Vehicle tail door support rod bulb clamping spring pressing method

The technology of a circlip and a ball head is applied in the field of pressing the circlip of an automobile tailgate strut ball head, which can solve the problems of low production efficiency, complicated operation, high labor intensity, etc., and achieves reasonable design, improved assembly efficiency, and easy assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

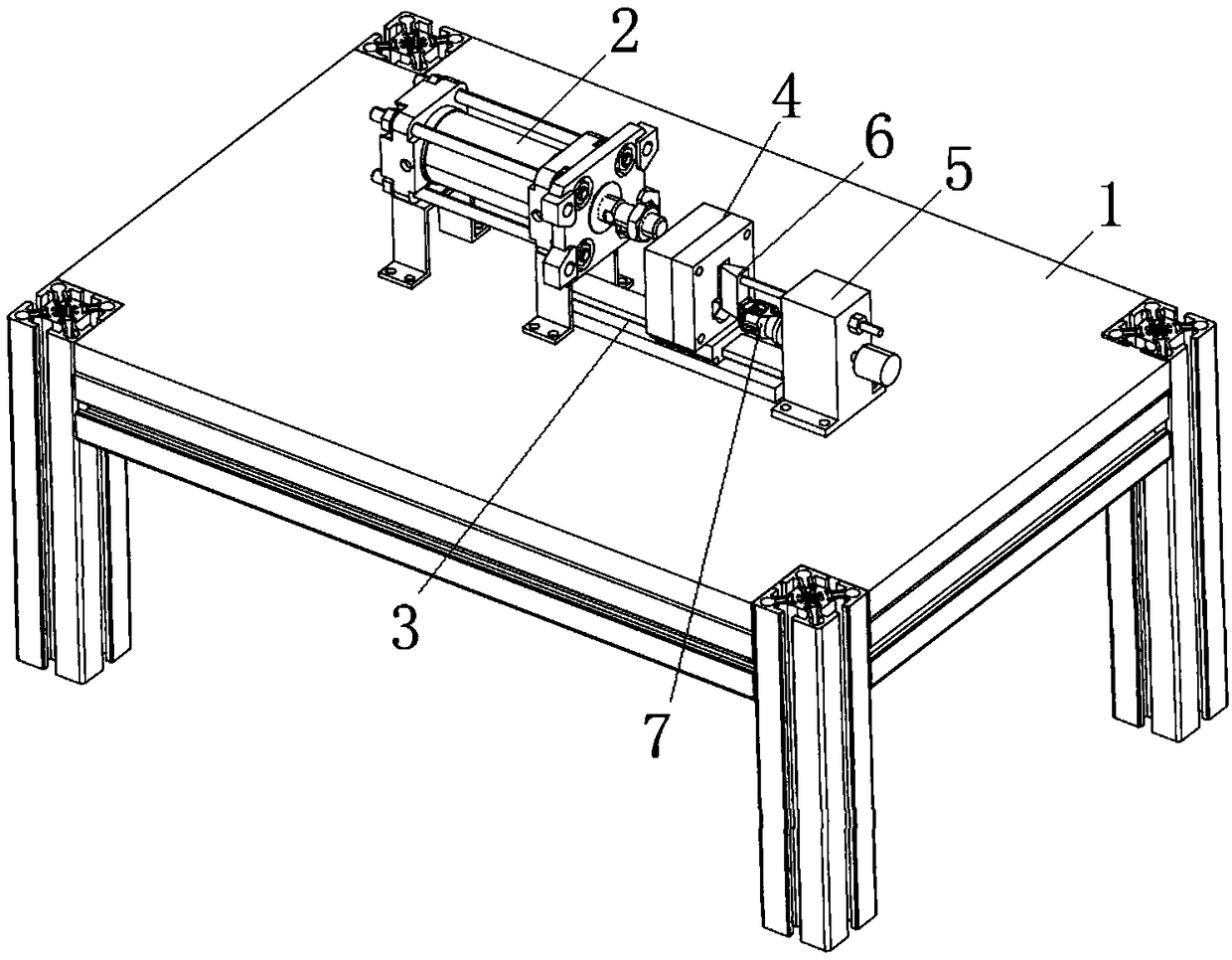

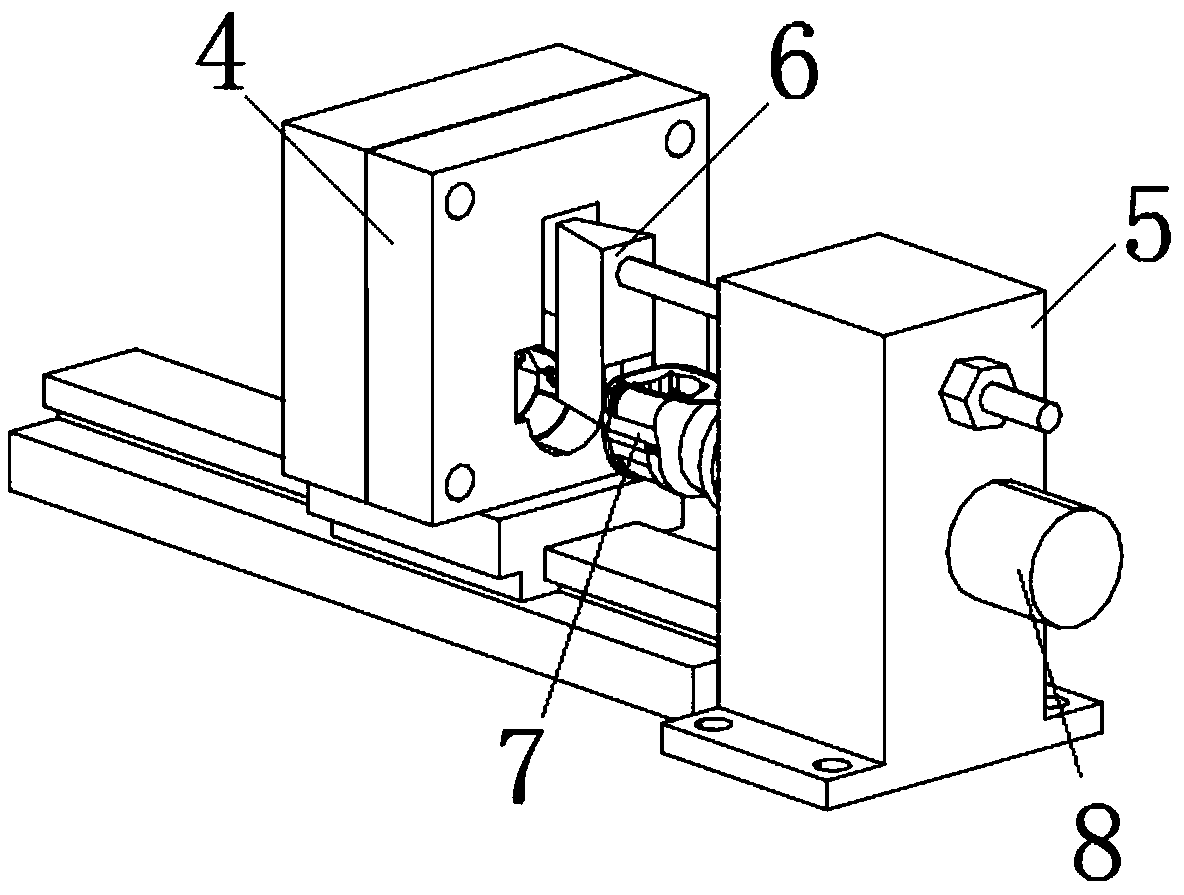

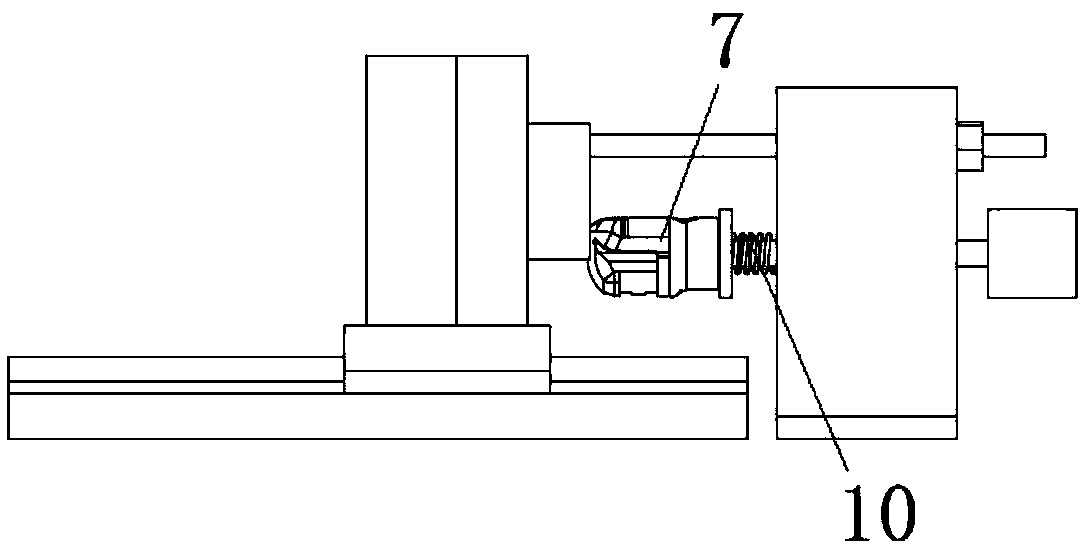

[0022] Such as Figure 1 to Figure 5 Shown is the tooling used in the press-fitting method of the tailgate strut ball end circlip, and the tooling includes a tooling platform 1, a cylinder 2, a sliding block 4 and a fixing seat 5.

[0023] The tooling platform 1 is a square flat plate, four corners of the square flat plate are correspondingly provided with four supporting legs, the cylinder 2 and the fixed seat 5 are fixed on the tooling platform 1, and the sliding block 4 is movably located on the tooling platform.

[0024] The tooling platform 1 is provided with a slide rail 3, the slide rail 3 is located between the cylinder and the fixed seat, and the sliding block is slidably arranged on the slide rail; that is, the sliding block is located between the cylinder and the fixed seat.

[0025...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com