Internal-expanding hollow cylinder clamp with rolling wheel

A hollow cylinder, internal tensioning technology, applied in the direction of expanding the mandrel, etc., can solve the problems of easy separation of the cylinder, reduction of the friction block and the clamping force of the cylinder, and loosening of the cylinder, so as to achieve good clamping. Effect, stable and powerful clamping, convenient release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

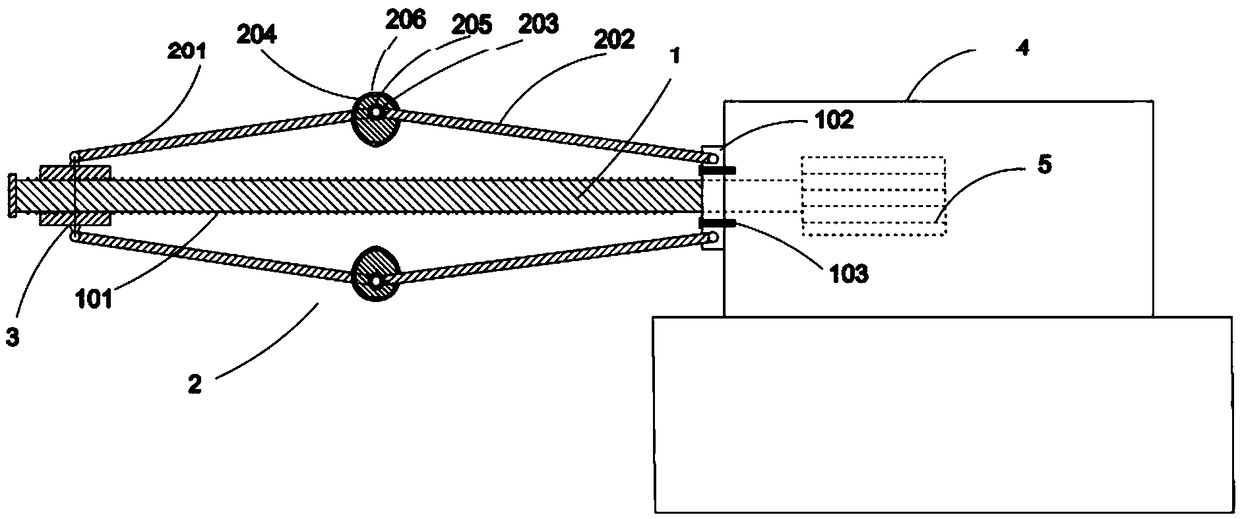

[0025] like figure 1 , 2 As shown, an inner-stretching hollow cylinder clamp with a roller includes: a main shaft 1, a fastener 2, a looper 3, and the looper is provided with an internal thread and is sleeved on one side of the main shaft;

[0026] The main shaft 1 is provided with an external thread 101 that matches the inner thread of the looper, and a fixed plate 102 is vertically arranged on one end of the main shaft 1 relative to the looper 3;

