Connecting system for dust removal cloth bag fixation

A connection system and cloth bag technology, which are used in the separation of dispersed particles, chemical instruments and methods, and dispersed particle filtration, etc., can solve the problems of bag cap cracking, mutual abrasion and falling off of the hook and spring, and avoid loosening and falling off. Guarantees a firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

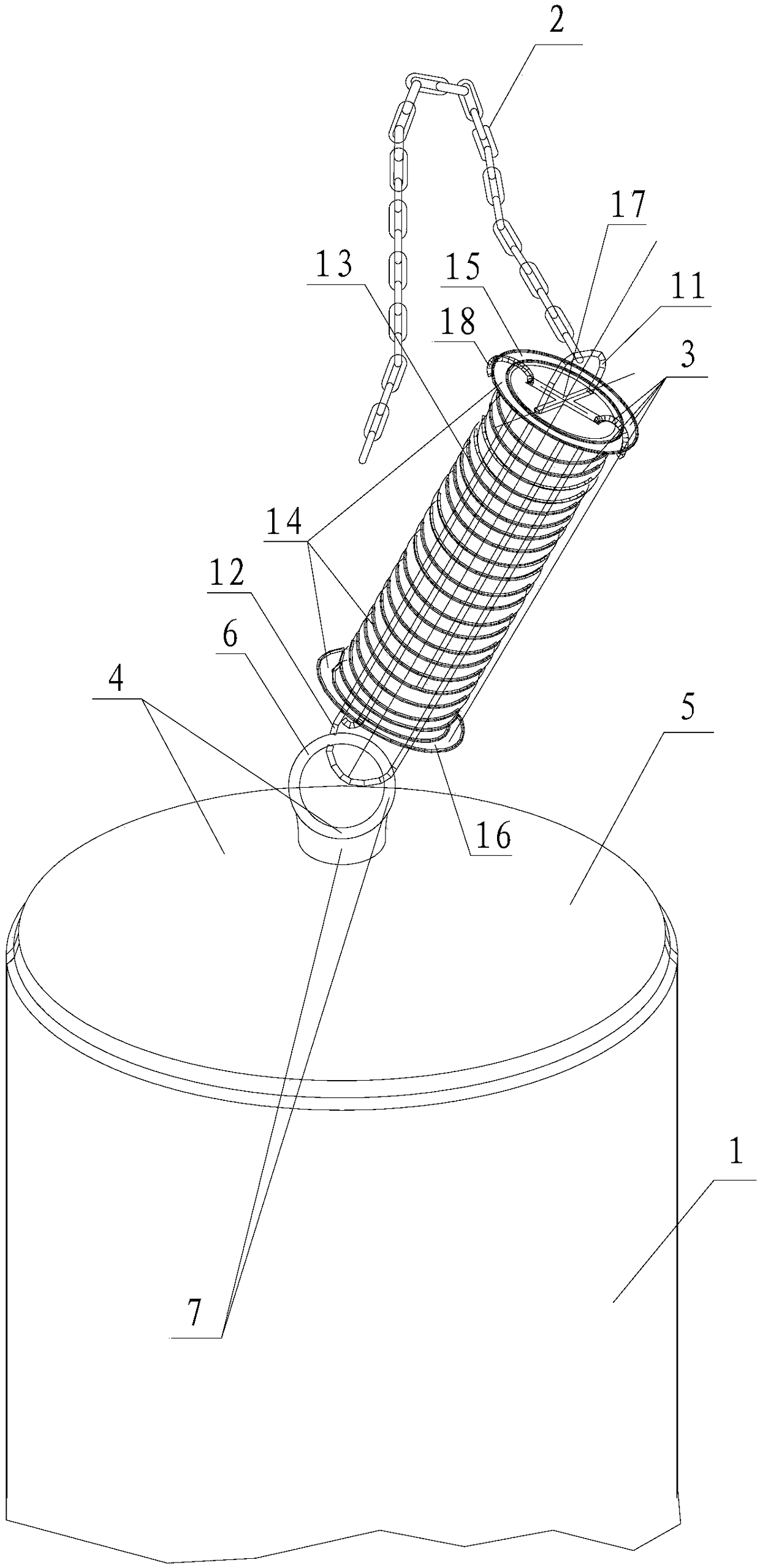

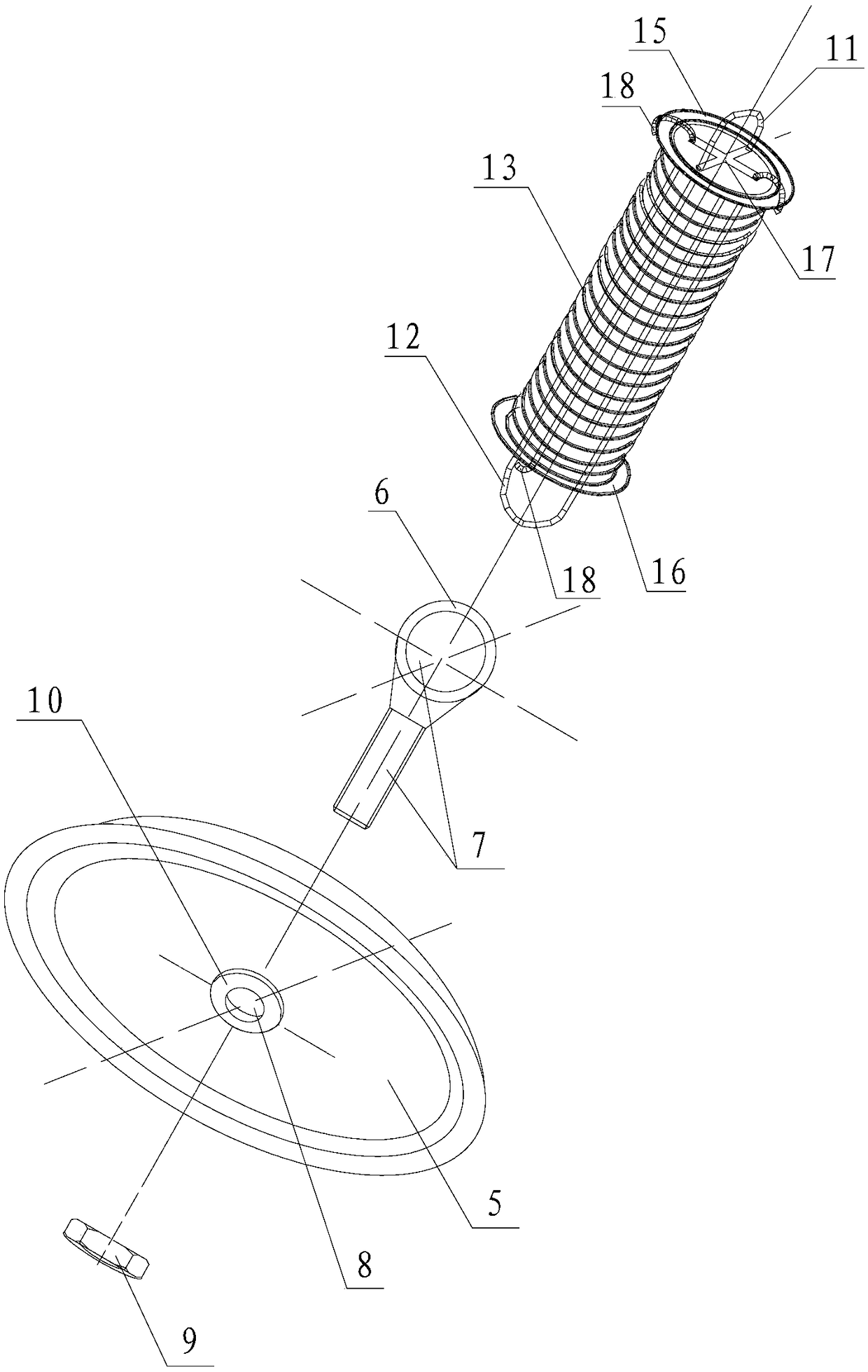

[0016] Such as figure 1 , figure 2 Shown is a connection system provided by the present invention that is firmly connected and is not easy to loosen and fall during operation, and is used for fixing the dust bag. The connection system includes a dust bag 1 and a fixed support chain 2, and the connection system also includes an elastic quick-fit assembly 3 and an anti-off closure connection assembly 4, the upper end of the elastic quick-install assembly 3 is connected to the fixed support The chain 2 is connected, and the lower end of the elastic quick assembly 3 is movably connected with the dust bag 1 through the anti-off sealing connection assembly 4 . In the present application, a set of connection system including an elastic quick assembly 3 and an anti-off closure connection assembly 4 is provided, and the upper end of the elastic quick assembly 3 is connected to the fixed support chain 2 to connect the elastic quick assembly The lower end of the component 3 is movably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com