Breakwater with good adaptability and method

A breakwater and adaptive technology, applied in the direction of breakwaters, jetties, embankments, etc., can solve the problems that breakwaters cannot withstand bad weather, wind and waves, etc., and achieve the effect of strong blocking ability, high safety and reliability, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

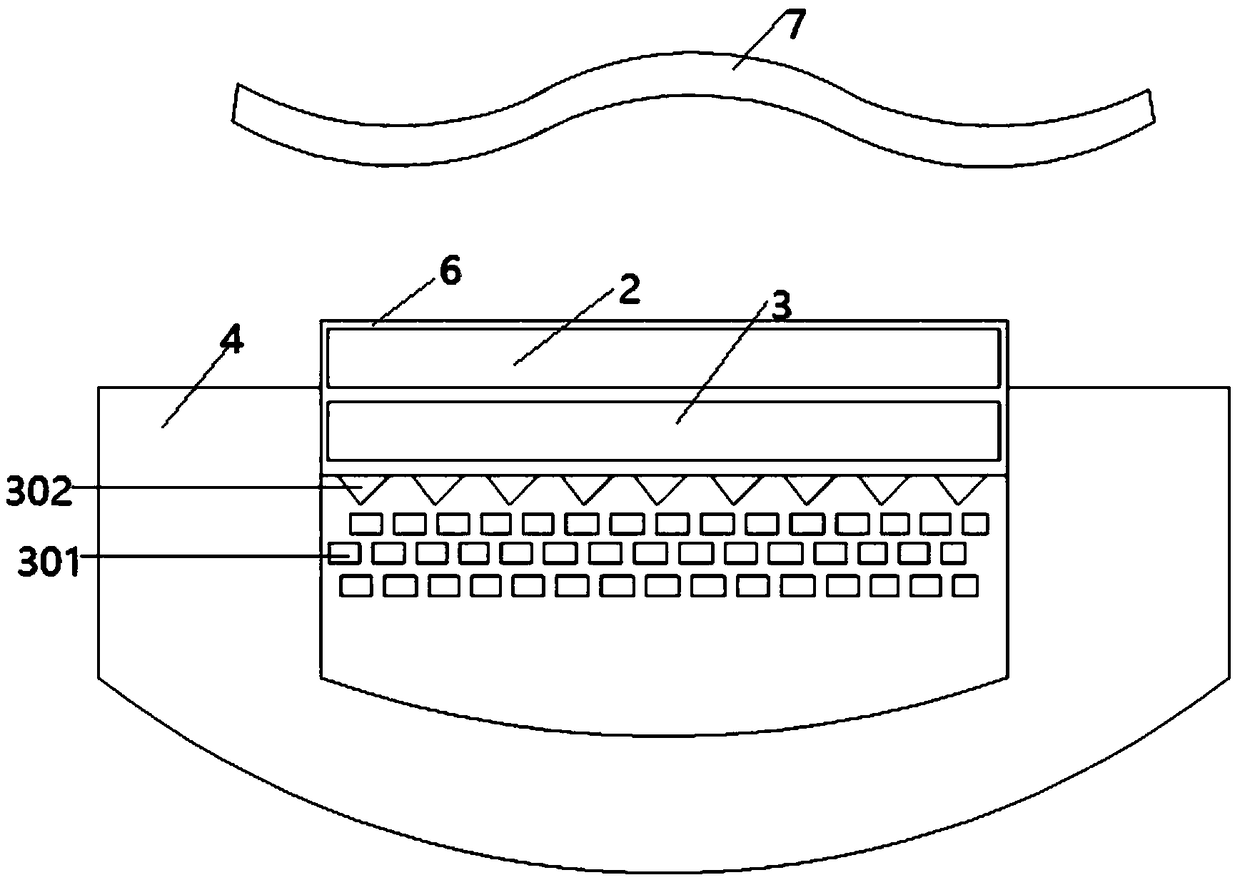

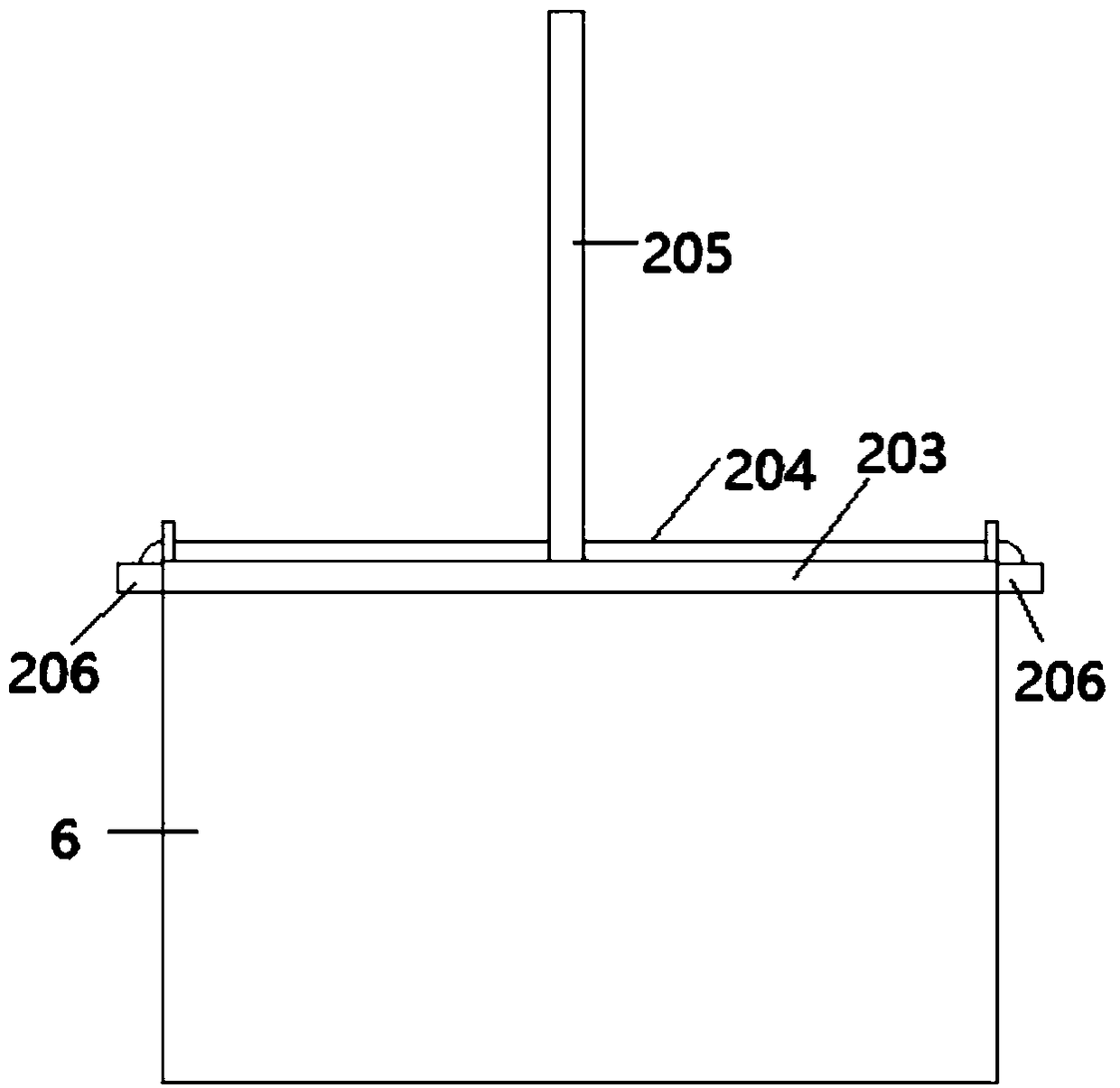

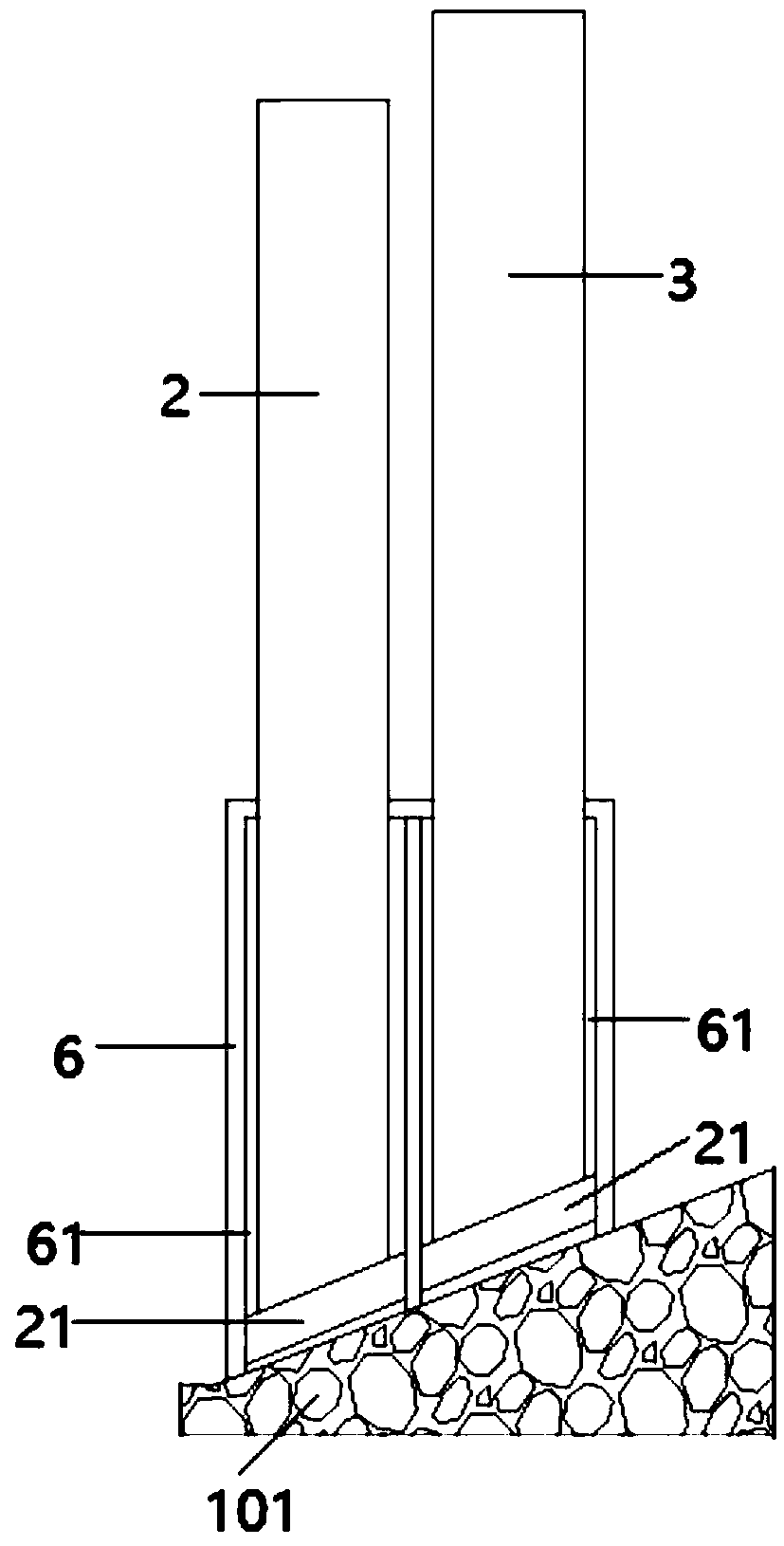

[0036] Such as figure 1 The illustrated embodiment is a breakwater with good adaptability, comprising a first breakwater wall 2 located on the seashore, a second breakwater wall 3 located behind the first breakwater wall, and set in a groove in the seashore ground The water bag 4 is located on the groove such as Figure 5 The cover plate 5 shown; the cover plate can slide up and down along the inner wall of the groove, such as image 3 As shown, both the first anti-wave wall and the second anti-wave wall are connected with the guide structure 6 located on the coast ground, and the guide structure includes two independent cavities 61 whose upper and lower ends are closed; the