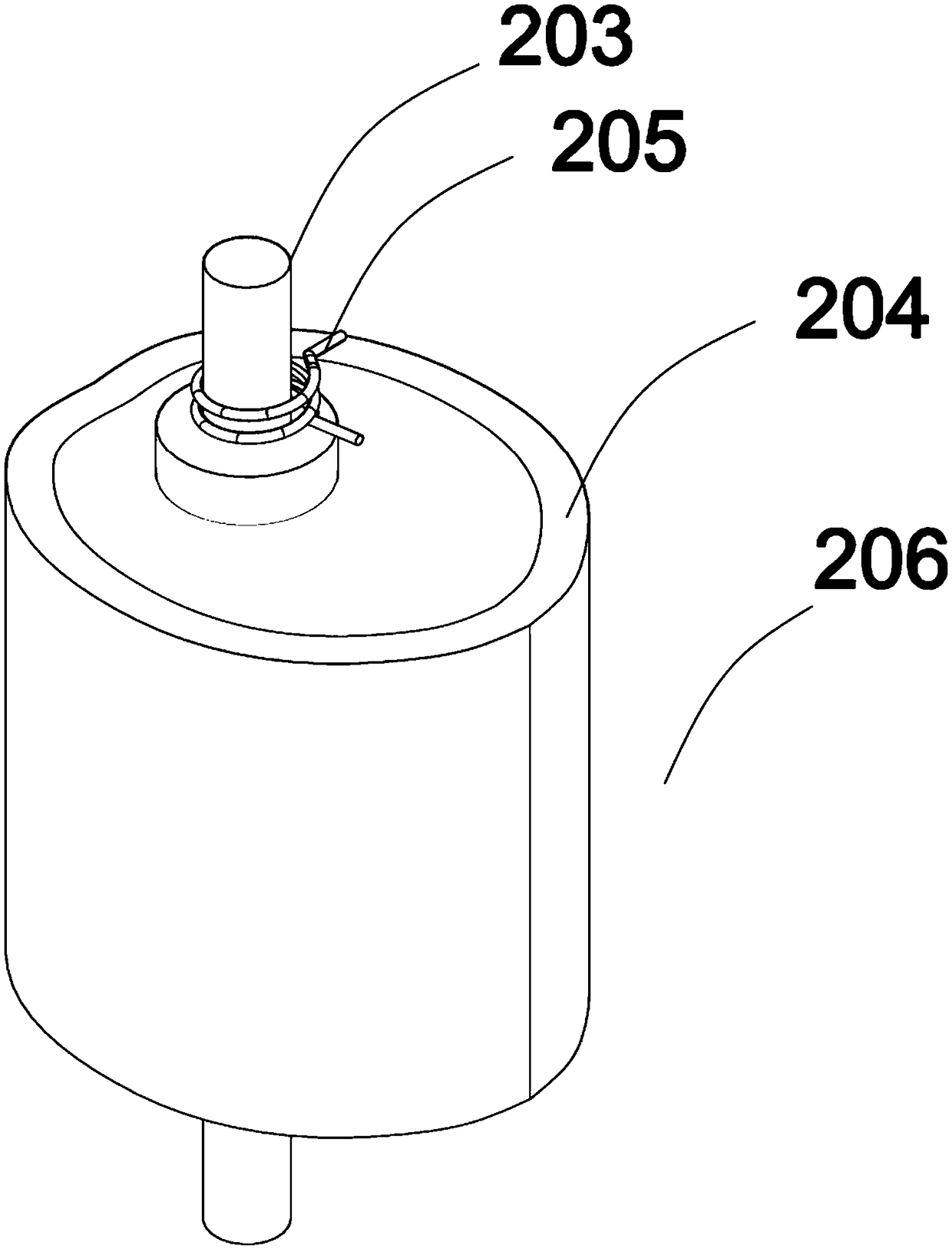

[0027] The fastener 2 includes a connecting rod, a rotating shaft 203 and a tightening roller 206. The connecting rod includes a first connecting rod 201 and a second connecting rod 202. One end of the first connecting rod 201 is connected to the rotating shaft and the other end is The fixed plate 102 is connected to the hinge; one end of the second connecting rod 202 is connected to the hinge of the rotating shaft, and the other end is connected to the hinge of the looper 3. The cross-section of the tightening roller 206 is in t...

Embodiment 2

[0037] When the spindle 1 rotates clockwise, the looper approaches the fixing plate 102 along the thread, the tightening roller 206 is lifted, and the workpiece is clamped; when the spindle 1 rotates counterclockwise, the looper moves away from the fixing plate along the thread. The disc 102, the tightening roller 206 descend, and the workpiece is released.

[0038] During the cutting process of the workpiece, due to the self-weight of the barrel, machining vibration, workpiece movement, temperature rise, etc., the clamped part of the barrel is loose or deformed. At this time, the tightening roller 206 is provided on the sulfur-free hard rubber layer 204. It rotates with the workpiece under the frictional force, so that the tension of the inner tension hollow cylinder clamp increases, the frictional force on the inner wall of the workpiece increases, and the workpiece is prevented from loosening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com