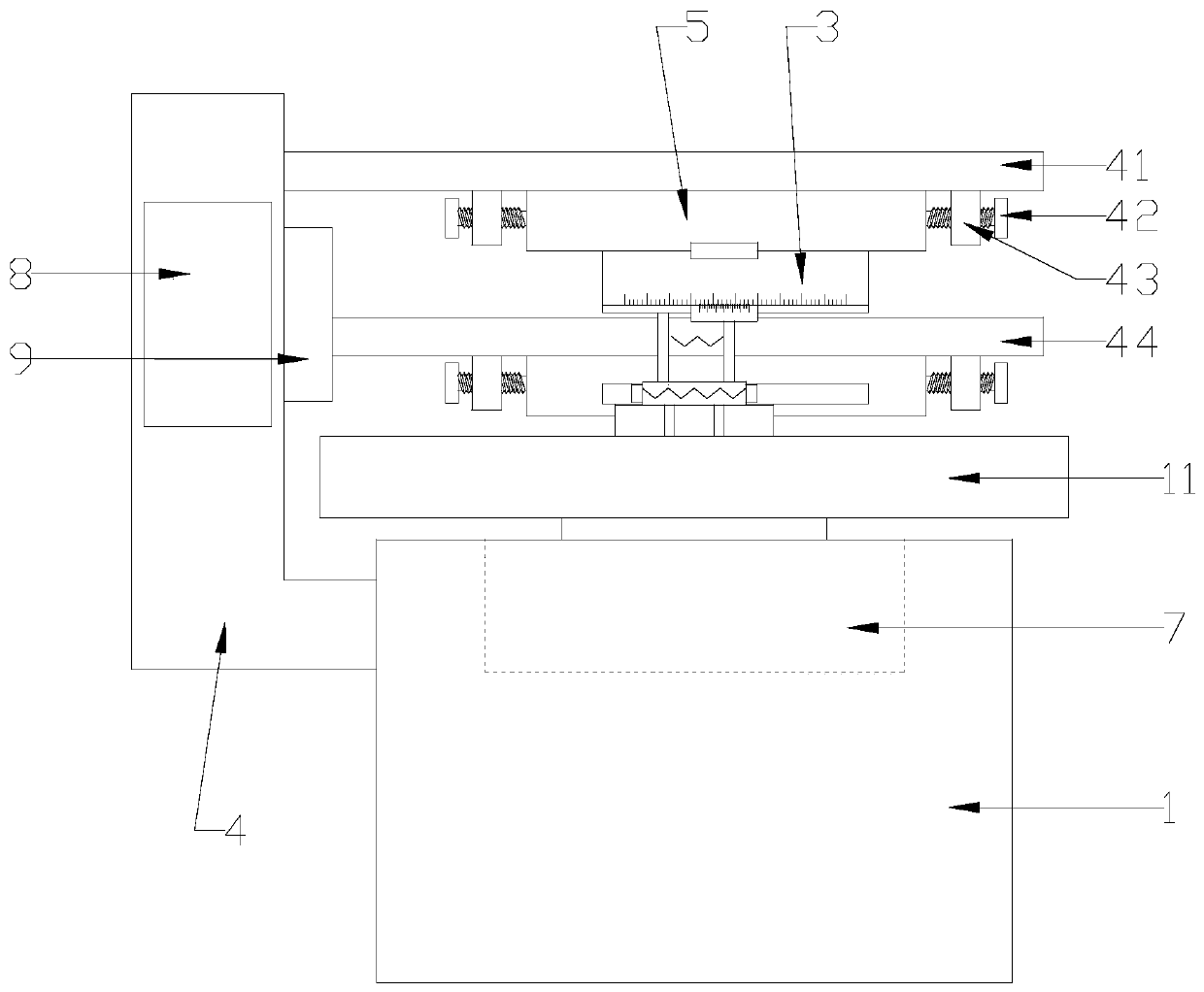

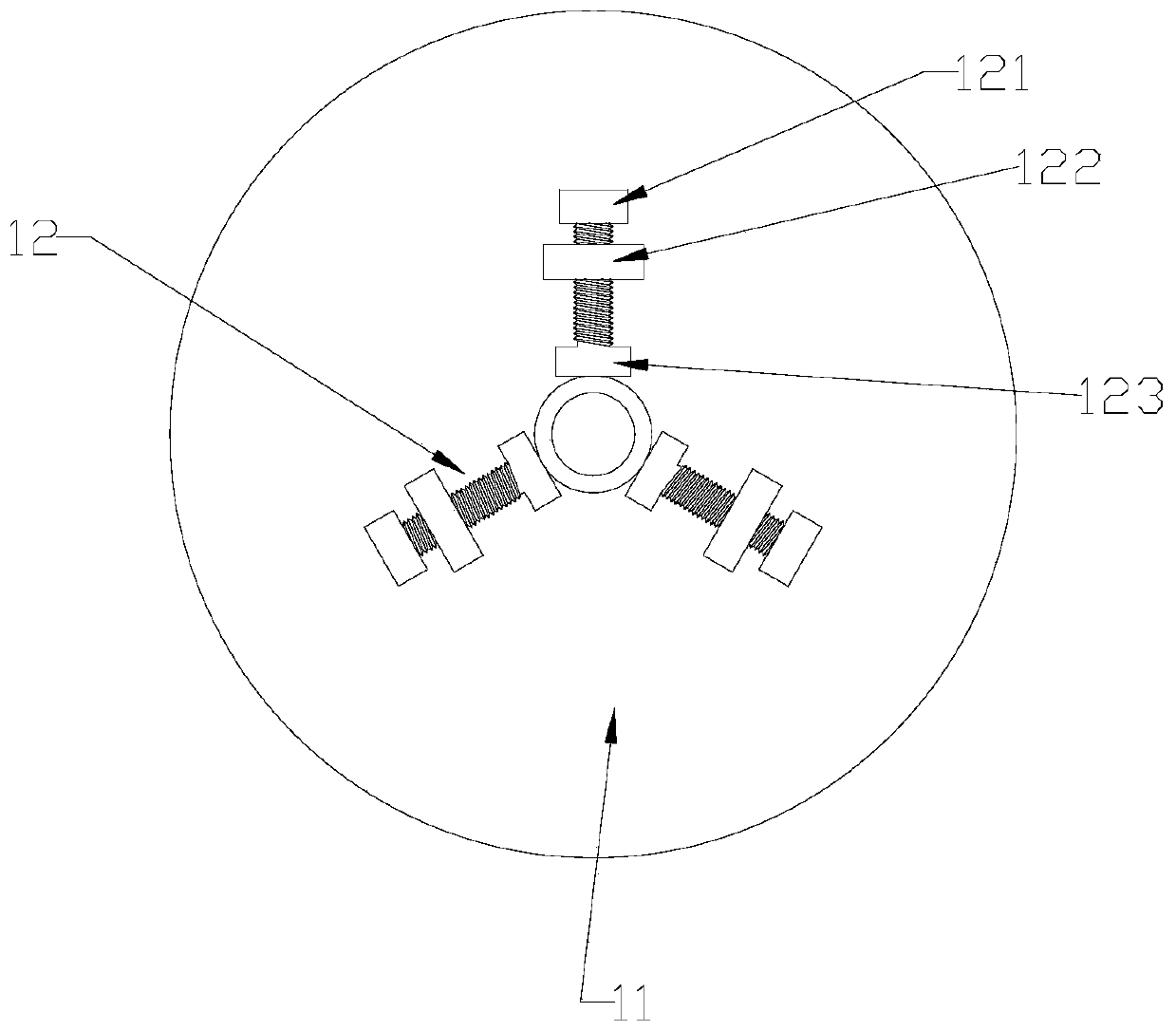

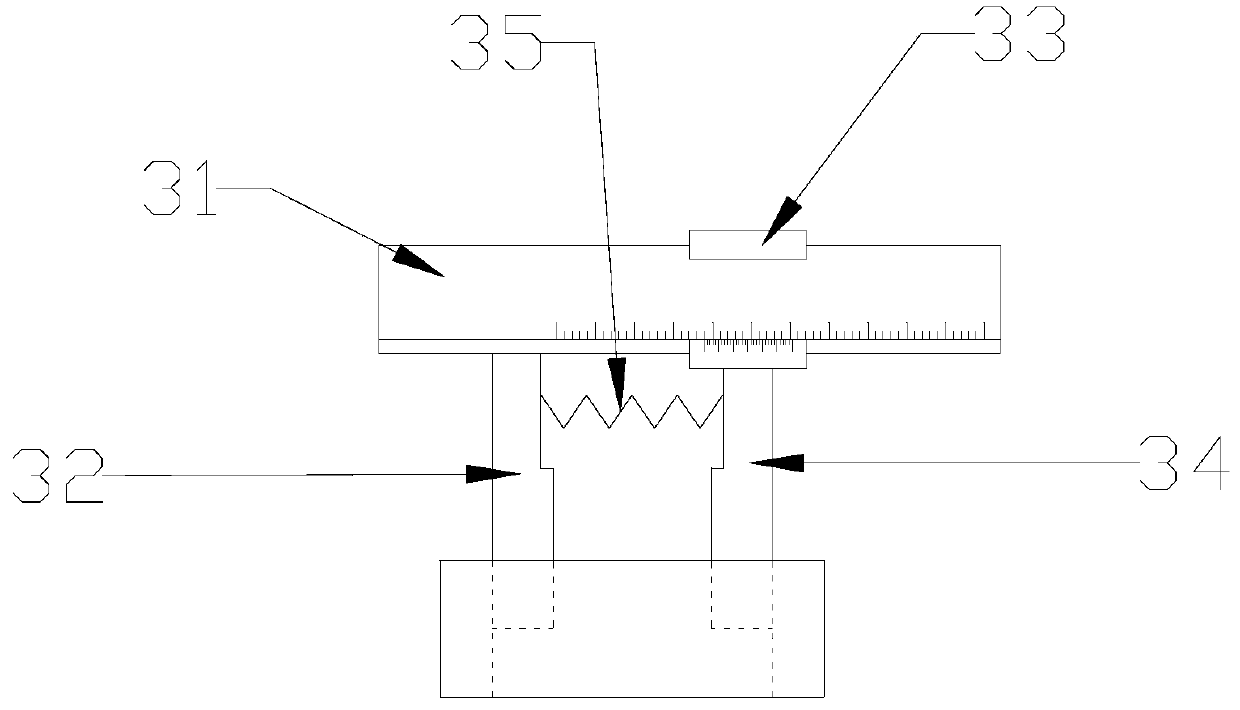

[0016] refer to Figure 1 to Figure 4 , a quality monitoring device for intelligent bearing rings of the present invention, comprising a chassis 1, a support frame 4 fixed on one side of the body of the chassis 1, a motor 7 that drives the top turntable 11 of the chassis 1 to rotate, and is fixed up and down on the turntable through the support frame 4 11 above the two groups of measurers, and the display screen 8 and controller 9 fixed on the support frame 4, the top center of the turntable 11 is provided with several groups of clamps 12, the measurer includes a resistance box 5 and Caliper 3, said caliper 3 comprises main ruler 31, fixed and auxiliary ruler 32 fixed at one end of main ruler 31, movable and auxiliary ruler 34 moving along main ruler 31 through sliding sleeve 33, fixed and auxiliary ruler 32 and movable and auxiliary ruler The spring 35 between 34, the main scale 31 and the sliding sleeve 33 are respectively provided with length scales, the main scale 31 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com