Forming device and preparation method of corrugated paper for zeolite molecular sieve rotating wheel

A zeolite molecular sieve and molding device technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of restraining VOCs treatment technology and the development of related industries, and improve molecular sieve loading capacity and strong pressure-bearing capacity. , the effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

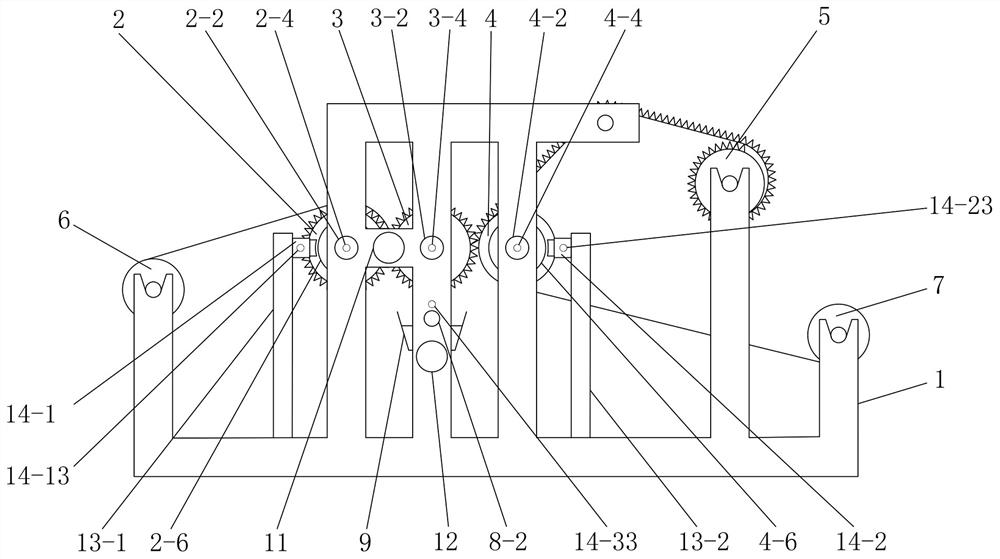

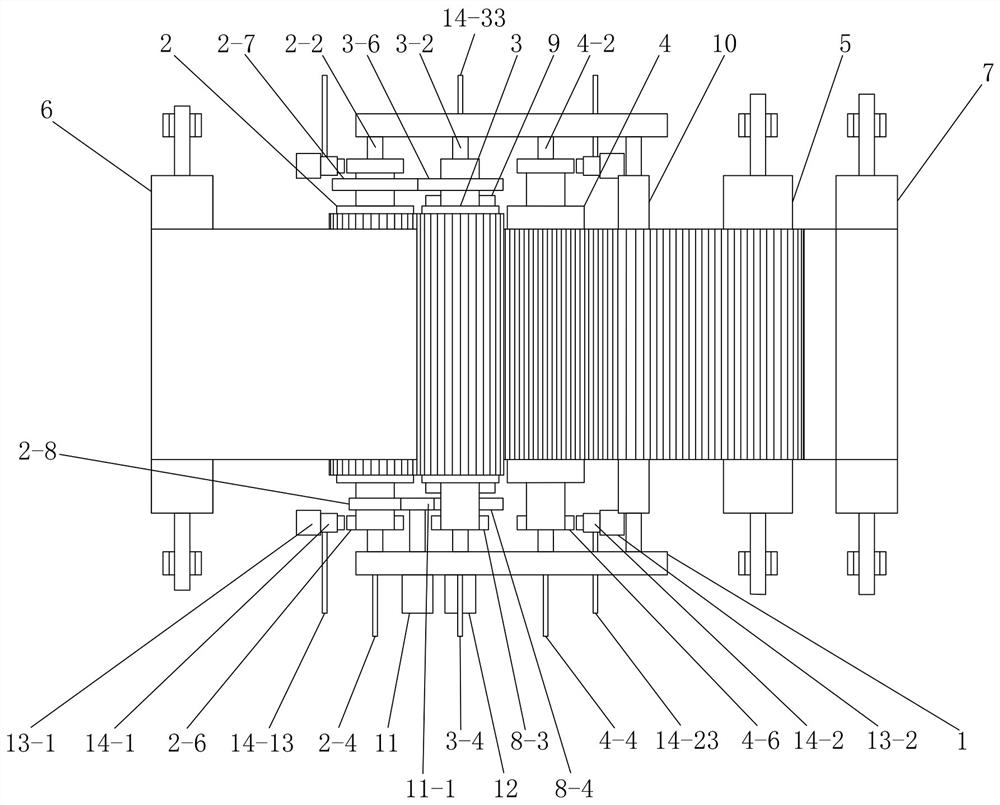

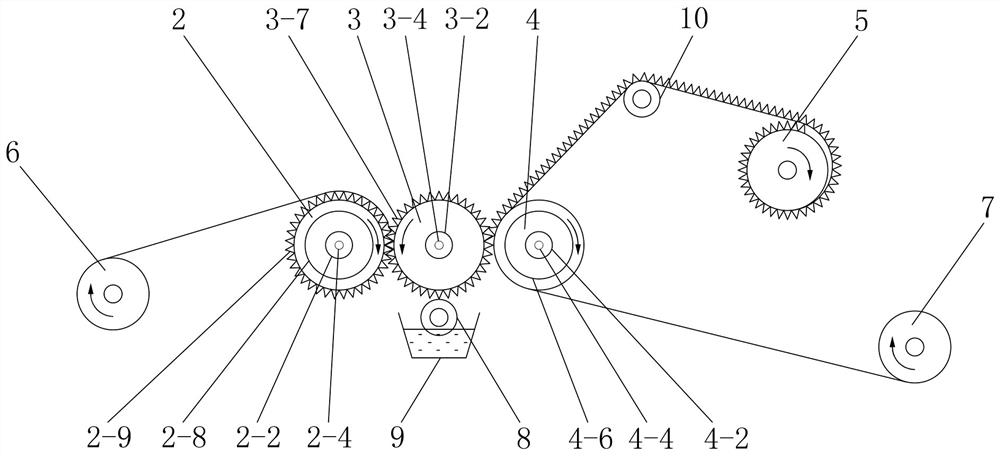

[0049] Attached now Figures 1 to 8 The structure, working principle and preparation method of corrugated paper of the forming device of the present invention are described. The left and right positional relationship between the device components mentioned in the present invention only refers to the relative positional relationship between the components, and does not limit the structure of the present invention.

[0050] like Figures 1 to 3 As shown, the present invention provides a corrugated paper forming device for a zeolite molecular sieve runner, comprising: a frame body 1, a driving roll 2, a driven roll 3, a guide roll 4, a winding roll 5, a corrugated paper roll 6, Flat paper roll 7, gluing roll 8, glue storage tank 9 and support roll 10.

[0051] The shafts of the driving roller 2 , the driven roller 3 , the guide roller 4 , the top roller 8 and the support roller 10 are arranged on the frame body 1 through bearings, and the shafts can rotate smoothly under the ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com