Cylinder sleeve demounting device high in safety performance

A technology of safety performance and disassembly device, which is applied in the field of cylinder liner disassembly device with high safety performance, can solve the problems of easily damaged cylinder liners, and achieve the effect of avoiding damage to cylinder liners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

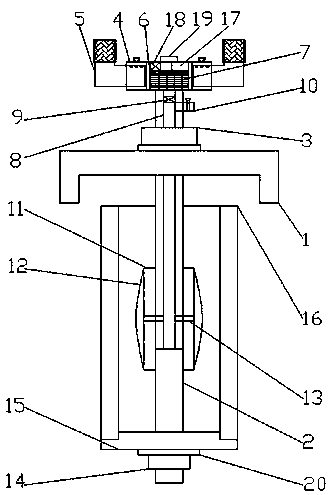

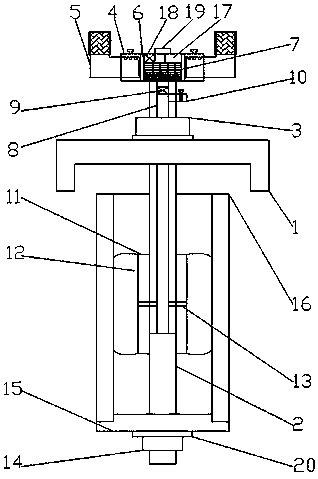

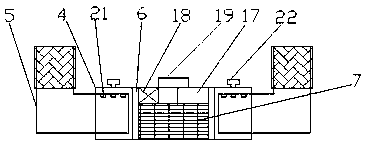

[0019] Such as Figure 1-3 As shown, the present invention provides a cylinder liner removal device with high safety performance, including a bracket 1, the center of the bracket 1 runs through the main screw 2, the bracket 1 and the main screw 2 are fixed by the upper nut 3, and the top of the main screw 2 A crossbar 4 is provided, and one end of the crossbar 4 is connected to the telescopic rod 5. The middle part of the interior cavity of the crossbar 4 is provided with a placement chamber 6. The bottom of the placement chamber 6 is provided with a micro blower 7, and the bottom of the micro blower 7 is connected to a pipe 8. A one-way valve 9 is provided above the inner cavity of the pipeline 8, an air outlet 10 is provided on one side of the pipeline 8, a sleeve 11 is provided in the middle of the main screw 2, and the outer side of the sleeve 11 wraps a leather bag 12, and the leather bag 12 communicates with the described valve through a thin tube 13. The pipeline 8 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com