Water-cooled motor seat

A motor base and water-cooling technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of affecting the service life of the motor, unsatisfactory fixing effect, and easy vibration of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0030] In the present invention, in the absence of a contrary statement, the orientation words included in the term, such as "upper, lower, inner, outer", etc., only represent the orientation of the term in the normal use state, or are understood by those skilled in the art. colloquial term and should not be construed as a limitation of the term.

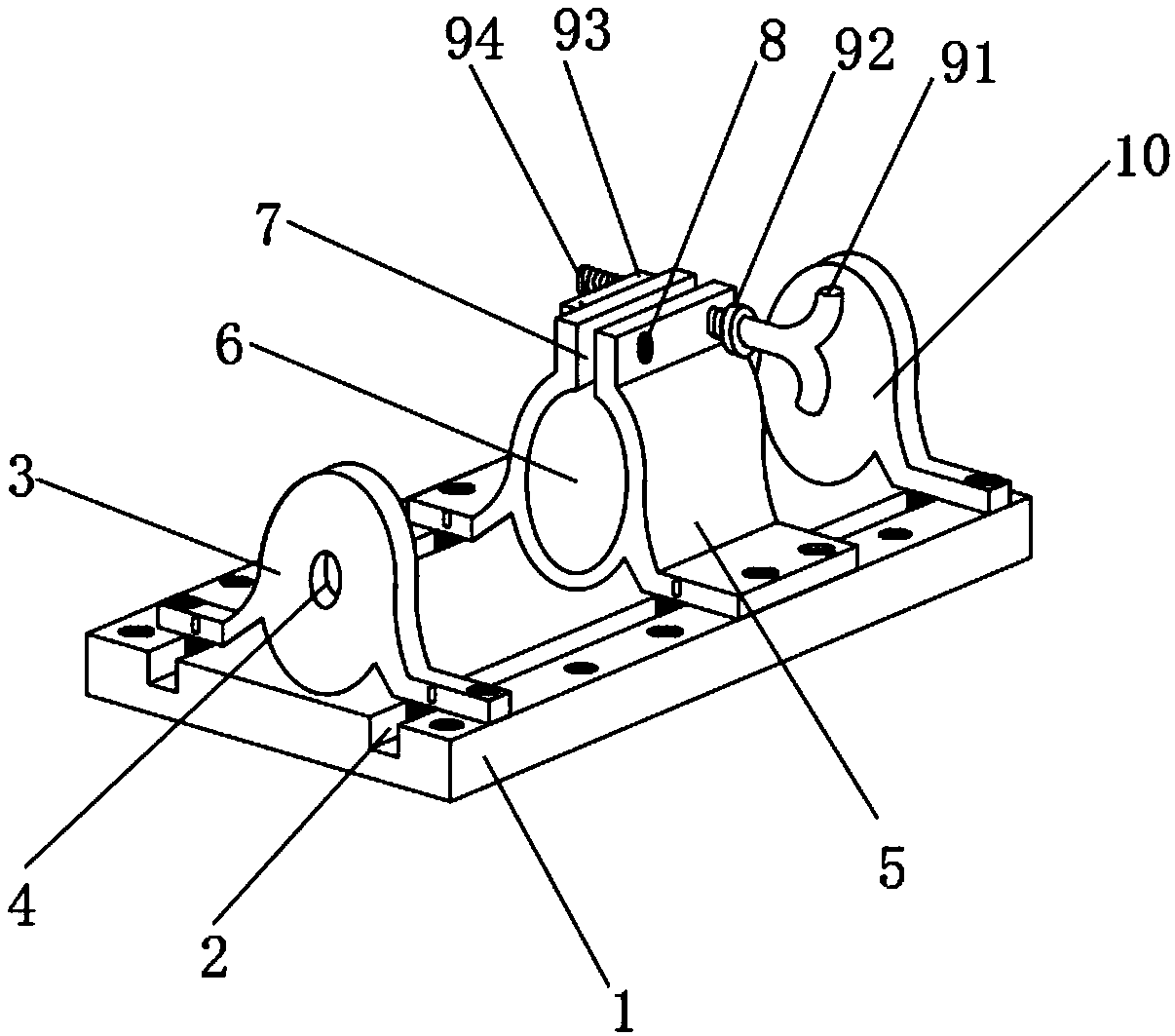

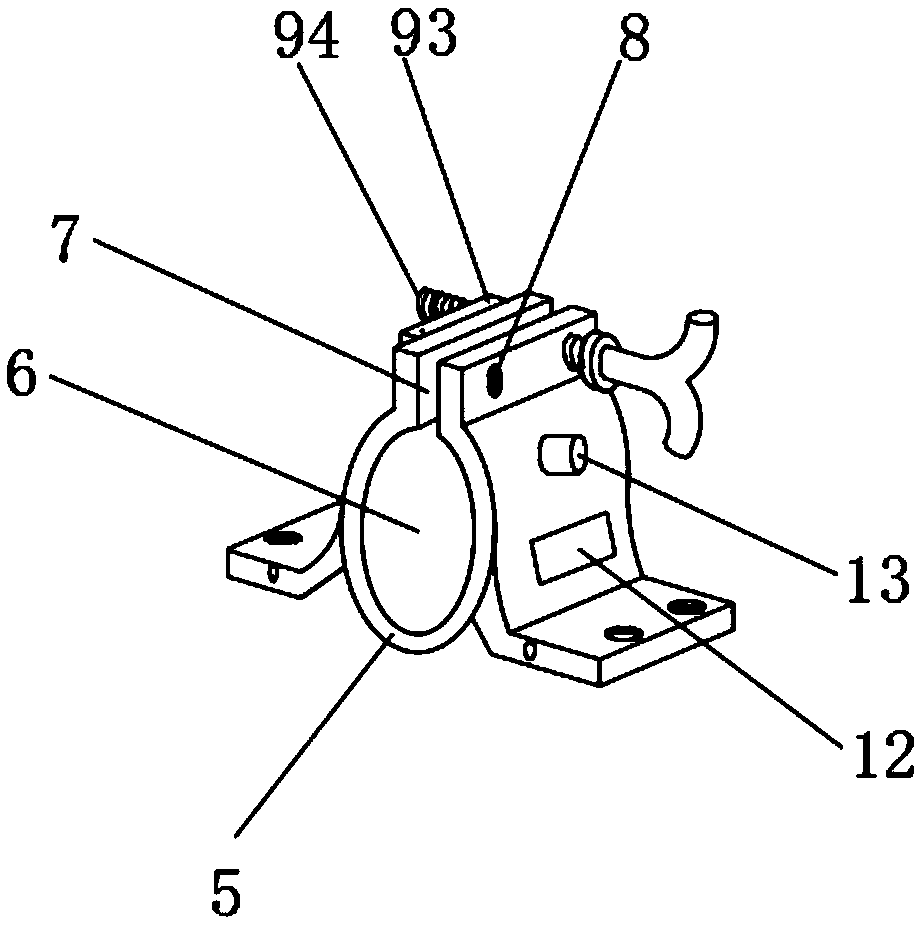

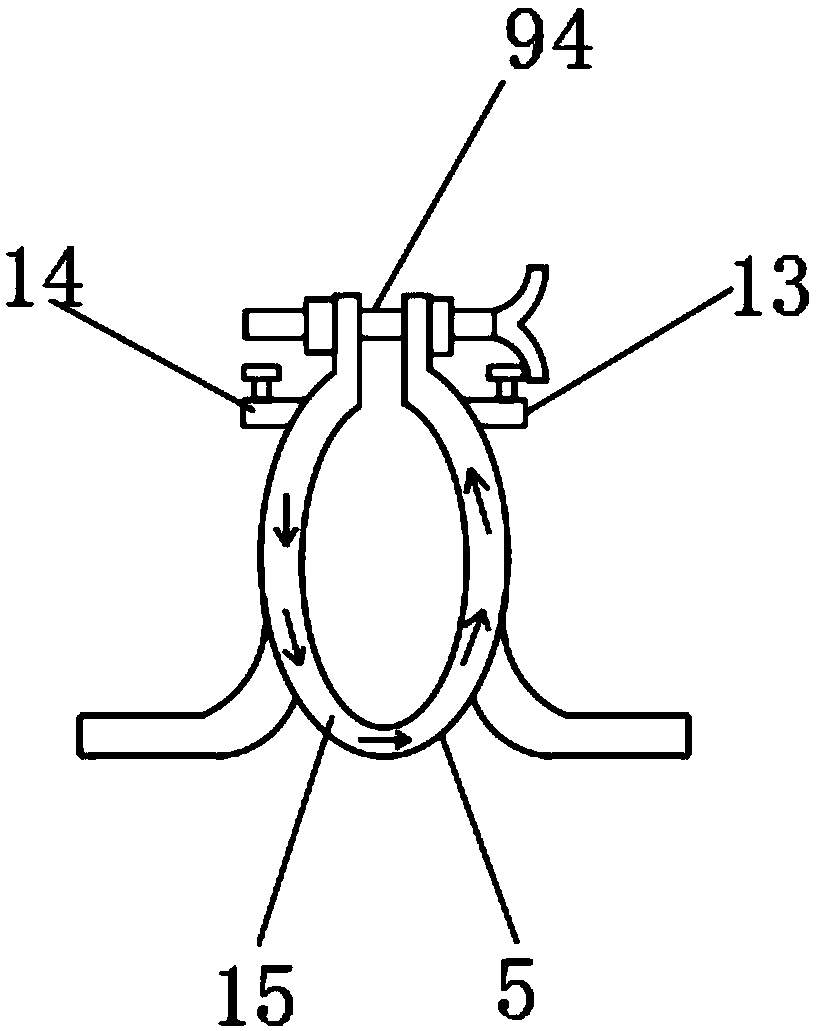

[0031] Such as Figure 1-3 As shown, the present invention provides a water-cooled motor base, which includes: a base 1, a fixed base 5, an adjustment rod, a fixed front cover 3 and a fixed rear cover 10; the upper surface of the base 1 is along the There are at least two parallel slide grooves 2 along its own lengt...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap