Method and apparatus for measuring molecular weight of gas

A technology of molecular weight and gas, applied in the direction of specific gravity measurement, measuring device, using sound wave/ultrasonic wave/infrasonic wave to analyze fluid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

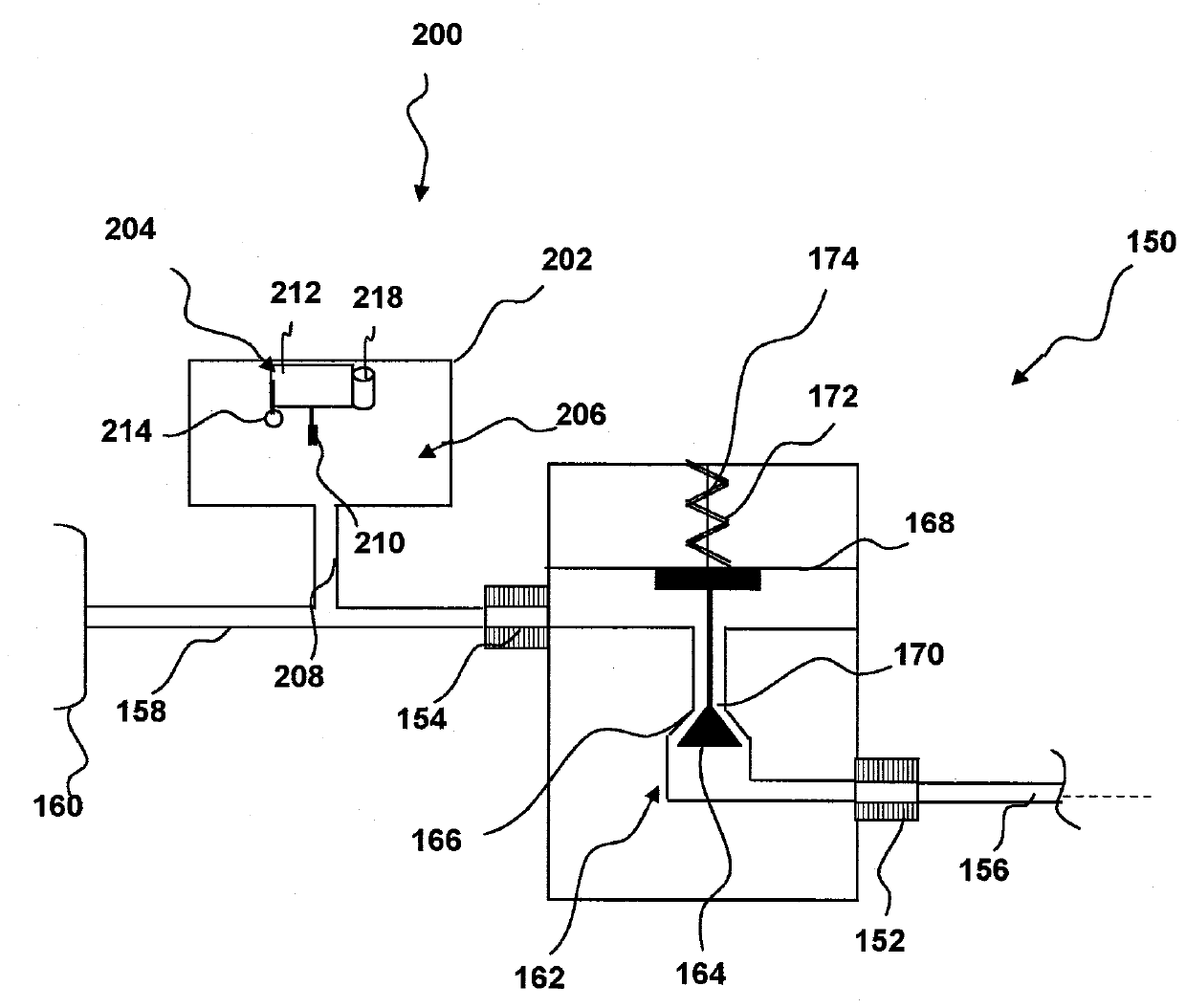

[0071] figure 1 A schematic diagram of a gas canister assembly 10 according to an embodiment of the present invention is shown.

[0072] figure 1 A schematic diagram showing a situation in which the invention can be used. A gas tank 100, a regulator 150, and a molecular weight meter 200 are provided.

[0073] The gas tank 100 has a gas tank body 102 and a valve 104 . The gas tank body 102 comprises a generally cylindrical pressure vessel having a flat base 102a arranged to enable the gas tank assembly 10 to stand freestanding on a flat surface.

[0074] The gas tank body 102 is formed from steel, aluminum, and / or composite material, and is adapted and arranged to withstand internal pressures of up to about 900 bar (gauge). Orifice 106 is located at the proximal end of gas canister body 102 opposite base 102a and includes threads (not shown) adapted to receive valve 104 .

[0075] Gas tank 100 defines a pressure vessel having an internal volume V. As shown in FIG. Any sui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com