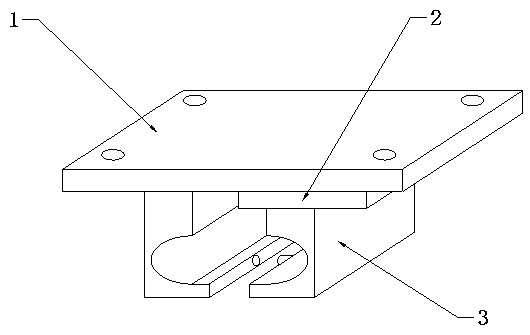

Simple industrial mechanical clamp tool

An industrial machine, simple technology, applied in the direction of manipulator, chuck, metal processing, etc., can solve the problems of damage to tubular parts, affecting the processing progress, poor clamping effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

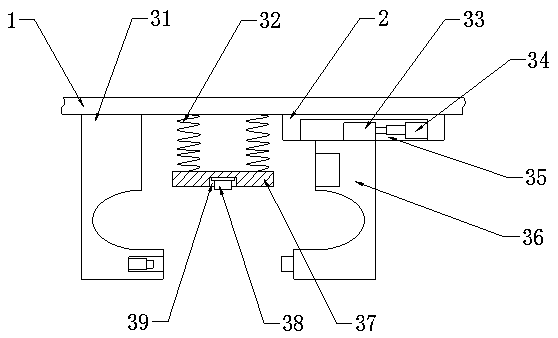

[0020] Specific implementation method: when in use, the user first uses the external fixing bolts to fix the fixed plate 1, and then the user operates the external device to make the fixed plate 1 move downward, and the downward movement of the fixed plate 1 drives the fixed block 2, the spring 32 and the fixed plate 1. Slot plate 31 moves downwards, and fixed block 2 moves downwards and drives slide block 33 to move downwards, and fixed block 2 moves downwards and drives mobile groove plate 36 to move downwards, and spring 32 moves downwards to drive magnetic plate 37 to move downwards, and the magnetic plate 37 moves downwards. The downward movement of the plate 37 drives the electric cylinder open switch 38 to move downward. When the magnetic plate 37 moves downward to the upper side of the tubular part, the tubular part moves upward under the magnetic attraction force of the magnetic plate 37 and triggers the electric cylinder open switch 38. Then the electric cylinder 34 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com