first anti-wave wall and the second anti-wave The lower ends of the anti-wave walls extend into two independent cavities respectively, and the lower ends of the first anti-wave wall and the second anti-wave wall are provided with push plates 21, and the two push plates are respectively slid and sealedly c...

Embodiment 2

[0042] Embodiment 2 includes all structure and method parts of embodiment 1, such as Figure 4 As shown, embodiment 2 also includes an auxiliary anti-wave wall 7 located behind the second anti-wave wall, the front surface and the rear surface of the auxiliary anti-wave wall are all wave-shaped; the bottom of the coast is provided with an accommodating groove for the auxiliary anti-wave wall 8. The lower part of the accommodating groove communicates with the air intake pipe 9, and the lower end of the auxiliary anti-wave wall is provided with a piston plate 10 that slides and seals with the accommodating groove, and the air intake pipe is connected with the air pump 303, such as Figure 6 As shown, the air pump is connected to the controller 304, and the controller is connected to the server 305 for data.

[0043] Also include the following steps:

[0044] The server obtains real-time weather forecast information through the Internet. If the weather forecast predicts that ther...

Embodiment 3

[0048] Embodiment 3 includes all the structure and method parts of Embodiment 1. Each wave-dissipating block of Embodiment 3 is provided with a plurality of air outlets, and each cavity is connected to the pressure tank through a trachea, and the front surface of the guide structure is provided with 10 shock sensors 306, the pressure tank is provided with a solenoid valve 307, such as Figure 6 As shown, each shock sensor and solenoid valve are electrically connected to the controller.

[0049] Each vibration sensor detects the vibration signal. When the vibration amplitude value detected by any vibration sensor is greater than the vibration threshold value W set in the controller, the controller controls the solenoid valve to open, and the gas flows out from the pressure tank; the gas forms bubbles in the water, The seawater is vaporized, and the impact of the gas offsets part of the impact of the waves;

[0050] When the vibration amplitudes detected by each vibration senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com